Archive

Programme vs Quality

This blog follows on from my previous blog about getting ready for pre-commissioning flushing. This time I will be focusing on point 4 of the check list – having a complete system.

As previously mentioned the original construction programme date for starting commissioning was 17 Aug 15. I had managed to get my elements of the pre-requisites in place and it was now down to SRW to provide a complete system. SRW did not achieve this date therefore for once CCL were in the position to be able to write a notice of delay; something SRW have been all too keen to do up until know. However it is only really worth writing a delay letter if there is actually going to be an impact on the programme (something SRW seem to have missed the point on), otherwise you are writing a letter which has little impact contractually, wastes time and erodes good will.

By sitting down with my SRW counterpart it became apparent that the date of 17 Aug in the programme was plucked out of thin air / had a huge amount of float associated with it. The completion of flushing (six week process – 1 week fill, 3 week flush, 2 weeks for results to be processed) was linked to the start of commissioning which wasn’t required until 16 Nov according to the programme, however, the fit out matrix is at least 2 weeks behind in core A and therefore this date could be slipped to 30 Nov which gave us a requirement to start filling the system by no later than 19 Oct, which is the date we agreed on to start. Buying SRW 2 months more time, which seemed more than enough time to complete the works that were left to do.

Unfortunately this time has been squandered by SRW. 19 Oct came and went and although the system was complete in that it had been installed the requisite checks that I eluded to in my previous blog hadn’t been completed: visual inspections were not completed to identify and rectify snags. As of 20 Nov the system still has not been filled. It is now looking like this won’t happen prior to Christmas – if the system is filled now we’d potentially still be flushing during Christmas stand down. What is frustrating is that this is all down to an issues of balancing time vs quality. SRW simply aren’t on the same page as Carillion with respect to the quality we will demand. They have been pushing on trying to hit programme targets and in doing so are slipping on quality. Carillion will not allow SRW to proceed with filling and flushing until we are happy with the quality of the system and therefore SRW’s approach is inefficient in that they are going to have to pay to go back and conduct reworks.

Nobody from SRW appears to be managing the quality of the installation; they are letting their trade contractors call the shots and are taking their word at face value. This became very apparent in the lead up to 19 Oct. I had been monitoring progress on site and knew SRW were going to be nowhere near ready. My counterpart in SRW said this wasn’t the case. It was only when I sat him down, explained the issues and walked him out on site that the penny dropped with him as to what was happening. Everything I have picked up is blindingly obvious to see, but the SRW manager had been trying to manage from behind a desk. Unfortunately this doesn’t seem to have changed much and some of the key issues I have highlighted are still present. Although this is frustrating it is great for me in that I believe it presents some good C2 and C3 competencies to discuss at CPR.

The issues I have picked up include:

1.Union joints on pipework only being done up hand tight. What is particularly concerning about this incident is that SRW had recorded this section of pipework as being complete and having been air tested. Which then brings into question their whole process of checking the system.

2.Pipework not being installed as per the drawings. SRW’s response to this was that the drawings are only indicative! This would be fine if we had loads of space but the ceiling voids are tight and a small fortune has been spent on BIM for them. CCL sought assurances that this wouldn’t cause clashes with other services (it was obvious it would), SRW have not provided it and it is now becoming apparent that issues are developing, which will result in pipework having to be removed. An example of this can be seen below:

LTHW and CHW flow and return pipework above the ceiling grid of an apartment. The pipework had not been installed as per the drawings which means the lagging is now clashing with the flat duct work.

SRW’s solution to get around the clash between CHW pipework and the flat duct work is to use armaflex (black lagging above) instead of the normal Kingspan (silver), which isn’t acceptable. Why not? The employer’s requirements detail a specification for lagging on pipework which details the thermal conductivity of the material and thickness of insulation dependant on size of pipework. In this case the armaflex fails on both thermal conductivity and thickness. Although a 1 m length of sub standard lagging is unlikely to impact on the performance of the heat interface unit the main concern is that we are dealing with CHW pipework. Sub-standard insulation may lead to condensation forming on the lagging which will drip onto the ceiling and eventually result in a stain.

