I got some arrow the wrong way around!

On closer analysis and a good think (and remember to being on site) I have realised I over-simplified the problem at 5 Broadgate with the Macalloy hangers.

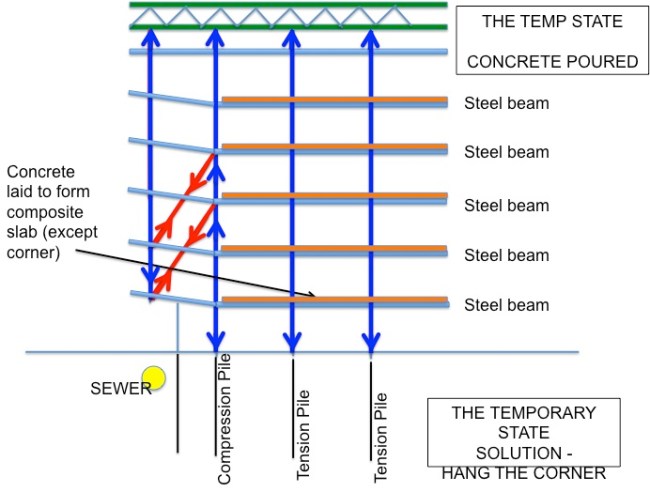

Here is effort number two. The main changes being that the Macalloys are used to pre camber the steels prior to the concrete being poured. On pouring the concrete the hangers & truss will deflect (deflection 1). The Macalloy is then released and the decks deflect further (deflection 2). Ballast would additionally be loaded onto the corner to represent cladding (deflection 3). At this point the final deflection is realised in the hanger & truss. This means that as a piece of cladding is installed on the exterior, ballast inside is removed (deflection 3 + cladding – ballast = deflection 3).

The reason for doing is, is because the designers did not design enough ‘play’ into the cladding. Once the final piece of glass is installed there would be not ballast inside and any live loading inside can be taken by the 15mm tolerance remaining.

Stage 1 – Pre camber the corner

Stage 2 – Pour the concrete in the rest of the building

Stage 3 – Pour concrete on corner is one day (all ten floors). Cure concrete. Release Macalloy. Load floor with ballast.

Stage 4 – Final deflection realised.

So the macalloy bars are there until the composite beams are formed and able to work; then these beams become propped cantilevers with the prop as the peripheral column in tension supported from the roof level truss which remainsin place. All makes sense