Archive

Getting started in Aberdeen

Despite the attachment to BP being on the fourth turn of the handle it feels like things have got off to a relatively pedestrian start. Perhaps this is because I’m used to military handovers where your predecessor can’t wait to get away fast enough, and they purportedly cover all you need to know in a one week HO/TO. It seems that BP are keen that I’m properly trained first before I’m given any real responsibility, which I suppose is a good way to do business. And so, I have spent most of my time conducting training to become a project engineer as well as attending as many meetings as possible to try and glean as much as I can from how others do their jobs.

I have been assigned to the Clair Installation team within Projects and Modifications, which is the same team as Imran. You can see a picture of it below, which so far is as much as I’ve really seen.

Team America!

Last week saw the ‘topping off” ceremony for the HQ project. ie the last piece of steel being lifted and fixed into place…this is a common-place all in team love session! Designers, struct engrs, clients etc travel from miles to come and put their autograph on the steel; work across site stops while all workers gather for a quick TY from the PM and Site Engr. With stars and stripes fluttering in the wind the graffitied I-beam is lifted and fixed into place – completed with a compulsory face stuffing session of sodas, subs and cookies! Good stuff for team bonding!

Now that temps are more like spring/summer (despite a one night sudden sub-zero drop and more snow!!!) work on site this week is going full steam, although I’m starting to believe more and more that there’s no way the contractors are going to meet the deadline of occupancy in 14 months – the pre-cast concrete curtains are still to be fitted; awaiting site clearance for space and lots more steel fabrication and welding. Though the contractors wont admit it to us, it is becoming evident they are under pressure particularly when today they started dropping rebar on the 3rd storey without finishing the steel connections on the ground floor! I look forward to the schedule conference in a couple of weeks. Concrete has been laid on ground areas A-D, while steel and formwork are being set-up for the foundations for the amphitheatre.

I am STILL awaiting approval for access to USACE computer systems and to have an email so I continue to be rather ‘impotent’…8 weeks after arrival in country…the top brass have now waded in and the bureaucratic system is slowly starting to move so I have been told it should be by the end of the week! In a contd quest to make the most of it I joined one of the PEs on a pre-bid meeting/visit to a levee repair on the northern Pennsylvania/New York border (a 9 hour round trip in a day!). Levees are big ticket items that regularly involve congressman wading in to deal with complaints raised by local residents. I have been absorbing issues of staged construction, repair, grading, erosion and sediment control (E&S) as well as nuances/issues of the ‘Public Law 84’. I was amazed at the accuracy of grading and levelling needed on the 14500 miles of national levees…one slight divot or undulation and a river can target it and rip it open when in flood. Below is a completed levee repair (protecting the town of Athens) that is awaiting spray-seeding; note the grading of 1:2, rock armour at the toe, grass matting above the toe to control erosion in the interim. The remaining matting has been blown off in recent storms.

QUT CIP 2 – Blog 1

Well despite only having been on site for a couple of weeks, I feel like i have enough to warrant my first blog.

Project. A $60m contract to build a creative industries precinct for the Queensland University of Technology (QUT). The project is to construct a multi-purpose education facility comprising of teaching spaces, office accommodation and specialist teaching studios for the creative arts faculty (music, dance, drama and visual arts).

How the finished building should look.

The project comprises 3 Lots; Lot 1 – an upgrade to the existing plant room in another QUT building, to provide sufficient additional output for the new buildings; Lot 2 – a new, high tech, six storey building containing dance studios, study areas, research and support facilities etc; Lot 3 – the restoration of three heritage listed single level timber buildings and the construction of a single level building, all to house a visual arts facility. Ultimately the building will act as a hub for the hundreds of lycra clad hotties you currently find around Brisbane.

Environmental Issues. As an added complication, the site needs to achieve 5 stars under the Green Building Council of Australia’s (GBCA) Greenstar initiative, which places restrictions on the build in 9 areas; management, indoor environment quality, energy, transport, water, materials, land use and ecology, emissions and innovation. One of my tasks to date has been to ensure that the electrical cable schedule for the build complies with the PVC best practice guidelines – fortunately I had a visit from KY last week so I could draw on his vast knowledge of all things PVC!

