Archive

CRAC & Pipe

I recently handed back my Leadership in Energy and Environmental Design (LEED) responsibilities, which I’ve been covering for the last several months whilst the actual LEED Accredited Person (LEED AP) was on maternity leave. The timing coincided with the resolution of an issue which was high on the principal contractor’s ‘concerns’ list. It involved a Computer Room A/C (CRAC) unit and is another example of some poor contractual documentation which has led to confusion on this job. The issue has been exacerbated by the fact that the project is constrained quite heavily on what LEED points it can pursue, making those which it can particularly valuable. The issue started with an RFI submitted through the usual channels. It was labeled as ‘hot’ because it was holding up the delivery to site of the CRAC units.

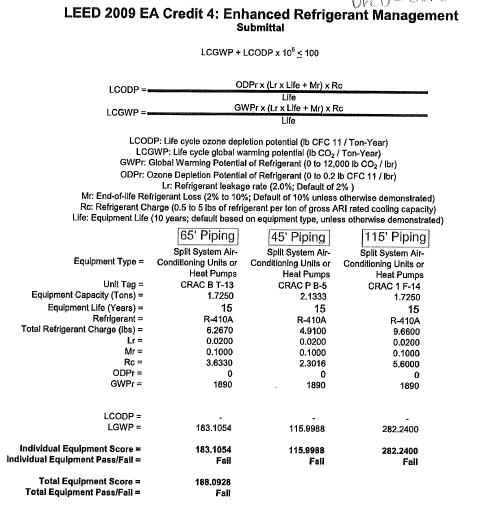

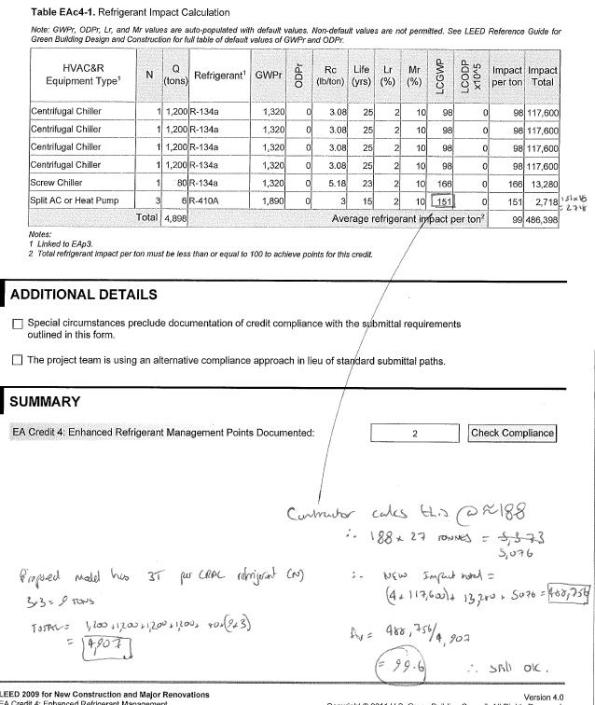

As you can see from the contractor’s calculations below the Life Cycle Global Warming Potential (LCGWP) appears to be in excess of the LEED stipulated value of 100.

After a little digging I found out that this calculation was incorrect because it was based on the three units in confinement, when the actual calculation is meant to take the whole system into account. Although these parts of the system appear to be way out of the environmental requirements the system as a whole still passes. This fact made up a part of my eventual RFI response.

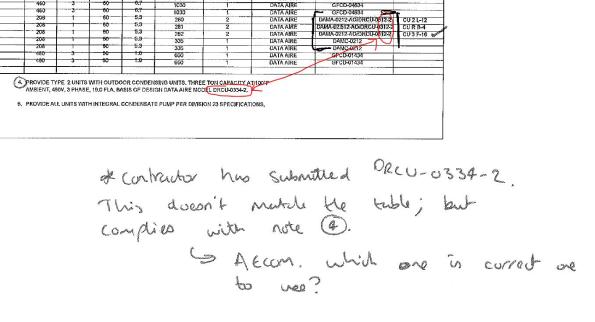

The second part to this, and most importantly is the root cause of the problem. This was in the way that the requirements were communicated; there is conflicting information on the equipment schedule. As you can see below, the table calls for a DRCU-312 unit, but note 4 calls for the DRC-334 model.

