Archive

Paradise Circus, Birmingham

Welcome to Paradise

On the 22 February I started work with Carillion PLC on the Paradise Circus Demolition/Construction in Birmingham.

The development scheme involves the transformation of 17 acres at Paradise Circus in the heart of the city centre. The £500m development is being brought forward through the joint venture company, Paradise Circus Limited Partnership (PCLP), a partnership between Birmingham City Council (BCC) and BT Pension Scheme, managed by Hermes Real Estate with Argent as development manager. In addition to the developer other interested parties include Amey who maintain the A38 Queensway Tunnel on behalf of BCC.

The project is currently in the Phase 1; primarily demolition of the RC concrete structure of Library and office buildings. Phase 1 also includes some large bore piling, up to 1200mm and the construction of a podium deck car park. This will be the platform for future development (contracts that Carillion are highly competitive for at the moment, but have not been awarded). The future development aims to bring over 300,000 sq ft of grade “A” office space to Birmingham City Centre.

Demolition of the main building, the reference library, is primarily being completed through use of a high-reach excavator. This plant weighs in excess of 1600kN with the potential to put a very large point load on the ground beneath.

I have been tasked with the monitoring of the A38 (Queensway bypass) that passes under the site through a combination “cut and cover” and bored tunnel. The majority of the tunnel has a precast pre-stressed inverted T-beam roof. These are infilled with concrete and laid edge to edge.

There is a concern that the high-reach excavator is too heavy to use in proximity to the tunnel. To mitigate the risk of the plant load, the site has been divided in to zones 1-4. Zone 4 not requiring a specific RA for the tunnel, down to Zone 1 which needs a full RAMS and approval from the BCC Engineers. Zone 1 is above the tunnel or within a 45 degree angle from the base of the tunnel.

Trigger levels have been set by theoretical modelling of the tunnel. Remaining capacity of the T-beams is calculated and the Red trigger level is set around 80% of the ULS (evidence of this is assessment is elusive). Monitoring has been installed in the tunnel and the normal deflection pattern established (this is over a 2 week period, but I cannot seem to find any evidence or analysis of this). Interestingly – or not – the normal pattern of life seems to move the tunnel through twice the deflection that has been set as the Red trigger level. This has resulted in the Section manager and project director receiving upwards of 300 alerts last week alone (I haven’t received my work phone yet so I’m dodging that bullet at the moment). The tunnel hasn’t collapsed…yet.

A load test is being conducted on the inverted T-beams to test the theoretical model. Type 1 Aggregate is compacted in layers over the course of 4 days. The first three days, 2 layers are compacted with two layers of 150mm compacted on day 4. Each morning a materials technician from Environmental Services Group (ESG) carries out a Nuclear Density Test on the aggregate to ensure the sub-contractor has reached 90% compaction density.

The final layer of aggregate is currently being placed by the sub-contractor. The senior engineer and I are responsible for checking the levels of the beam – currently we have 0.5mm deflection throughout. This is done through a series of 3m rebar pins that have been set in concrete on the roof of the tunnel (as well as the automatic monitoring inside the tunnel).

I am still trying to get my head around the expected outcomes and controls that have been applied to this test. It seems to me that the trigger levels have been set too low and the equipment monitoring the deflection in the tunnels are not that accurate (influences such as temperature, traffic flow and pollution can impact the results).

I will add an update when the test is complete and we have the results interrogated.

Oz NDY – CPD Activities

Australian SAS Operator

Introduction

In similar fashion to the comments on Riche’s latest CPD blog, I too have been hunting out more formalised CPD activity opportunities. Although there are some within the design office I wanted to broaden my search and so started looking for opportunities outside of the workplace. Namely seminars, conferences and workshops delivered by professionals in the building services sector and that are affiliated to various engineering institutions.

This blog briefly discusses a seminar I attended hosted by Lighting Options Australia as part of the Society of Building Services Engineers WA Chapter in association with CIBSE.

Lighting Options Presentation

The seminar consisted of the usual finger food and drinks reception, with a studio tour followed by a technical presentation on LEDs in 2016, which culminated in a Q & A session.