Contract. The contractual setup has John Holland Group as the principal contractor under a construct only contract. The work is all being done by sub-contractors so John Holland Groups role is essentially coordination. At the minute, as we are still building the structure and not yet installing services, it feels like John Holland Group is just passing messages between the sub-contractors and the design consultants (via the architect and the project superintendent). I’m sure we will start to add more value when we start installing the services in the next few weeks.

Team Composition & Structure. As we are co-ordinators on the project, the team is a small one with just 4 site engineers reporting to a senior engineer, 3 site foremen who report into a site manager and a 2 man commercial team reporting to the commercial officer. The dynamic can be challenging at times as the structure has the foremen and engineers in separate reporting chains. There are frequent communication frustrations between the foremen, who seem purely interested in pushing the programme and getting ahead of time, and the engineers, whose responsibility is it to ensure adequate checks are carried out before each concrete pour and to ensure arse covering the paperwork is in order. Neither the organisational structure, nor the site manager (an ex-foreman), force the foremen to keep the engineers updated on programme changes. As such there will be an almost daily unplanned scramble to get inspections done and paperwork signed. My attempts to get both parties to update progress/changes on a whiteboard on a daily basis have made some improvement to this, albeit reluctantly on most parts.

Subcontractors. I will wrap up this blog with a picture I took at an off-site inspection of some electrical kit I went to. I’m not sure what the orange box in the background is, but the young lass in the foreground is the electrical design consultant. Not bad!

Main Switch Board Inspection

Social. It’s pretty rubbish out here as you can imagine. I’ll just post a couple of pictures of the horrors I have had to endure.

Playing bowls with Pete at my local club. Cooking shrimps on the barbie with KY.

Driving my Ute on the beach. The missus making me touch the top of a mountain!

I’m on leave now for a week as the site is closed for the week between Easter and Anzac Day, so will blog after the CI’s visit.

Structural Engineers ______________

This week for me has been somewhat interesting.

The project director for the South Bank Tower, Shaun Tate, has gone on leave for three weeks and the duty seems pretty out the loop with what is going on. Therefore the Major Projects Director for Mace has gotten involved to sort out any problems!

Well, we have a few problems! So today the Major Projects Director sat through a temporary works meeting between Mace, PC Harringtons (sub contractor for the core sliupform), Walsh Group (temp works engineer) and AKT II (the Structural Engineers). Normally there are six of us in our weekly meeting. Today I counted thirteen at the table.

At discussion was the metal plate that attaches the 3 x Macalloy hanger rods (carrying up to 7600kN ULS force between them) to the reinforced concrete core. Now steel to concrete connections are the Structural Engineers (AKTs) bag. They (AKT) are meant to own this. Sadly for AKT they have so much already on their plate they’ve given us no time to sort this out. And by sort this out I mean determine the detail. How will this work? How do we build it! This has meant that instead of sorting the problem out at the appropriate level (meeting of 5) we have everyone at the table (meeting of 13 including the client).

Well the outcome of todays meeting was (thankfully) generally positive. The work I had done this (and last week) to understand the detail of how the rebar (in the wall) between, above, to the side and below the plate interacts with the massive hangers seemed to pay off. AKT ended up having a long list of ‘to dos’. (This includes re-designing, de-conflicting the rebar and providing some direction). The slipform does not appear (as yet) to be delayed any further than the 17 April 14( to depart from Level 30). So all is good.

What I have learnt from this is how work shy and sloppey shouldered Structural Engineers can be!!! Perhaps this is a little harsh. But I am starting to understand the friction of relationships between contractors and designers. Designers are short sighted and ignore the real world problems. Contractors only shimpf that Structural Engineers will not consider the temporary state and only ever design un-buildable structures!!

The outcome is that Mace do not trust AKT. AKT haven’t a clue how we are trying to execute the build so just choose to ignore the issue until it is escalated to such a level that they cannot ignore it! Fun fun…..