Although it has been shown that the impact is minimal and the system as a whole still passes the issue has still caused delay in delivering the CRAC units to site. This has in turn delayed the overall system installation. Fortunately this work does not fall on the project program critical path and so impacts are minimized.

This is one example of many which has highlighted issues with the contract documentation. I imagine the designer will have done some design quality control (buildability, inter-discipline co-ordination etc) but they do seem to have missed quite a lot. I expected, on a large project, that there would be some discrepancies and bits of missing information but I have been surprised at how regular an occurrence it is here. Are any of you having similar issues or is it just this designer being slack?

For me, key take aways are with respect to quality control. This is not just a site practice, but starts at the very outset of a project. It is important to control the quality of the contract documentation also, and ensure that the drawings, schedule, specifications etc are all ‘synchronized.’ The impacts of not doing so can affect all three elements of the time/cost/quality triangle. As future PQEs I expect that a large element of this will fall to us to do.

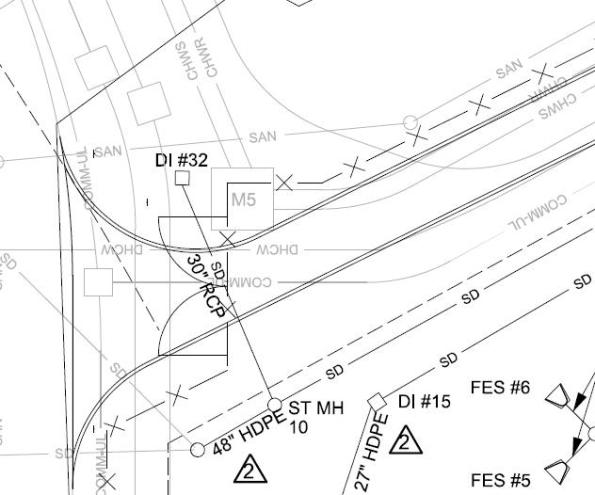

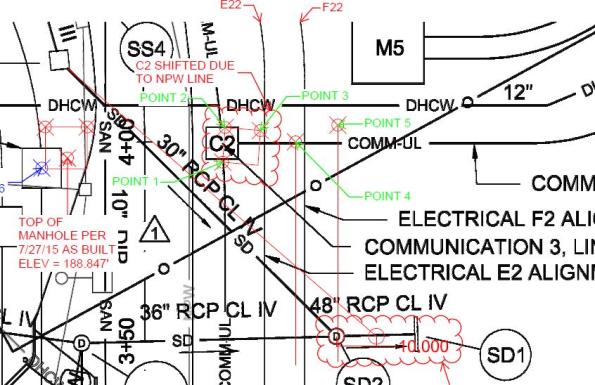

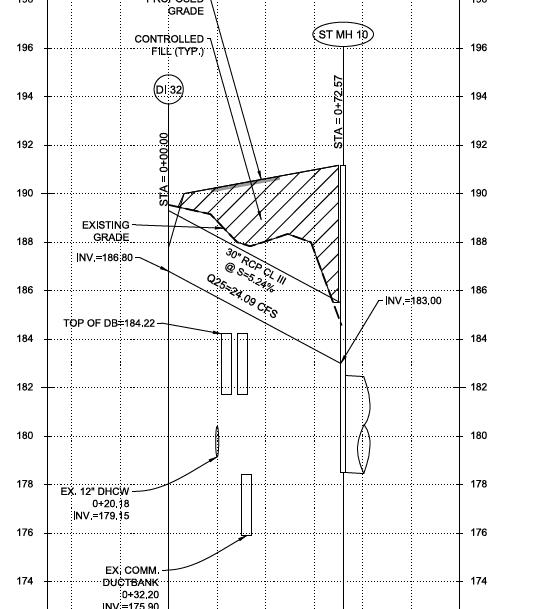

A completely separate issue, but which loosely stems from the same root is a conflict between adjacent projects. Here a drainage run from one project is required to be installed in shared space. The conflict arises due to an electrical ductbank, which is hardened, and has been installed slightly out of alignment, and at a higher elevation than design due to various other site constraints. This means that it now sits pretty much exactly where the adjacent project’s drainage run is supposed to go.