The speaker, co-founder and MD of Lighting Options Australia has been involved in lighting throughout his 17 year working career, combining on-the-job experience and knowledge whilst working in partnership with several internationally renowned lighting brands.

Before the presentation kicked-off the speaker demonstrated some of the lighting options used in their showroom gallery. One painting of interest was the Australian SAS Operator, which was painted by an ex-serviceman’s wife. It is said that whichever angle you look at it from, it always looks as though he is aiming directly at you.

The presentation covered three areas:

- LED performance in 2016.

- LED/Luminaire life and lumen maintenance.

- Introduction to Richard Kelly’s ‘Language of Light’.

Presentation Summary

- LED performance in 2016. Four factors were discussed: efficacy, colour tolerance, colour rendering index and failure rate.

- Efficacy. Luminous Efficacy is the measure of how well a light source produces visible light (to the naked eye). It is the lumen value against the energy consumption, measured in Lm/W. Manufacturers usually display this technical data along with the colour temperature, measured in Kelvin (K). For example, 100 Lm/W (3000K) or 130 Lm/W (4000K). The colour temperature describes the impact of colour, which gives either a warm light (<4000K) or a cold light (>4000K).

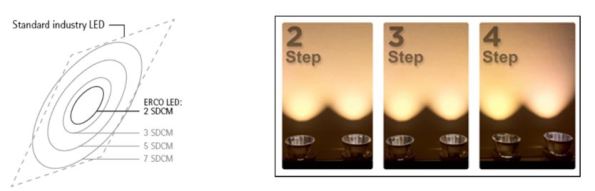

- Colour Tolerance. This is the colour consistency amongst exact same light sources, for example, an array of lights along an art gallery wall, where a higher colour variance in one source could be very noticeable and detract from the required lighting effect. There is a standard/tolerance for the acceptable degree of variation in colour temperature, ANSI specification C78.377-2008. The tolerances can be identified by applying the MacAdam Ellipses. The size of the ellipses is based on the standard variance called ‘steps’, the more steps the higher the variance and more obvious to the naked eye (see figure 1).

Figure 1. Colour Tolerance measured in MacAdam Steps

With the innovation of LEDs moving lighting technology away from the more traditional incandescent or compact fluorescent light sources, it introduces more variables where the Correlated Colour Temperature (CCT) of LEDs is liable to move further away from the target colour. Typically, incandescent and fluorescent ellipses don’t exceed 7 steps. Therefore, due to the easier identified colour variance, the LED standard states that CCTs must be within 4 steps MacAdam. The following link explains colour tolerance in more detail and is the source of reference.

http://www.lampslighting.co.uk/colour-tolerances/

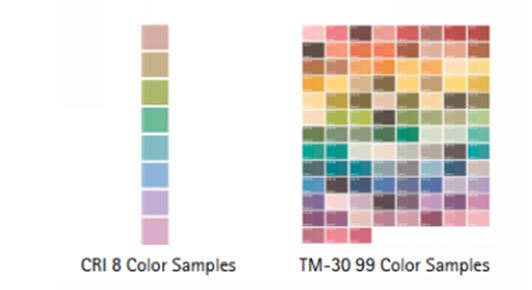

- Colour Rendering Index. Colour rendering measures the light source’s ability to render colours correctly and is graded from 0-100. The old standard was to use eight colours to act as the controls against a pre-defined light source. This has now been increased to a 99 colour sample (see figure 2). The new sample range is more representative of real-world objects as opposed to the original and is intended to fairly and accurately characterise LED and legacy light sources.

Figure 2. Colour Rendering Index.