Thankfully tomorrow is Friday! My apologies for the long post. Rant over.

Back in the game!

Well I made it back to London this week and back to work on Monday. The foot is on the mend and I have now progressed to the B3 Cbt Engr post final exercise hobble! All of my x-rays have now come back fine and I am now encouraged to walk but it is still a bit uncomfortable. It takes me twice as long to get to work as I have to walk slowly to the bus stop and site office but hopefully it will be back to whacky races on the bike again soon. At least my foot looks like a good bit of engineering now with it’s 3 titanium bolts!

I am now office bound for a few more weeks until I can squeeze the hobbit foot into my work boots but I am still covering the utilities installation. I have picked up a few technical issues that need sorting out before we can finish off our drainage. We are planning to pipe-jack a 450mm concrete pipe 70m under Battersea Park to the mains sewer. Our sub-contractor (O’Keefe) have a sub-sub-contractor (Perco) lined up to do the work and as far as we were concerned they had a plan at least pencilled in. I was a bit concerned to see an email from Perco asking O’Keefe to clarify the ground water level as the latest and closest borehole information didn’t show a GW strike in the first 10m yet another borehole further up the site hits water around 3m BGL. I found this latest borehole data very unusual as around 20m away we had been striking water at around 3m in the drainage trenches and it was p*****g in! So today I have been doing my own desk study and gathering previous borehole information that is on Aconex-our data sharing site and getting the latest data from the client’s representatives. Low and behold all previous boreholes along the south of the site strike water at around 3m BGL either in the River Terrace Gravels or Alluvium Clay above the gravels. The area at the south end of the site is a bit unusual as it was a reservoir with filtration beds in the 1800’s and the back fill has been a variety of materials. I think the latest borehole didn’t record the groundwater accurately for perhaps 2 reasons: they were using water between 1-5m to lubricate the cable percussive borehole machinery, or the fact that we were dewatering our drainage trench around 20m away at a rate of 7L/s. Either way it doesn’t look like a good borehole to use for design (John-triangulation I hear you say!). I am also a little concerned that Perco have said that they would have problems conducting pipe-jacking with a heading in wet granular soils due to the likelihood of ground loss. I have put my findings to the senior engineer at Buro Happold who has been designing the drainage and hopefully he comes back with some advice on the design borehole that Perco should be planning the works to.

Around the rest of the site progress has been made and here is last months time lapse video:

http://vimeopro.com/user25873713/battersea-power-station

In the Cam 96 video you can see my retaining wall for the road going in by the railway arches. In the bottom left the cofferdam for the pumping station has been excavated and propped using a Mabey prop system and finally the concrete rings have gone in but I missed that excitement. In the top left corner John would be getting excited with the props, waling, thrust blocks and excavation of the cofferdam, so far the sheet piling has moved 20mm and there is only 5mm more allowed. We are not sure how accurate all the monitoring measurements are though because someone has hung a water pipe on the wall using the survey targets! The piling rigs are still working hard and the sub-contractors are still constantly arguing over pile mat handover and areas to work in.

Greg would have a field day!

The last blog saw me having a few issues identifying the contract that was in place for the £1.2 million of waterproof membrane which we will be spraying in permanent works beginning on the 3rd Jun 14.. Turns out there wasn’t one…

I am determined not to use this blog to drip about the complete mismanagement of this process…I’m beginning to bore myself. So instead I will detail some of what I’ve learnt and try to tease out what John would call, ‘CPR gold’.

1. Statement of Requirement. The specification designed by the MottMacDonald Ltd is linked here. 16 Section KW20 Materials and Workmanship Specification – Spray Applied Waterproofing Membrane Systems for SCL Works

The performance requirements are at para KW20.1301, and Table KW20-03 in the appendix. In outline they pertain to bonding properties, permeability, crack bridging and flammability.