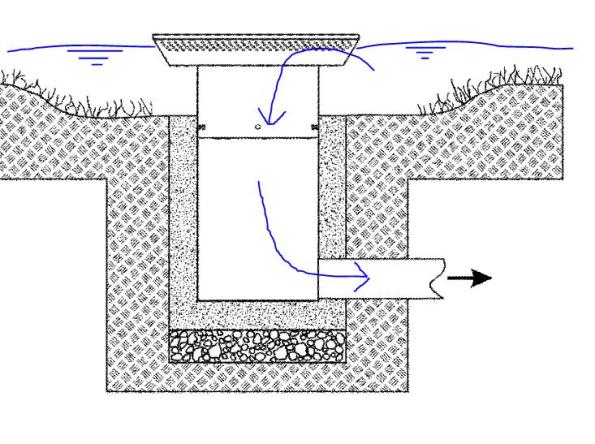

Solutions I was able to proffer were move the drainage run run to the East of the ‘M5’ structure or change the inlet type. Both solutions would require re-design / confirmation by the designer because of the potential changes to the drainage areas, and requirements for confirming flow and velocities in the amended drainage runs. The first option was ruled out fairly quickly when I looked at the elevations of some of the other utilities in the area and realized that the pipe would have cut straight through some other utilities which had already been installed. Option two was therefore looked at more closely. The designed inlet was an overflow type, quite common here and usually seen in bio-retention ponds.

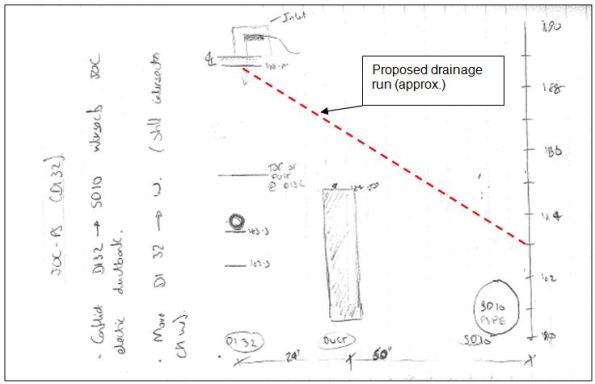

This inlet type meant that water would pond until it reached the inlet level, then enter the drainage by falling into the inlet chamber and on into the pipe where it is carried under the road (see original design above) and into the drainage system. It was the drop into the inlet chamber which was part of the problem here. By changing the inlet to a culvert instead the same function is achieved, minus the initial drop in elevation. Negating this drop meant that the drainage run could now pass over the ductbank, which it was previously conflicting with. See sketch below using, made using information from the as-builts and design drawings.

I proposed to the designer that the inlet design was changed and calculated that a gradient of around 5.5% would maintain the original designed invert of the pipe at the SD10 (see picture above) This meant that the manhole structure which had already been delivered to site wouldn’t need to be changed. Any more than 8% would conflict again with the ductbank. Steep then!

The design came back from the designer yesterday:

Its hardly ground-breaking stuff, but it does throw up some pertinent issues. Firstly the obvious deconfliction of adjacent projects. This has been a near constant issue, and one which has caused some contractual variations. Clearly the best way is to do it early. In this instance it can be seen that information about the location of utilities were made clear to the adjacent project, however in squeezing in a drainage run between so many utilities the adjacent project has been burned by, I guess ‘unforeseen ground conditions.’ (ie the ductbank wasn’t where they were expecting it to be). Second the fact that the client on my project has the requirement to harden utilities. I gather that it is far from standard practice, but concrete wrapping ductbanks in areas of high utility/ services congestion adds to the complexity of installation. Predominantly this is because of the space required, but also it takes much longer and costs a lot more. I’ve been able to make a large saving (I blogged about it earlier) by questioning the requirement to harden some of the less critical utilities here. There is also the question of maintenance? In any case, in this instance the client would not have given latitude to remove the requirement for hardening, and so the conflict will always have arisen. There is however a minimum level of cover to be observed on ductbanks when they are close to the surface. Perhaps if this was applied to those at a deeper level, as a sort of ‘fudge factor / buffer zone’ then the designer might have been constrained at an earlier time in the project and might have arrived at the culvert solution in the first instance.

