Material, Material, Material

Introduction

This blog is an update to a couple of flowline projects currently under construction. Both flowlines transport Produced Water from a manifold to two different re-injection wells and is required due to the calculated increase in produced water over the coming years. (this has been detailed in previous blog)

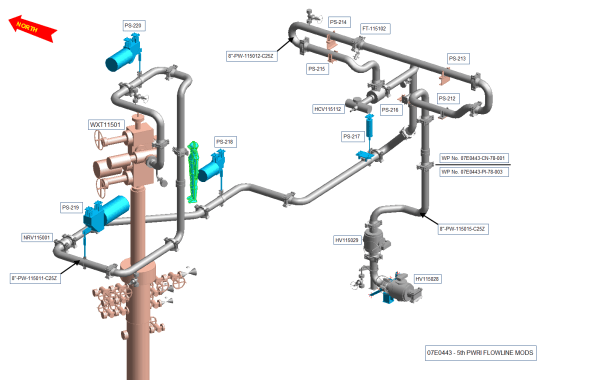

The diagram below shows the 5th flowline and starts at the manifold (bottom right) follows the shown route which penetrates different decks and supported where shown (PS) It includes a number of valves, pressure and flow transmitters & indicators and is made of a number of pre-fabricated sections (spools) which are clamped together and arrives at the xmas tree on the left (the red thing). The gummy bear represents an average height person and gives a good indication of size. In addition to what you see below, there is also a small amount of trace heating and power connection to the choke valve; hydraulic connection to two actuators and the associated limit switch cables as well as an amount of instrumentation.

Schematic showing 5th PWRI Flowline

History

The project first ‘went offshore’ over 12 months ago and has been stopped and started a few times, with different Project Engineers & construction teams throughout. The projects re-started two months ago and there have been a number of issues and testing moments…

The problems

Missing material – During the preparation for the re-start it was identified that quite a lot of material has gone missing and has had to be re-ordered over the last 2 months. It is assumed that most of the material went missing during the august outage when the flowlines were paused. It was requested that all the material were back loaded to avoid this, but that failed to happen in time, so was ‘secured’ on the platform; clearly not well enough. The missing material equipment includes pipe supports, seal rings, bolts and blind flanges. Additional cost of material approx. £50k and a significant amount of man hours required to identify exactly what was missing due to some items being offshore and some onshore.

Incorrect drawings = Missing material 2 – A decision was made back in January to add mono flanges to the A, B & C annuli (the bits that stick out at the bottom of the red thing in pic above) so that the pressure transmitters attached to the ends could be calibrated. Unfortunately the drawings were never updates (although it was requested) however, some of the mono flanges were ordered and are on the platform. Unfortunately the remainder along with the seal rings and bolts are not are and are required to be ordered; more cost and potential delay. See below pic of annuli, the mono flange was meant to be placed before the pressure transmitter.

A, B & C (top-bottom) annuli showing (L-R) well isolation valve, (white) double block and bleed valve, silver flange to pressure transmitter

Incorrect progress reports = missing material 3 – The whole project is broken down into job cards and further broken down into activities and this is how progress is reported on a daily basis. The job cards were not accurate and it transpires that a short section of piping was not completed (the well kill line), and the materials are missing. This is now an issue since the transition spool which connects the well to the pipework has a lead time of 6 weeks and the whole project is expected to be completed by the end of the year.

Long lead items – Some of the missing items are off the shelf but some has lead times of a number of weeks. The schedule has had to be re-arranged so that the individual items are sent offshore as they are received in time for construction, in some cases just days before. This makes a lot of people nervous since logistics in the North Sea isn’t exactly reliable; during my visit last week, I observed a supply vessel sitting 500m away from the platform for 3 days before it turned around and returned to port due to weather issues.

Valves – All valves were delivered back in January and were fully tested and certified prior to delivery. Although there are no specific guidelines for the requirement for re-testing if not installed soon after delivery, the unofficial line to take is that engineering judgement should be used to decide if a re-test is required. Unfortunately were weren’t able to check the condition and storage of the valves since they were offshore and so it was decided they would all be re-tested as a precaution; cost circa £50k, but an absolute nightmare to get them off the platform and a lead time of up to 6 weeks if not damage. It was a good job this was done, since the choke valve had damage shown below.

Damaged face of choke valve

Ops support – The operations team permanently on the platform are required to assist when there is a need for break in containment or electrical isolation, i.e. anything that if it went wrong would have a significant impact on the platform. Although requests were added to the ‘Area’ plan, the guys offshore were just too busy with other higher priority tasks and so could not assist.

As an aside, this worked in our favour since the delays due to material issues would have meant we wouldn’t have been ready for when we asked for ops support, but used their lack of availability as the excuse why we could progress!

So why did all this happen?

There are probably a dozen of more reasons why this has been the project from hell, but can be summarised as poor material control and poor management over the last 12 months.