2. Preferred suppliers. In the beginning, 4 chemical materials companies were under consideration. I hesistate to use the term preferred suppliers, as there is a slight nuance here.

a. Subcontractors. Blokes doings things with kit and materials. The Joint Venture will invite subcontractors to tender for work, using this website. Designed for use at the Olympics, it has become industry standard for major capital contracts to ensure transparency. Subcontractors then accept the invite and are added to a list ahead of a commercial comparison, eventually leading to a subcontract, in this instance in the form of NEC.

b. Suppliers. Just stuff. A materials requisition report is raised from BFK and sent to a list of suppliers. This process is much less transparent and very much favours older, larger, richer and more established companies. It follows a process reliant on old contacts and who we have used before, combined with a quick Google search. We let them know we are looking, and suppliers then tender for the work, are compared, and a decision is made culminating in a supply order.

For the waterproof membrane, we are in a very grey area. In essence, we are ordering material alone, which should put us in point 2b territory. However, we are also hiring their machine to apply it AND getting a techical expert to train us. This training really should stray no further than the classroom, but he is already operating underground…applying the material in a trial tunnel…that is in fact going to be a cross passage…that will be inspected and signed off as permanent works. This strikes me as a professional service and one which should be protected by the assurances commensurate with a subcontract.

3. Commercial Comparison. The four chosen suppliers then underwent a commercial comparison, the output of which is here: Commercial Comparison. The churn of people in this place is such that the people that were involved have all left, so I have tried to pick out the decision making process (I’ve hidden the names to product their commercial modesty so if you’re having trouble sleeping, play along at home and see if you can work out who we went with.

a. Specification. Clearly, the first criteria test is if your product meets the spec.Although all state they can, one was unable to prove it. The eagle eyed will note than one actually does not meet the spec on permeability. His waterproofing is not waterproof which you would have thought would have harmed his chances…

b. Experience. Previous case studies are all important, and if you can say that your product has been used successfully on previous high profile projects, it will stand you in good stead. Additionally, the tunneling fraternity is quite small so it is likely that some of those making the decision will have worked on those jobs. Definitely the case here, and you will note on this critieria, one supplier is the clear winner.

c. Cost. I remember Greg saying that the cheapest and most expensive tenders are often stripped away straight off the bat. In this instance the most expensive is prohibitively so, and as such put himself out of the running. Although the original budget is lost in the mists of time, we are now looking at projected costs for this work for the purposes of the materials requistion.

d. Add Ons. In order to further mitigate risk, the supplier may offer supervsion, training WITH accredition and ongoing technical support. For us here, this is critical. There is very little knowledge on the product or the equipment.

How did you get on? Hopefully you all went with Supplier 3…BASF with MasterSeal 345… because we did and its too late now. The irony is however, we’d already signed up to the automated machine…the Logica….BASF owned which can only use the BASF products so it seems this process was slightly moot.

In other news,

Thermal Trials. The thermal imaging trial has rolled out on site this week. Feedback was positive, and having delivered a number of ‘toolbox talks’ it is reassuring to note that much like your average Sapper, the miners were really only interested in how expensive the kit was. I am awaiting data feedback, but check out this footage of the shotcrete being applied to the crown of a tunnel.

Note:

1. The shotcrete begins to react in the air immediately on leaving the nozzle. Note, the reaction as it accelerates when on the surface…its is easy to see the contrast with the cooler concrete, which will immediately identify concrete which is not curing and thus areas of risk

2. The rebound (waste) actually amounts to quite a bit. In the dust of the tunnel this is often not noticed to such an extent.

Rugger. I turned out for the Joint Venture v CrossRail(and ringers) at the hallowed turf of the Honourable Artillery Company ground in Moorgate. After some pretty fruity tackling interspersed with moments of sublime and ridiculous, we ground out a 10-5 victory. Check out the first 5 mins…you will note my slick hands, sublime running lines and stonewall tackling are mainly obsured by a fat bald bloke in a wifebeater.

Progress on the South Bank Tower

As an update to what is happening on site here is a summary:

The Tower:

The level 29 and 30 slabs have now been poured.

PC Harrington and Slipform International are constructing the slipform rig at level 30 with a deadline, of only one week now, prior to the commencement of the slip (to level 42). This is expected to take 6-8 weeks.