Anywhere but Chatham…

Phase 1s,

Following up from Fran’s blog about Perth I thought it worth mentioning that there is a wealth of information in the blog archive about transitioning to phases 2 and 3. Looking back you will see that the blog has been a cathartic release for students past and present to whine about their experiences both overseas and when venturing out of the Army cocoon in the UK.

USACE:

https://htstrial.wordpress.com/2015/04/16/usace-not-a-place-in-china/

https://htstrial.wordpress.com/2012/03/23/progress/

Matt Fry had some difficult administrative times and is very articulate in presenting them!

BP:

https://htstrial.wordpress.com/2015/04/20/lang-time-nae-see-far-hiv-ye-been-min/

https://htstrial.wordpress.com/2014/04/21/getting-started-in-aberdeen/

For the design office to come:

https://htstrial.wordpress.com/2014/02/20/what-colour-is-my-parachute-or-do-i-have-add/

For anyone ending up in the US Brad and I have tried to ‘tag’ our posts so that they are a little more sortable. It may be something we could do in the future to separate the E&M blogs from the unending pictures of concrete too.

The blind leading the blind.

I have now started my design attachment in the USACE’s Baltimore District Headquarters and am currently working on two projects. One of which is a ‘server room’ cooling survey at Fort McNair in Washington DC, which this blog will focus on outlining.

I have realised my utility, I am cheap, and so have used this to secure some responsibility early. The project budget is $50,000 and, in the mechanical section, the average engineer’s time is billed at $135 per hour. The basic sum on this gives an engineer 370 hours, but add in project manager time, vehicles and other overheads and it can soon be eroded. This is something I will research into for a further blog but the upshot is that this is now my project, and a handsome little mess it looks like to. The scope of the work currently is to write a report on the cooling within a number of server and communication rooms within the Military District of Washington (MDW) office buildings. There are 15 different rooms spread across 8 buildings, built circa 1900, all with vastly different loads and in different conditions.

After meeting with the USACE project manager, the client and the HVAC engineer for the buildings, Don Ruhl (my partner from the mechanical section) and I toured a number of the rooms. As we travelled around it became apparent that not only did the client not know what they wanted; they also didn’t know what they had in the rooms. The photos give an idea of a couple of the rooms and the varying conditions.

Don inspecting the many unsealed penetrations in a small converted basement broom closet. This room had about 12U of switches and had a retrofitted ductless cooling system. It also had a condensate drain to a sump, thus allowing the condensate to re-evaporate and continually cycle through the cooling system.

Another basement room with abandoned hardwiring to the Pentagon. About 45U of high grade servers in here. The pipe on the floor is for chilled water with heavily damaged insulation allowing condensate to form on it in the summer.

Server rooms are ideally internal within a building in order to avoid solar heat gains and also because servers don’t need a window to stare forlornly out of. They are usually sealed from infiltration; tidy, to control airflow and have some form of HVAC. The current standard for low and medium density data centres and server rooms is to use a hot aisle, cold aisle system as illustrated below. Cold air is fed from low down in the ‘cold aisle’, either through the floor or by retrofitted ducts; the server blade draws it in through the front and rejects warm air through the rear into the ‘hot aisle’. This rises and is collected by the return air system. As the photos above indicate this was not the case.

So what. Well given the conditions in many of the rooms, even doing a complete survey would be incredibly costly on time. After this initial assessment we need to engage in some expectation management in what we will be able to provide and re-write the scope of our work, which is currently pretty open ended. I see this largely as focusing effort on the more important rooms in terms of upgrades and identifying the risks of each room to the client so that they can make an informed decision.

In an age of BIM, I have been told that the best we can get is a floor plan for some of the buildings so it appears that even a set of out of date as built drawings are a wish too far. Due to this if construction work is ever completed on this then the contract will almost certainly have to be a design and build as the potential for change orders on a traditional contract would be immense!

Finally, a little leadership challenge.

I mentioned earlier that I had been given the lead on this project but I am working with another engineer. Don has worked for USACE design section for at least 30 years and is probably the most intelligent person I have met out here. He has no aspirations of leadership and is very happy to let me control things; however his ability to take a tangent and dive too far into the details too early are something to behold. Certainly a different management challenge from both soldiers and contractors!