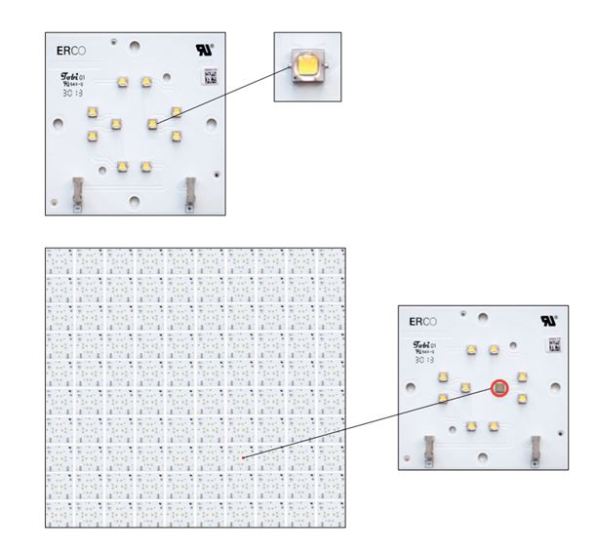

Failure Rate. When conducting lighting design and planning off failure rates it is important to understand that traditional, incandescent and fluorescent, light sources are failure rated at 50% over their rated life, which indicate that the lamp has failed to the point of needing replacement. However, the standard failure rate in the LED market is 0.2% for 1,000hrs. That works out as 10% after 50,000hrs (the standard LED manufacturer specification failure rate which is extrapolated from an industry accepted standard of 8,000hrs burn time). The latest in LED technology, as manufactured by ERCO, has decreased this by 100 times to <0.1% for 50,000hrs. By example this means if using 100 x 10 LED chip luminaires in a project then only one single LED out of 1000 might fail after 50,000hrs.

Figure 3. ERCO LED Failure Rate

2. LED/Luminaire life and lumen maintenance.

This part of the presentation discussed the characteristics that determine LED life and maintenance. There are four values:

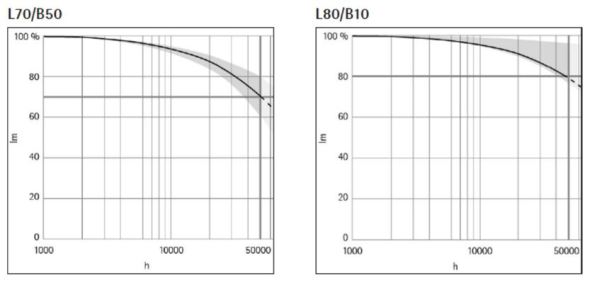

- L – This is the light output of a LED module which decreases over its lifetime. L70 means the LED module will give 70% of its initial luminous flux. This value is always related to the number of operation testing hours (usually 8,000) and therefore is a statistical value so a batch of LED modules may have a slight variance in their lumen maintenance. A point to note is manufacturers should state the testing hours of their product as some try and mislead their customers by only testing to 4,000hrs. This means there is likely to be a higher percentage of error when extrapolating to the 50,000hrs rated life but they clearly do this as it halves their testing time to approx. 5.5 months thus cheaper to produce and get to market. If a product doesn’t say it’s testing hours it is safe to assume it is 4,000 and not 8,000hrs

- B – This is the degradation value of LED modules which are below the specific L values. So, L70 B10 means 10% of the LED modules are below 70% of the initial luminous flux.

- C – This is the value of fatal LED module failures, indicating the percentage of modules that will actually fail.

- F – This is the combination of B and C values, for example, L70 F10 means 10% of the LED modules may fail or be below 70% of the initial luminous flux. As a rule of thumb the most commonly used values are L and B. The LED market standard specification currently used is L70 B50 (50,000hrs), e.g. after 50,000hrs only 50% of the LEDs used still achieve 70% of their original luminous flux. ERCO uses LEDs with the specification L80 B10 (50,000hrs), e.g. after 50,000hrs at least 90% of the LEDs still active achieve 80% of their original luminous flux. Figure 4 shows the two graphs for comparison.

Figure 4. Traditional Vs ERCO LED Specification Maintenance/Failure Rate

Here’s the difference in a real life example:

There are 10 x LED downlights used to achieve an average 500 lx and rated at L70 B50 (50,000hrs).