3. Clashes which prevent valves from operating which would prevent filling and flushing from taking place as per the RAMS.

My involvement in this element of the project has reinforced conclusions that I have previously drawn: the importance of getting out on site and looking at the progress of an installation on a regular basis, not just when it is offered up at an ITP hold point can not be under estimated. In addition far more information can be gleaned by talking to the bloke doing the installation than the manager of a main sub-contractor.

Non Commissioned Officer Academy Ft Drum

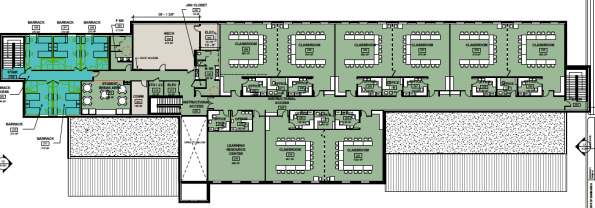

The NCOA will be a mixed use building to house routine NCO promotion training, similar to the Royal Engineer Section Commanders’ Course. The building will house the instructional classrooms, administrative offices, some accommodation, an auditorium, changing facilities and personal weapons storage. It will also house a 15 ft high training area (Room 140 on Figure 1) to be used for drill practice and physical training when weather precludes it from being conducted outside.

Figure 1: Ground Floor Plan.

Figure 2: First Floor Plan

The project proposal form had to demonstrate the need for the building, which was that it will replace twenty World War II temporary structures. This will result in a better training environment and reduced utility and maintenance costs. The new building will cover 45,700 sq ft and the project value is currently set at $19 million USD. In order to justify this cost a qualitative economic analysis was executed looking at the alternatives of renovation, maintaining the status quo, leasing and new construction. The status quo was deemed to be unacceptable and other alternatives would have only been a temporary solution.

The project is being contracted as a design, bid, build and the design timetable is organised such that the build contract is due to be awarded on 30 September 2016. This is the last day of the current financial year for USACE and so allows funds to be attributed from this financial year. This presents a risk because if the contract is not awarded on this date then the money attributed to this year will need to be spent on another project or will be lost to the Garrison. I am not privy to information on other mitigating circumstances at programme level, however if some float time had been built into the design schedule this would mitigate the issue at project level. The current design schedule has the following significant deadlines:

35% Design Stop – 18 December 2015.

35% Design Review Conference – 20 January 2016.

65% Design Stop – 28 March 2016.

90% Design Stop – 2 June 2016.

95% Design Review Conference – 28 June 2016.

The date of the planned 90% Design Stop means that I should be able, negating the chance of delays, to see the design work through to this stage.

Given the date of the 90% Design Review Conference it is unlikely that I will be able to see the design through to this point, although the most important experience will have been gained by this point on the design front. The contractual affairs will be dealt with by USACE NY District so there will be no loss of experience by leaving at the 90% design stage.

The design team structure being used by USACE for this design is spread across two USACE Districts and a Design Consultant located in three separate States. The project and the Project Manager is stationed at Fort Drum, NY and is part of NY District. Therefore the design contract naturally falls to NY District’s Engineering Division. Therefore the Design Manager, Architect, Plumbing and Electrical elements are from NY District’s Engineering Branch. Because NY District had insufficient staff to conduct the design of the structural, civil, mechanical and fire protection elements requests were sent to the other Districts within North Atlantic Division. From these Baltimore District was able to staff the Mechanical and Fire Protection elements. As no districts within the Division could support the civil and structural elements these were subcontracted to Pond Consulting, a design consultancy based in Ft Worth, Texas.

Because of the extended lines of communication liaison has already been difficult. A notable occurrence was the design model having to be rotated as it was created 180 degrees out of orientation. As each of the designers across three sites had different linked models this took a week of emails and phone calls to rectify. The issue would have been mitigated against if a central BIM manager was employed on the project, however neither Baltimore nor NY District currently have the post filled.