RE Wall Upstream Walkway and Piezometer Installation; A simple task…

The Reinforced Earth Wall (7.2 x 6.2 x 500m) that is currently being installed on top of the existing Earth & Rock-fill Dam also requires a small walkway on the upstream face. This is required to allow for the inspection of the settlement points as well for monitoring the RE wall itself (panel verticality/movement and for extracting the internal galvanised test straps).

DESIGN

METHOD

- Placement of stabilised sand (100mm). This was simply to provide a firm level surface for the L-Units to be placed upon as the large, angular 4B material produced an inconsistent surface level. It also allowed the temporary handrail to be secured in placed.

- Installation of temporary fall prevention system/ handrail.

- Backfill of rock armour on upstream face. Required to cover the stab-sand and improve aesthetics (..and durability)

- Installation of precast L-Units. (see photo 1). Originally, designed to be gabion baskets, these precast units were favoured for aesthetic reasons. The finish and uniformity of the units was flagged as being very low.

- Removal of temporary fall prevention system. (Design of fall restraint anchor required- see below)

- Core drilling of L-Units to allow piezometer conduit to pass.

- Piezometer marking/ protection.

- Installation of permanent handrail to top of L-Units.

- Backfill of precast concrete L-Units using large rock-fill material (Layer 1 (0.45m)). Agreed upon by SPE due to large cobble aggregate to be used (20 – 75mm).

- Installation of plastic electrical pits.

- Further placement and compaction of backfill material (Layer 2 (0.45m)).

- Installation of pavement formwork, steel reinforcement, jointing, end stops.

- Construction of concrete pavement (310 x 1.6 x 0.1m).

Point Loading the RE Wall. I assessed that the pumping of concrete from an unfinished RE Wall to a walkway 3m below was the greatest risk to this phase of construction. A 36m pump would be positioned onto the RE Wall crest in order to pump 12 x 6m slabs/ day. Each outrigger leg was rated up to 192 kN but with the walkway so close, it was assessed that this force was unlikely to be approached. Upon receiving the concrete pump technical data, it at first appeared as though we would not have sufficient space (See image below). Fortunately, this was not the case and it was able to safely operate simply using an alternative outrigger configuration. The important dimension was that of the 1.5m exclusion zone from the internal face of the RE Wall within which the outrigger could not encroach. This was likely due to the lack of frictional resistance offered by the steel strapping at such proximity to the RE Wall Face which prevents the vertical panels from pushing out.

Working at Height. Due to the steep upstream face, a temporary handrail was installed to provide a fall prevention system. Once the L-Units were in place the temporary handrail was to be removed. However, workers were required to wear harnesses for the removal of the handrail as it required them to step on the outside of the L-Units.

Due to the lack of fixing points, I was required to design a fall restraint system. M16 5.8 bolt was used with a small steel plate to provide an anchor point for harnesses. The simple anchor design required external verification before it could be signed off. A couple of hours later and the design was approved for immediate use.

Securing the L-Units. As part of the RECO L-Unit system, hot dip gal sheer keys are provided which meaure 1m in length. These slot vertically in between each concrete unit and ensure that the individual units operate as a continuous structure, whilst allowing a certain degree of movement. However, due to the subsequent placement and compaction of the cobble fill material between the RE Wall and the L-Units, I decided to pin them in place using 4 x steel rods as shown below. This was to prevent the units moving laterally away from the RE Wall as compaction occurred.

ISSUES

Piezometer Alignment. When initially setting out for the installation of the walkway, it soon became apparent that the piezometer alignment would conflict with the position of the precast concrete L-Units. Consequently, 100mm holes had to be drilled through the precast units to allow the piezometer conduit to pass through. As JH were also responsible for the location at which the piezometers rose vertically during prior groundworks (and before my arrival!) it was a simple matter that could have been avoided.

Missing Materials. Despite being fully assured by my predecessor that all components were correct and present I was a little under the moon to find out that approx. 10m of handrail fixings were not accounted for but an additional 30 vertical post were present… A swift call to the manufacturer and all was well.

5 x P’s!! – Poor planning lead to several avoidable issues during construction. ie. Precast L-Units requiring core drilling (5 x 100mm Ø holes) to allow for the Piezometers to pass up vertically to the surface of the walkway.

