Offshore at last

Introduction

As you may have guessed, my ‘site phase’ of the course is actually based in an office many miles from any site. Last week I finally got offshore and I was able to assist with the survey of the helideck in readiness for the lighting upgrade project due in feb, assist with the lifeboat survey in readiness for the padeye replacement project in May and ‘get all over’ the 4th and 5th PWRI flowline projects. Below are a few of my thoughts;

Movement and Arrival

Heli is the only way to get to the platform and takes about an hour. I have had to do 3 courses and a medical (including drugs test – I passed) to get this far and familiarisation videos and site inductions are required on arrival, which takes up the rest of the day. Lesson learnt – Don’t assume when crew are mobilised that they are going to achieve anything on the first day. Factor in at least a day or even two before any work can commence.

Understanding of the job

Getting out on site allowed me to fully understand the scope of each project rather than relying on drawings and pictures. Of course this is obvious, but you will be surprised when the last time any of the SPAs actually went offshore. One of the JREs I’m working with has never deployed. This is sometimes obvious in meetings when issues are raised. They will know about the problem and what they have been told, but sometimes don’t understand what that means or asks the ‘so what’ question. Lesson learnt – Mobilise during the design phase to fully understand the scope and also mobilise during construction so you can get hands on. Sam – I will arrange a visit as soon as I can after your arrival (once you’ve done the required courses).

SafeCal

Due to the Life Extension Project I mentioned in the last blog, there are more people required offshore than they have beds for, so there is a need to use Safe Caledonia, a floating hotel. See pic below. This is tethered to the sea bed and connects to the platform via a moving bridge. The platform doesn’t move (much), but the SafeCal does as it floats. This week the movement was so much that the bridge had to be lifted, stranding quite a few on the platform. Lesson learnt – There are many things which can cause delays to a project, this is just one of them.

SafeCal – Flotel. Note the bridge connected to the platform.

Heights

This is not a place to be if you are uncomfortable with heights

.

Level 1 looking down

Barriers, Barriers, Barriers

Very hot topic at the moment. As it happed I had two issues with barriers. I was working around the well bay minding my own business. When I went to leave, I came across a barrier that had been erected whilst I was working. I went to find an alternative route but couldn’t because of existing barriers all around; so I was barrier’d in. The second issue was when I went back to the same area 2 hours later, the barrier was still in place even though it was obvious that the reason for the barrier in the first place was now redundant, but meant I couldn’t get into the working area. Pic below – bit of a concern when you don’t know you’re in a working area! Lesson Learnt – Barrier control need work. I completed a couple of BOSS cards. (Behavioural Observation Safety System – used as a method for reporting incidences and encourages discussion at the point of issue)

Something just doesn’t feel right

Weather

A platform is very exposed and a combination of wind and rain can make life very unpleasant and stop work altogether if conditions exceed limits. As well as affecting the work on site directly it can also affect the delivery of material from boats, therefore indirectly affecting work on site. Lessons Learnt – Factor in Non Productive Time and make realistic. NPT of up to 45% is sometimes expected.

One of the better days. Carrying out recce on helideck.

SIMOPS

The platform is very busy at the moment, as noted by all the barriers!) There is a high risk of delays due to SIMOPS and needs to be managed properly. Even within a single project we had issues. Our original schedule showed electrical work happening at the same time as piping work which involved breaking containment. This was not allowed due to the risk of spark from the elec scope and the potential release of hydrocarbon from the piping work. Lesson learnt – Ensure no SIMOPS clash or deconflict and scrutinise schedules for internal clash.

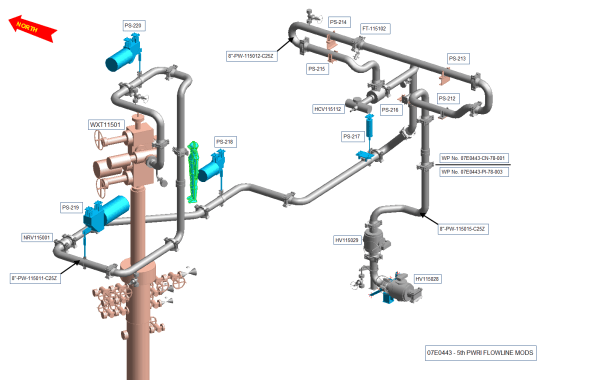

PWRI Flowline

Below are a few pics to put the flowline in perspective. In an attempt to keep word count in this blog down, see if you can ID where on the schematic the pics refer to. Questions are more than welcome. (subtle differences may be noticed between pics and schematic – ignore)

Schematic showing 5th PWRI Flowline

Picture 1

Picture 2

Picture 3

Picture 4

Picture 5

Picture 6

Picture 7

Picture 8

Mike,

At what point did you detect your SIMOPS clash between electrical and mechanical? In the planning stage or later?

Rich,

In theory and as a last resort, during the latter stages of the detailed design (DD) phase, once the work packs have been written and the intricate details of the scope is fully understood. The construction schedule is then finalised with this sort of thing taken into account, if it is indeed considered. This SHOULD be at the very least 12 weeks out.

That being said, it may be considered early on in the DD phase or right at the start when the initial project risk assessment is conducted, it depends on how experience the team is that is carrying out these activities.

I certainly hadn’t thought of this issue before, but will be something I consider in the future. Discussing with the Area Authority (permit geek) during offshore visits would certainly bring it up, hence my comment about getting offshore to press some flesh early in the DD phase in the blog.

Wider SIMOPS with other projects is considered right from the start, when the planners are trying to find space in the plan. This is looked at 2 years in advance (or more) at a strategic level, i.e. bed spaces, required works during any shut downs, any hard stop deadlines (helideck lighting being one). Then as the months tick by and the plan starts to shape, they start to look at the operational level, and the SPAs should liaise with each other to understand specifics of each other projects (there is a well workover project due in the well bay this month at the same time as the flowline project). It is also covered in weekly planning meetings at different levels.

Of course, things don’t often go to plan and you find someone turn up in your work space without knowledge; and plans are changing on a weekly basis so its never fool proof.

Cheers Mike.

Mike, can you refrain from using so many pictures on the blog, it takes ages to load up.

You still on dial up in Aus?

.Matt,

Thanks and noted. Next time I will do a descriptive piece instead.

Good stuff, the longer the better in my eyes.

Mike the pictures enhanced your description.

Thanks John, good to see someone appreciating my camera skills.