Thames Tideway Epic induction

Thames Tideway Epic induction

I attended the Thames Tideway Induction this week. Even if Carlsberg did health and safety inductions it would not be half as good as this was. It was simply Epic, which actually stands for Employee Project Induction Centre.

The Problem

The Tideway Project approach to Health and Safety is an attempt to re-set precedence where currently major projects (such as Olympics, Cross Rail, Heathrow) tend to have an increase in RIDDOR incidents at the start of a project (as new employees get bedded in) with a peak a few months in, then a decline to a plateau and a rising spike at the end (towards handover). I think this is pretty similar to operational accidents in theatre where there was a learning period which caused injuries, then lessons are learned but by the end there is some complacency resulting in a final spike.

Graph of RIDDOR incidents – representative only and recreated from induction slide – hence magnitude of numbers removed.

Using the accident numbers from previous projects against the number of hours planned to be worked on the Tideway project would mean:

- 2 deaths

- 1500 life changing injuries

- 10,000 lost working hours

Clearly you can’t accept that (or effectively plan to kill 2 people and injury 100s more) and so the whole push from even before starting is to set the standard at high in hope that will result in a better outcome.

The induction

Tideway have rented office space next to MI6 and have created a mock up accident scenario. I’ll be light on the details in case anyone else goes through it but effectively the day starts with you in the site canteen and 2 workers arrive (taking us, the audience, by surprise). They chat about random day to day stuff. They then leave to work on site (audience follows to site). There is then an accident of one of the workers who later dies (scenario, not real). The audience then moves to another room – HSE investigation which is pretty tough for the audience too, then the flat where the employee lived (heavy play on consequences of such an event), then a room split between a site office and a head office to hear background conversations leading up to the event. Back to the canteen (to recover) and start the practical training.

The day is run by a team of actors from the Active Training Team company who role play through the scenario but then are there to re-run the scenario to talk through what the causes were and what actions might have resulted in a different outcome. This is similar to the role play equality and diversity training the Army now do but far more interactive.

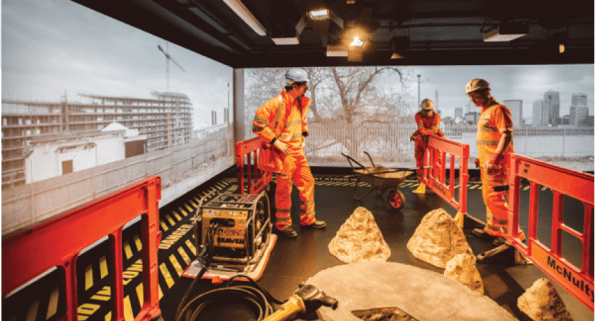

Scene from the induction centre – actors playing very convincing construction workers

The afternoon was filled with behaviour based learning – all practical group discussions which included at some stages going toe to toe with the actors on various other scenarios. The point being to learn techniques and methods for all levels of construction workers to improve their behaviour and mind-set towards health and safety.

Level of Engagement

There was one 15 minute presentation which was delivered by the CEO of Tideway (Andy Mitchell – recently on the front of NCE magazine for different reasons) of a £4bn project so it is clear where his focus is.

Methods

The health and safety approach is pretty impressive, especially if this is to be the standard that every employee (over 5000 expected) over 5 years goes through it. They have got a comprehensive approach covering worker language skills, issuing of the best PPE, lessons learned from Heathrow, Cross rail and the Olympics, 3-monthly stand downs across all sites to discuss H&S issues, and a drive to have the most secure sites with the best welfare facilities.

Will it work?

I think the recognition of the problem and desire and motivation to change history is fantastic. However the difficultly will be in getting everybody to embrace it when budgets are squeezed, timelines are reduced and concrete wagons are ready waiting on site. If the collection of parties play their roles well – designers design safe and buildable structures, contractors allow for safe working methods, invest in employee training and Tideway live up to the standards they are talking about then I see no reason why the injury levels cannot be reduced. I do not believe there is an argument for the irreducible minimum in this instance with money and time, quality (in health and safety) can be achieved.

Summary

It will be interesting to see how it plays out. There are some particularly hazardous working environments: underground, confined spaces, deep excavations and over water. The 3 sets of joint ventures (8 different contractors) will have a far more onerous task of getting people to acknowledge the risks and how to mitigate them. A balance between having to produce paperwork against the level of risk an activity possesses will have to be considered to make sure effort is best placed to achieve the desired effect. Finally, with this significant investment and change (improvement?) in mind-set to health and safety what happens if it does not work – are all major infrastructure projects doomed to kill and maim people. It is clear there is buy-in at the top and this is being pushed from the highest level so hopefully it will succeed.

Thanks for that Damian. It looks very impressive. I wonder if one of the challenges is not the list of hazardous environments you give in your summary (underground, confined spaces, deep excavations and over water) but the interfaces and seemingly trivial places: steps to a canteen that have inadequate side rails and get wet because of an uncleared gutter and so covered in ice first heavy freeze of the year result in a life changing fall down two steps. I often feel that the biggest risk areas have the clearest lines of responsibility and the easiest or most apparent means of raising and rectifying issues. Freuqently it is the small points, where to say anything is to be ‘always raising trivial issues’ and ‘fussing over nothing’ when the big risks are… and so the small risk becomes and issue. Without any evidence to back it I suggest that this is one contributor to the ‘irreducible minimum’. I wonder if the data has been crunched to see where the deaths and injuries occur in terms of time of day, time of shift, location on site and stage of progress on the sub task because begginning meiddle and end of a large project do not represent the same thing for most construction workers engaged on site.

Damian,

What accident / incident data triangle was used to generate the possibility of incurring two deaths? Is it construction industry wide, therefore including smaller “more dangerous” contractors, that makes things look worse than they actually would be?

What I find interesting is that you are in the design side and are being inducted in this manner. It occurs to me that there are elements in the constrction of a tunnel that are tricky and therefore finding of and management of risk demands that the design team are clear on how the project is likely to be executed.

Human factors play in here, of course, but it the designer challenge to try to ensure that the risks you can design out are designed out. You are unlikey to be able to influence behaviour beyond ensuring that there is an clearly understood execution method and that the risks you envisage in the method are properly communicated.

The constant reminder for constructors to ‘do it by the book’ is a day-to-day project management challenge.

Richard – Very much agree. A tale from site was that we placed significant effort on adhering to lifting operations standards and procedures but initially did not consider the slinger having to climb onto the back of a lorry to sling the load – probably the most likely point of injury. Taking risk as probability multiplied by consequence that would imply many of the ‘slips, trips and fall’ type issues are deemed low-low or low-medium risk so require minimal mitigation (perhaps a sign). Compared to the ‘big’ risks with high consequence grading. Although the example you cite is a good one with a high consequence. Regarding the statistics I think data is pretty generalised for all sub-tasks into a simple duration versus accident without the details behind who, how and where.

Rich – I don’t have the breakdown but expect it would have to have been on notifiable projects under CDM. Now that will be slightly different, in fact these figures were based on 3-day RIDDOR events, rather than the 7-day lost time now being the case. But even with major projects it does not take many deaths to soon amount to an equivalent ‘death’ prediction. I saw this week another worker on a road project killed, I know of at least 1 on cross rail and I think 1 on Heathrow. The fact that the Tideway project is something like a 6-year duration, you soon get to the number 2. I am almost surprised it is not higher.

John – I appreciate your final point. I was overhearing about a berm being used as temporary works to a retaining wall. On attendance to site it appeared some of the berm had been removed. I am fairly sure there was commuication of the risks associated with it but it can be hard to enforce or manage!