Precast Unit QA – Do not rely on consistent geometry of precast unit in planning.

Each of the precast L-Units has 2 x preinstalled ferrules. These provided a metric thread fixing point in precast concrete panels to which the permanent handrail will be installed. Due to the lack of conformity in the geometry of the precast units, the horizontal alignment of all the ferrules once all of the L-units was far from straight (even by Aussy standards). The final handrail would have looked terrible. As such the decision was made to drill and install new ferrules in order to achieve an aesthetically pleasing handrail alignment. See final alignment above.

Check and Double Check material quantities!!

Reo Bar Chairs – Ordered 1000 x 45mm plastic bar chairs to sit on the uneven 4B material. Thought to be too many but required more 75% way through bay construction. Underestimated spacing required due to uneven 4B material…

Bolts and Ferrules. To determine the bolt length that was required for a pre-installed ferrule which is not detailed on the drawings, do not simply measure the ferrule depth using a steel rod (who would do that?..). As the base of the ferrule is rounded, the depth that a bolt can actually penetrate is approx. 5-10mm less than the full ferrule depth. If a bolt then protrudes greater than required the handrail baseplate will be loose (apparently..).

OTHER NEWS..

New Chaffey Dam Site Office resident fancies a brew!

Oz PCH – Chatham to Perth

Introduction

Now that the Phase 1 students have been informed of their Phase 2 attachments I thought I’d blog about my (and my wife’s) experiences on initial move out here to Perth. I actually got my wife to write this after being here for a few months so it will not discuss any John Holland work related aspects. If anyone does actually end up in Perth on a John Holland project then I will be happy to discuss any specifics separately as the likelihood of working with some of the same people is very high – there is only one new project in Perth that John Holland are currently tendering for.

Despite being the second most isolated city in the world; after Honolulu, Perth really is a wonderful place that has something to offer for everyone no matter your interests or preferred life-style. We have had a wonderful time so far and thought some of the things we have learnt in this first month may be of use to others. Firstly, there are some things you can do from the UK that will make your trip that bit easier. The main one would be to organise an Australian bank account – we went with Commonwealth Bank [they have a very handy smartphone app and have lots of branches doted around]. This can be done from the UK and all you need to do when you get here is head into the nearest branch and finalise some details. Make sure you take your passport for this as UK driving licenses and Military ID are often not accepted. [All this information and more can be found in a PowerPoint presentation on the PEW SharePoint].

Travelling

You won’t have too much choice on airlines but you will be able to decide if you would like an overnight stop. It is important to remember that unless you have children you will have to pay for this out of your own pocket. [Qantas has announced a non-stop flight by 2017, see link below, but to be perfectly honest a few hours transfer in Singapore is no drama at all and I can recommend Singapore Airlines].

Weather

We arrived in autumn [March] and the weather was gorgeous. Locals grabbing for their coats but you won’t need anything more than a thin jumper in the evenings. [Hot enough to call it a British summer that’s for sure].

Initial Stay

We were put up in Quest Apartments for the first month. It is worth doing a little research before you leave so that you can suggest where you would like to be living; coast or city, dependant on distance from site of course. We were in Scarborough (on the coast) and although it was a little far from work [I wasn’t working for the first 3 weeks] it was a lovely vibrant place to stay with plenty of restaurants and a stone’s throw from the beach. These apartments provide a charge back service so that we could eat out and charge it back to our room where John Holland picked up the bill – very handy and definitely recommended.

Driving

Although the buses and trains are relatively good in Perth it is preferable that you have a car as things are quite spread out here. There is very minimal traffic on the roads even in rush hour but you do need to stick closely to the speed limits, which are significantly lower than in the UK (on avg 50 and 60 kph on main A-roads), as the police are very vigilant and like to set-up mobile speed cameras; camouflaged and hidden behind bushes not like the easily seen yellow boxes in the UK. Make sure that you check with the car hire company [Hertz in our case] that they have your correct arrival flight times (we were delayed slightly) so after the long journey over you have a car ready and waiting for you and don’t have to wait 45 mins like we did.

Parking

Although site specific, on-site parking is between AUD $20 – $25 (£10 – £13) per day, so cycling into work was preferred and made more enjoyable by the predictable sunny weather. Perth has some great cycling paths and on rainy days there are always the buses or trains that work well.