The new building is to be built on Fort Drum which is in the North of NY State for which the design temperature ranges from a winter design temperature of -30°F to a summer design temperature of 90°F. Significant measures, such as the inclusion of glycol in the hot water system, will have to be taken to ensure the winter design temperature can be met without causing equipment damage.

My part in the design will be to assist the mechanical engineer, Tim Wheeler, in the design of the HVAC system for the entire building. Work for the 35% design is a simple design analysis, setting out of the mechanical rooms, as shown in Figure 3, and specifying the HVAC system type. At the 35% design the room layouts, and therefore volumes, should be fixed to allow the detailed design to take place.

Figure 3: Mechanical Room at 35% design, the eagle eyed will notice that it does not line up with the ever changing floor plan. hence waiting until the 35% design stop to continue.

To 35%, as they are discrete elements I have been given a radiant floor design and a Building Lifecycle Cost Analysis (BLCCA) to complete. The radiant floor will be in the training area (Room 140), which is to be used when it is too cold to train outside. The BLCCA is to assess the viability, or otherwise, of using a Ground Coupled Heat Pump (GCHP) system in place of the air-cooled chiller and 70% of the heating load, the remaining 30% being supplied by a Natural Gas powered boiler.

And that’s the situation as it stands at the moment.

Sundrop Farms Update

The head contract at Sundrop Farms splits the project into five (5) Separable Portions (SP’s). The table below is taken directly from the contract, with no further description offered in the document.

Not long after construction began on site it has become apparent that there was a discrepancy between what John Holland (JH) and the client, Sundrop Farms, believed this date actually meant. JH have always gone down the line that this is the date from which Sundrop Farm will have access to two of the greenhouses (10 hectares total). After which the client will begin their fit out of the greenhouses, which includes approximately eleven weeks of activity per greenhouse. Sundrop Farms believe that this date represented the date in which the two greenhouses would become operational, i.e. they could begin planting.

Eventually it was agreed that the JH proposal would be used. There was no further information stated in the contract for the client to point to and as the balance of plant is included under SP 4, the greenhouses could not be operational as it would have no heating (although this is not currently required). However JH have allowed Sundrop Farms access to the greenhouses early to begin the fit out in a beneficial occupancy agreement and a variation order has been issued to provide heating early (I plan on doing a TMR on how this is going to be achieved).

As JH and the client look towards completion, preparation activity for the operation of the plant is now beginning to build up. There are now commissioning managers both for JH and the client on site and a commissioning plan is taking shape. In addition the client has engaged a public relations company to publicise the project. As a result there have been a number of press visits to site, including the BBC. The competition is not hanging around either, Sundrop Farms has a ten year contract with one of Australia’s largest supermarket chains. Another large Australian supermarket this month launched a new brand of tomatoes called Sundrops, not everyone is convinced this is a coincidence.

Site wise progress continues at a quick pace. I have been running with the installation of three pump stations, the lining of the lagoons, pipe racks and now the installation of the solar tower, as well as coordinating the delivery of the mechanical equipment on site. JH have come to the conclusion that the two civil engineers on site won’t be able to absorb my work load and have had to recruit a mechanical engineer, so I guess I must have been doing something right.

With the summer months now upon us complaints from the subcontractors have switched from water logged roads to snakes, dust and heat. The temperature has steadily been rising, especially so inside the greenhouses. As a result the client and the subcontractor constructing the greenhouses agreed on a solution. They organised and paid for the roofs to be painted with a temporary chalk based paint, by helicopter. Not an easy task and I’m not sure how JH escaped picking up any of the cost. It would have been interesting to capture some before and after data to see how effective this is, but unfortunately no one took any before readings! Although last week Port Augusta was the hottest place in Australia, with temperatures exceeding 45 deg. Inside the greenhouses where workers are currently installing netting and grow wires in the eaves, the temperature apparently hit 58 deg, this was with the paint in place.