Tower Crane 1 which services the tower was climbed last week to 130m without any problems. A third tie at level 28 was engaged to do this. Cladding is starting to be installed too, between levels 1 & 15.

TC1 Climbed to 130m above ground (TC2 is the small one in front)

North Basement

The north basement excavation is down to stage 1, +2m AOD. (Existing ground is +4m AOD). The first whaler is in place and the props are being installed.

The North basement excavation

West Basement

I approved the temporary works last week and work should begin this week to install a sheet pile retaining wall. Work will then begin to construct the ground level slab prior to top down construction. (In the near-ground is the dewatering well be driven). The main issue here is that the area above the retaining wall is a logistics delivery point for concrete lorries. Agreeing a workable piling solution to allow deliveries during the excavation was the main issue and remain one to keep an eye on.

The West Basement excavation. In the near ground is the dewatering well and piles for a 10 storey central atrium core .

East Basement

In the East Basement the B1 slab beams continue to be poured in preparation for top down construction. However this is still no temporary works plan in place for the excavation as Sheet Piling UK (SPUK), who installed the sheet piles, have rejected PC Harringtons temporary works plan. SPUK were not happy with the amount of deflection in the piles since PCH were not planning to prop between the B1 and B2 slab. (The piles in a place are a PU22-1 pile, 450mm in depth).

The East Basement B1 beams. The welder is preparing the top plate for a plunge column.

In summary:

It has been a busy last few weeks on site for me. Temporary works sign offs are required in all areas of the site and managing this has been interesting. There are still significant question marks about how the tower will be built. We have to leave six large pockets in the core when the slipform climbs the tower. Into each pockets a pre-fabricated steel hanger will be inserted. From this, Macalloy bars will be hung that support the 12 new storeys above (like a drawbridge works). The main issue is the installation method, size of pocket required and the temporary stability of the tower with the large pockets. I have proposed infilling some voids in order to provide vertical and horizontal load paths and this is now with a consultant engineer to model. Bearing in mind we only have one week prior to the commencement of the slip deciding this is critical. The first pocket is at level 33 so we don’t have long to decide! Other issues include how the first six floors from level 30 are built. The capacity of some existing permitter columns outside the core are near 100%. Therefore we need to engage the Macalloy hanger as soon as possible.

I am in the process of preparing a more detailed blog on this issue of Macalloys bars, hangers and post tensioned slabs. It could be a possible subject for the first TMR.

In other news I ran the Paris Marathon this weekend in 4 hr 4 mins and 43 seconds.

Concrete Bicuits and Big Cheeses

Monday began with the breaking ground ceremony with a veritable smorgasbord of big cheeses in attendance all vying to be in the seat of the clamshell excavator for the corporate picture. When instructed to put up “loads of signs” on the site the lads took this to the extreme and I invite you to count the number of Lain O’Rourke signs in the picture.