House Hunting

Finding a house was much harder than we thought. Our biggest issue was that 95% of rental properties out here are let as non-furnished. Back in the UK we thought furnished would be much easier – but be aware this dramatically limits availability. You need to weigh-up whether you think it’s more hassle to ship furniture over/buy some when you are here and use the Army buy-back scheme or spend longer looking for a fully furnished property. We have been persistent/lucky and stuck with looking for fully furnished and have found an awesome three bedroom house 8 min walk from the beach.

Finding Work [for the wife]

Being a teacher we thought it would be easy finding work; on the contrary, it was extremely difficult but mostly due to the education system here being set-up differently and there is definitely a clique of looking after their own first. Make sure that if your partner intends to work that they do extensive research into the requirements of that profession. Bring all your original qualification documents in case you have to send off copies to prospective employers as they will have to be officially certified. There are plenty of schools though just not that many jobs. Relief work, managed through an agency, is the best foot-in-the-door way to secure a full-time position.

Fitness

If you are into fitness [which you should all be] you will be spoilt for choice in Perth. We fully intend to try everything [and have had a good stab at most things so far] and have already fallen in love with stand-up paddle boarding. [Being a tri-athlete there are some great clubs in Perth, mine being Stadium Triathlon Club. This also extends to purely swimming (my wife is a member of Claremont Masters) and cycling clubs; which are all plentiful and very well attended. To that end, if you are a cyclist or think you might like to cycle out here, and I’d suggest you do as it’s a great way to explore Perth, then definitely ship your bike(s) over. Fitness is part of the culture out here and everyone goes to bed early so they can get up early for a pre-work session; massively helped by the utter rubbish that is on what they call TV. Even at the weekend you will see a lot of people up at 0600 walking dogs, running, cycling and swimming – it literally is a Mecca for sports!].

If anyone on attachment to Oz would like any more info please drop me an email franrizzuti@hotmail.com

State to State will vary somewhat for which it will be best chatting to the others out here once you know exactly where you’re going but any general questions are very welcome.

In Other News

This is what happens when a neighbour reverses onto your driveway to let another car past but accidently puts his foot on the accelerator instead of the brake!

Site Two Fifty One – A few examples of how things can be done.

Site Two Fifty One – A few examples of how things can be done.

This is just a quick blog with an update of where things are on site. If there is an area of interest I will expand/find out answers in the comments.

1. Kwika strip slab starters. As previously mentioned we would be using kwika strip in the walls. This shows how they look pre-pour. The bars have about 30 mm cover within the case.

2. Sky deck falsework. This is a Peri system which is quick to erect. It requires bracing using chains and a section of trusses to transfer 2.5% of the vertical load. We did not silicone between joints but used a plastic t-section. There was some grout loss down the faces of the walls and columns which was washed off to avoid disfigurement.

3. When can I strike? The next challenge was to know when the falsework could be struck. The method used is based on a crack width assumption that compares construction loads with unfactored service loads against the concrete strength (fcu) (see page 186 in ‘CS30 Formwork. A guide to good practice, third edition, 2012’ for full details). This slab is for a plant area so the ratio is low resulting in the concrete strength required to be 15N/mm2 to strike which should be achieved in 4-days. However, we will crush cubes daily and have thermocouples placed in the pour and cubes, so we will correlate to give an accurate actual concrete strength, which if reached earlier than 4-days will mean we strike the falsework sooner.

4. Concrete miss-match. Some of the building’s columns are 60N/mm2 whereas the B1 slab is only 40N/mm2. Therefore within the B1 slab pour a section of 50N/mm2 concrete was puddled around the column locations to avoid a miss-match in strength of more than 10N/mm2…

5. Column formwork. 2-sided formwork – props used to keep column vertical rather than taking significant horizontal load. The horizontal load is carried within the internal ties.

6. How do you build this? This is a sump 3.1m deep by 600mm . 600mm. To install any sort of formwork and then strike it would be too small a pit to put an operative in to work. Not necessarily the best solution but a quick one is to use precast sections (similar to manhole rings) to build up and pour the walls around it. The outer size of the chamber had to be increased but there was no spatial constraint to prevent this so hopefully the plan will work!