Material control – Creating Bill of Materials, placing/receiving orders and getting it to the platform is the easy bit. Once the boat arrives it will depend on who is offloading it, where it is placed (there are a number of different lay down areas) and if Woodgroup have anyone aware of the delivery and able to take ownership of the material. It’s also difficult to ‘secure’ material. You could lock it in an ISO, if you had one, but during the TAR, ISO’s were broken into to identify what was inside and anything kept in a corner in a nice neat pile, risked being thrown away into the scrap bin during tidy up, or being used on other projects.

Installed choke valve. Note the pipe of ‘stuff’ behind and that cable tray, bottom right, is just sitting there.

With regards to material checks, they simply weren’t done with enough attention to detail. Confirmation of what was offshore was a nightmare and we couldn’t mobilise someone to check due to bed space. It didn’t help that the drawings didn’t reflect changes that were agreed.

Management – The management of these projects was not good enough. It was not through lack of intent, but the JRE responsible had his focus on a more urgent project and spent a lot of time offshore for that. It was also almost impossible to get the info required from offshore; It didn’t help that he was new to the project or that workloads were increasing due to the manning cuts. I of course must shoulder some of the responsibility since I am the SPA, although taking over the project just before the platform entered the TAR didn’t get me off to a good start.

The way forward

Due to lack of ops support, the projects will only advance as far as it can and will then pause (yet again). The remaining work, primarily instrumentation and electrical will re-commence in January, with full and detailed ops support and then roll into commissioning. All material has been received, less a few bolts and seal rings, and will be available. That being said, I have just been called away to discuss the mono flanges and the fact that we don’t actually have them!! Clearly there is an additional cost associated with the material and delays and will be circa £300k.

In other news……

– Matthew is now teething, has a cold and has just had injections = 3 hrs sleep last night.

– The house renovation is moving forward, with the extension planned to start on 7 Dec. Drawings, planning permission, Thames water approval and Party Wall notices have all taken a significant amount of time (and cash) so my advice is, if you are planning to buy a house – buy one that’s already extended! Or factor 10% of your budget and a lead time of 3 months for the above.

– Managed to get offshore last week – blog to follow

That’s all fairly epic. We have simar issues in terms of drawing changes and equipment supply, but they’re not magnified by the logistics constraints you have. What’s your document management system like? Ours generates a solid 30 notifications a day, which is impossible to keep on top of and so it’s easy for changes to go unnoticed. We also tend to find out about kit shortages when it is highlighted by Carillion that SRW have bodged an installation. I take it that the quality of your installs is much higher?

The document management is not a problem, its when people don’t make the drawing amendments, that’s the issue!

Quality of installation is not generally an issue, as the need to get things spot on is drilled into everyone, especially where there is a chance of hydrocarbon release of plant trip (although not unheard of) the problem lies with the drawings and if they are correct.

As an aside, another issue has just been raised as to the make up of the kill line, and it would seem that a miss understanding last year led to errors in the plans and it cant actually be used as a kill line because of the lack of connection. So this could require a Project Query to be raised, a re-design of the kill line, more procurement and more cost. Once I have the detail i’ll do a short blog separately.

What a mess, hope you can sort it.

John, I think if I follow this all back far enough I can probably put the majority of the blame on Maggie’s shoulders!!!

None of these issues are hard to solve, it just takes a lot of emails, time and of course cost.

I’m with John, good luck on that mess! Given that logisitics are difficult is equipment not stored on shore until all of it is available and then shipped out as a ‘project pack’ or is it just shipped out piecemeal?

I am assuming it is the latter but the former would presumably reduce losses, storage required on a rig and allow the construction/installation to be ‘war gamed’ prior to the actual work going off shore?

Henry, Yes indeed, there is a storage facility, ANSCO, up in Peterhead where all the material passes through to go offshore and is also a storage facility. The right way of doing it, as you say, is to group together all the material and send as a ‘pack’. In this instance, if we waited to do that then it would all still be onshore! We were literally going through the job cards and material delivery estimates and customising the construction schedule to fit what we had, when we had it, which also meant splitting up purchase orders. Not ideal, but we had a deadline to complete the scope. We haven’t lost anything yet though, but your right.

As an aside, material is required to be ‘available’ by the 6week gate and offshore by the 2 week gate.

With regards to ‘war gaming’ or SIMOPS!! this is done routinely but probably not through enough since we have experience delays due to other people just turning up in the same area and halting our work. Arguably it’s not normally like this, but there is an Life Extension Project happening on ETAP with many more projects happening at the same time than would normally happen, and controlled by different masters.

Mike

The project pack is a sensible idea, are there any systems in place to allow prefabrication of components into a spool piece prior to moving offshore? I’d imagine that the bigger the item, the less likely it is to be “redirected”

Mark,

The first diagram shows the joins between the spool pieces. All the spools are indeed prefabricated onshore so they can just be clamped together with the exception of the closing spools (in this case, one at each end). A vendor is employed to ‘shoot’ the closing spools (i.e. measure the exact gap) which then allows the drawings to be updated and the spools (which have already been partially fabricated) are completed; this whole process takes approx. 3 weeks. The longest spool was around 4.5m long and an absolute git to get into place.