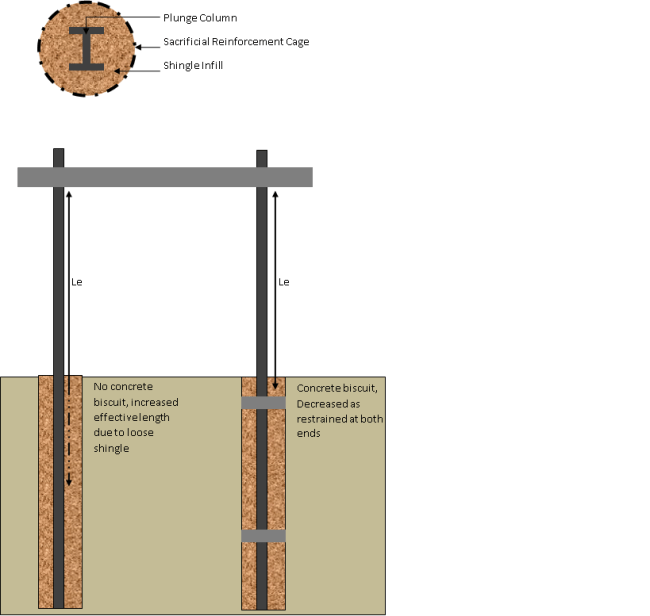

I feel it is probably an appropriate time to explain the construction method and some issues that I/we will face with the construction. The Blomfield box is a top down build. In this case a contiguous pile wall has been augured and poured to a depth of 70ish metres. The first main slab was poured two weeks ago and we are now excavating beneath the slab. Each subsequent slab and excavation will be complete in the same sequence; excavate, pour working surface, fabricate reinforcement cages, pour concrete slab and beams and then excavate through and beneath to the next level. No columns or walls will be constructed until the final level is completed at the 71SSL. All walls and columns will then be constructed working backwards towards the surface. As a result the slab and beams are required to span a gap of 25-30m in places. With no columns or walls beneath the beams the entire slab will be in tension throughout the duration of the excavation. In order to reduce the span steel plunge columns were cast into a steel cage and then backed filled with shingle. The 40m plunge columns act as intermediate supports for the slab during the excavation and then will be cast into concrete when the remaining walls and columns are constructed. During the excavation the steel plunge columns are to be exposed and are then at risk of becoming slender columns and buckling. In order to overcome this two mitigation methods have been applied firstly the max load on the slab has been limited to 5kPa and secondly the steel columns have had concrete biscuits cast in to reduce their effective length during excavation.

The drawing below shows each level of excavation, approximately 6-7m and the columns once exposed between levels and prior to the construction of the slab are considered to be slender columns if not restrained. In order to overcome the problem that over excavation and to ensure the column is restrained concrete biscuits 1200mm deep were cast around the plunge column thus reducing the effective length and making the columns stocky. Problem solved.

The Rise (and Fall) of the Machines

My main focus over the last two weeks has been the planning and execution of the trials of the water proof membrane layer of the Sprayed Concrete Lining tunnels. Following the application of the initial layer of spray concrete (min 75mm), which stabilises and regulates the substrate, the primary layer (between 250mm and 350mm) , which is comprised of the same concrete mix, with steel fibre reinforcement to provide the main structural element of the tunnel the waterproof membrane is applied. This will subsequently be ‘sandwiched’ by secondary layer and finally a surface layer which I will not discuss here. See drawings Typical Lining and Thicknesses

The ‘Eye of Sauron’ is now on this section of the works, and I have lost count of the amount of times the client side have reminded me that we dont want to be standing on the platform in a few years time next to a bucket catching the drips from the lining. The chemical is polyurethane based, and is delivered as a white powder in 20kg bags. Designed to be used in hand or spray application, the powder is mixed with water and applied to the lining as a paste, which then cures to a material of the texture of a hard rubber. The lining is applied to a thickness of 4mm, which leaves a smooth and shiny finish.

Logica spraying MasterSeal (Top)

Inspection of MasterSeal layer for compliance, alongside MottMac Designers (bottom)

Concurrently, a spray application machine known as the Logica has been procured from BASF, one of the suppliers of waterproof membrane. This machine not only doubles the rate of production, but minimises wastage by its ability to automatically spray to a pre programmed profile. The trial of this machiine was observed by a number of nozzlemen who obviously felt consigned to the stoneage! However, the procurement of material and machine have thrown up a number of interesting contractual notes.

ISSUES

1. Logica.

A flat bed lorry carrying a hose arragement designed to attach to a spray concrete delivery system, applying upto 20m3/hr of concrete to the walls. Much the same as a system that already exists on site, uniquely it is has an on board automated survey system allowing it to scan a the profile of the tunnel, then apply material to a consistent thickness. Manufactured by MeyCo in Switzerland there are only 5 operational units in the world. BASF purchased one, and are seeking to procure a second. (This is important later.)

The BFK JV deemed it appropriate to rent this machine to apply the waterproof membrane across all SCL sites. A smart move given that 373tonnes are required, not including tolerances or wastage. BASF now lease the vehicleto us at a flat rate of £12500/month. The delivery to site and subsequent testing and approval then became my issue.