At 50,000hrs – 500 lx x 0.7 = 350 lx

At 50,000hrs – 350 lx x 0.5 (worst case) = 175 lx

The same 10 x LED downlights are used to achieve an average 500 lx but this time rated at L80 B10 (50,000hrs).

At 50,000hrs – 500 lx x 0.8 = 400 lx

At 50,000hrs – 400 lx x 0.9 (worst case) = 360 lx

So you can see using the L80 B10 specification retains 72% of the original lux level after 50,000hrs versus just 35% if using L70 B50.

3. Introduction to Richard Kelly’s ‘Language of Light’. The final part talked about the American lighting designer, Richard Kelly, who was said to have been one of the pioneers in architectural lighting design. One of his goals was to be able to get both architects and lighting design engineers to speak the same ‘language of light’. To achieve this he came up with a very basic concept that broke light down in to three simple elements:

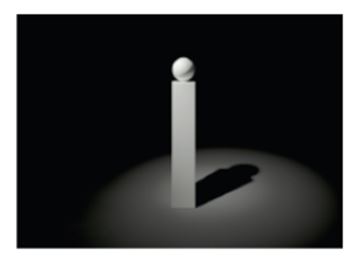

- Ambient – ‘Ambient luminescence’ is the element of light that provides general illumination, ensuring the surrounding space, its objects and any people in it are visible. This form of lighting facilitates general orientation and activity. Ambient luminescence is the foundation for a more comprehensive lighting design and aims to have differentiated lighting that builds upon base layers of ambient light.

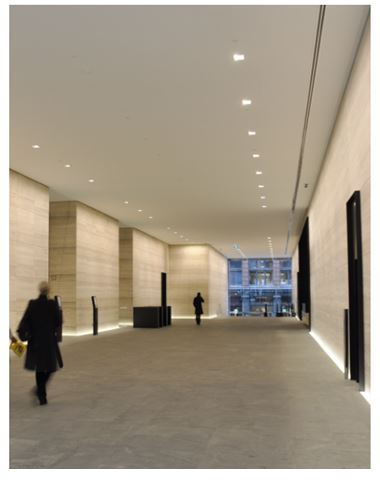

Ambient

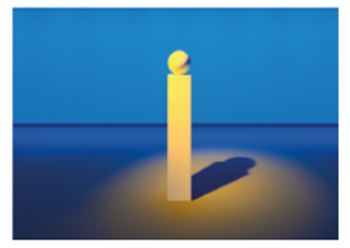

2. Accent – ‘Focal glow’ is the light that helps to convey information and guide movement. Brightly lit areas automatically draw our attention. Directed light accentuates focal points and helps to establish a hierarchy of perception using brightness and contrast, helping to emphasis important areas and accelerate spatial orientation.

Accent

3. Scenic – ‘Play of brilliants’ results from the ability of light to represent information in and of itself. It covers a multitude of lighting effects used for their own sake, for atmospheric or decorative reasons, but having no specific practical function. Examples include, an emotive candle on a table, a fire place, an object of coloured light being used to influence the ‘climate’ of a space.

Scenic

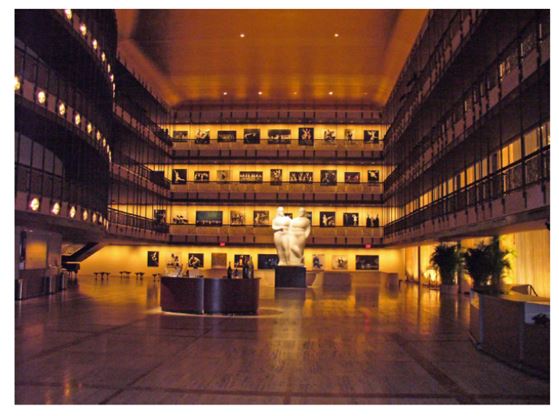

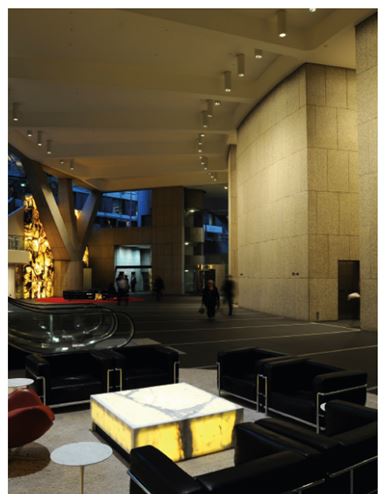

Examples of all three elements combined can be seen in the following photos:

The State Theatre, New York

Grovsvenor Place, Sydney

171 Collins Street, Melbourne

Forthcoming Events

Having chatted to the CIBSE Fellow who organised the event I am now in his ‘in-tray’ for any upcoming events which he assured me are roughly one per month covering various building services topics.

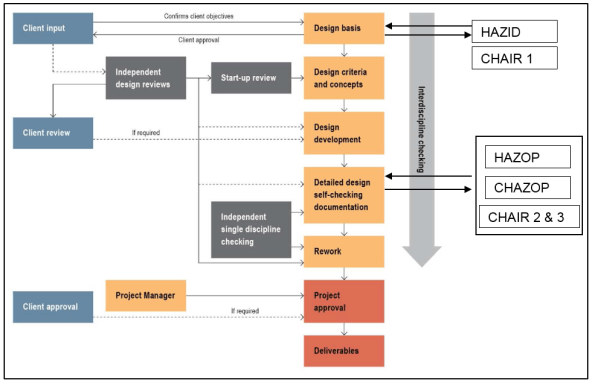

Safety in Design

Since arriving at KBR I have been involved in various elements of Safety in Design (SID). I don’t recall the subject being touched on in great detail on Phase 1, but it forms part of the core business of the design team. This blog gives at introduction to the systems used by KBR and some of the key issues I have witnessed so far. The basic steps in the KBR SID process are covered below, how the fit into the design process is illustrated in Fig 1.

Hazard Identification (HAZID) studies are generally conducted at an early stage in the design by senior designer and the client. Identifying key hazards early means that they are revealed before significant costs have been occurred in the design process. It also means that if they are unavoidable further risk reduction measures are actioned during the detailed design.

Construction Hazard Assessment Implication Review (CHAIR) is a tool to assist designers, constructors, clients and other key stakeholders to come together to reduce construction, maintenance and demolition safety risks associated with a design. The design can be considered as a whole or sub systems. Generic guidewords are used to identify hazards associated with three stages of a project; concept, construction (also including demolition) and maintenance and repair.

Hazard and Operability (HAZOP) studies are carried out as the detailed design is beginning to go firm. It is a detailed hazard and operability problem identification process, carried out by a team generally including representation from the client, operators/maintainers, suppliers, designers and installers. The design is broken down into ‘nodes’ related to how the system is designed to operate. Then various guidewords are used to provide out of normal operation scenarios. For each one the risk, cause and consequence are recorded, along with a solution if agreed or an action.

Control Hazard and Operability (CHAZOP) studies are carried out once the control narrative is complete. Similar to the HAZOP the CHAZOP study uses a number of guidewords to study deviations from design intent caused by computer/control issues.

Although this looks like a very linear progression in reality it is very iterative with the feedback from various stages been integrated and reviewed before the next. All of these processes are recorded and form part of a SID report for each project. This then provides a log of how a design developed and why decisions were made. It forms a key piece of evidence should something go wrong with a plant in the future.

Fig 1 – The Design and SID Process

So far I have facilitated a couple of HAZOP and CHAIR meetings already and taken part into a few more. Some of the issues I have picked up so far include:

- The importance of the leader – the lead of the workshop is a key role. They need to keep the group on track, ensure all key information is recorded and prevent discussion going down various potential rabbit holes.

- Time Management – The key to the meetings is to identify hazards not solve them. Should a point take more than the allotted ten minutes it needs to be reviewed separately.

- Time Allocation – The workshop needs to have sufficient time allowance and should be broken up if possible. Generally the sessions I have been to have lasted all day and the level of interest thus the quality of the output drops throughout the day. Sequencing to allow the high risks elements first can also assist with this, as do sugary snacks.