For someone who has now embraced Whole Fleet Management, and a few headaches aside, been impressed, I was astionished at how little we got for our money. The vehicle turned up at site having been ‘refurbished’ Despite having been given a thorough wash and wax, it immediately became clear that this had not happened , as I quickly found myself replacing water pipes and watching the replacement of a hydraulic ram on the boom. Clearly the machine had not been run up at all before delivery.

Secondly, and mainly due to the unique nature of the machine the corporate knowledge for operation is almost nil, even with BASF. It is all contained witin the head of an Austrian fellow called Kristian, who lives, conveniently, in the Faroe Islands! He nursed the machine back to life over the course of a day and night and we were back in business and now the best of friends (although I strongly suspect he may be an android!)

So….the program for waterproofing and secondary lining is now solely reliant on 1 machine, and 1 man. More to follow

2. MasterSeal.

The BASF branded waterproof membrane product. By far the most expensive element of the tunnel lining, and the the 373 tonnes will cost us just shy of £1.3million. Not only that, it is manufactured in the States and comes with a 6 week lead time. Additionally it will arrive in 20ft shipping containers, and since space on site is at a premium it certainly wont be stored here. But surely, considering the size of this order, all this will have been thought about? See below…

WHAT HAVE I DONE?

Considering the issues surrounding the vehicle, I sought out the contract to establish a what we could expect from BASF. There wasn’t one. The best I came up with was a Plant Hire Order detailing the quote and generic T&Cs. A bit more investigation found the initial invoice with an attached, generic contract from BASF which amongst other things told us that it was our perks to repair and maintain this machine AT OUR COST!

Given the lack of knowledge I organised the nozzlemen and fitters (M&E) to udergo familiarisation training at the beginning of each shift to try to mitigate the reliance on one Faroe Islander. Having directed this on the Friday, I expected 3 of the 4 shifts to have been trained by the Monday morning. Most were pulled away elsewhere !!!

Neatly slipped into the T&Cs was a clause that dictated the Logica was only to be used with BASF products…ie MasterSeal. This clearly makes it difficult to conduct a fair and objective commercial assessment of suppliers as it seems the horse has already bolted.

So based on this newly found knowledge, and a serious indicator in the fact that BASF are the only supplier seemingly in the race, I began to look into how the order was progressing. Again, there wasn’t one.

Next, I collated all the site programs, and established that the Fisher Street site intend to begin spraying waterproof membrane on 3 Jun 14, meaning that with the lead time for deliver plus a weeks contingency, the last safe moment to order this stuff is 14 Apr 14…11 days from now.

Thus, and in a mild panic by this stage, I returned to the commercial team to discuss lead times on the procurement process on an order so large. I was told and average of 2-3 months. Red Card moment.

REFLECTIONS

It seems that a limited Commercial Assessment was done in July of last year which compared 4 suppliers. BASF were preferred almost immediately despite being 2nd most expensive, as they could provide a better level of technical support, with the added sweetner of the Logica. However, since that point, nobody has been repsonsible for this section of work. This speaks to wider issueS at BFK which is thematic across the project.

Communication. Despite everybody being cognascent of the importance of this section of works, a robust plan has not been considered, resourced and properly tasked. This lack of proper tasking is exacerbated by the retincence of people to take responsibility for execution. Below senior management there is very little accountability. In this example, the commercial team have done a bit, and the construction team have done a bit and the whole process has been bounced around before being completely dropped. There is now NCO equivalent who seeks an intent, follows an endorsed scheme of manouevre, and is accountable for achieving an endstate.

So after a series of polite prompts, I presented all this to my line manager and said, we need to get this order completed, supported by a robust contractual agreement which details ongoing maintenance and technical support, and includes a training program for the guys, and guaranteed delivery times and storage for the product…and we need it yesterday. I was told ‘Ok…we best do that then…’

My Building is Burning

http://www.dailyecho.co.uk/news/11124187.BREAKING__Explosion_and_fire_in_student_block/?ref=var_0

No punchline, my building really is burning.