- Design Quality – The design needs to be of sufficient quality and detail to allow the workshop to take place, otherwise it’s a waste of everyone’s time.

- Preparation – The designs need to be sent out in ample time for everyone to review and submit comments prior to the workshop – otherwise you risk the workshop disintegrating into a design review.

- Attendance – Make sure the correct number of people are present. Too many and the discussions take too long, two few or the wrong attendance and key items could be missed.

- Variations – Often this is the first time the client has looked at the design in detail and from my experience so far they try to use the opportunity to add things to the design. As mentioned previously the purpose of these workshops is to identify potential hazards, not work out who is commercially responsible.

CCB – Ft LEE Training Facility

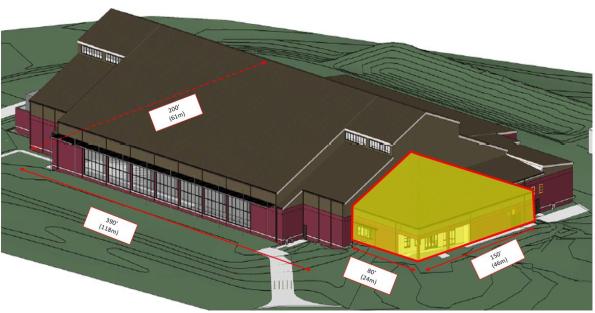

The ‘museum’ is still behind schedule. 95% submission is due mid – late march, a 3 month delay on the original. A rendering of the building is below, with my portion of responsibility shaded.

Ft Lee Training Facility

The larger space is largely progressed however the shaded portion, which is structurally separate, had not been looked at, other than producing a column grid and an interior plan. The promoter intends the space to be open plan admin and teaching space. Therefore a rigid frame layout is required instead of braced. This is comprised of lateral and gravity beams and columns, (with the latter being pinned at the ends, hence not transferring moment). I designed the frame keeping the lateral frames symmetrical as much as possible to reduce torsional effects induced by any wind or seismic loading. If there is not enough rigidity in the structure after running the seismic calculations I have enough ‘spare’ gravity columns which I can make into lateral columns to stiffen up the frame and retain some symmetry.

Structural Frame Design

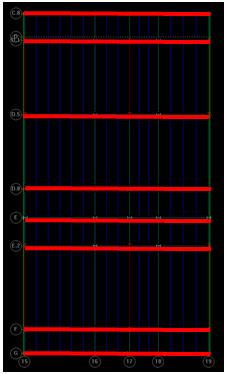

The loading of the structure has been affected by the Protective Design Center (Sic) (PDC) who have said that the cold formed steel truss system proposed for the roof doesn’t meet blast requirements. This is strange because stud walls and metal decks, which also consist of cold formed steel, are adequate systems. To me this means that either they haven’t been able to test the particular roof truss system in question, or there is an issue with the truss connections. The roof system is ‘designed by others’ so options were to either specify a requirement for hot rolled angles to form the roof truss or provide a second roof. The first option would greatly increase the weight of the roof and affect seismic design as well as costs whilst the second (selected) requires joists and decking. That means that the load paths need to be considered and modelled appropriately. Instead of having the ‘high roof’ which will transfer the wind and snow loads into the frame, sitting across the joists it will sit directly onto the main frame. Modelling roof loading across the flat roof decking would incorrectly increase the joist size and would increase the costs unnecessarily. I will therefore model the ‘high roof’ loading as line loads running across the beam lines as shown below.

High Roof Loading Model

I will input the permanent and variable loads for the roof based on the relevant standards (in the same way as we get our values form the ECs) but I will also need to manually calculate and input the snow drift loads. These, along with the seismic loads have not been calculated for my portion of the building so I am grabbing as many design examples, codes and text books as I can, to handrail. The computer will automatically model the wind and seismic loading which I can cross reference with hand calcs.

Environmentally the site as a whole is legally required to maintain similar conditions to the pre-construction water run off conditions, in line with the Energy Independence and Security Act 07 (EISA 07). This ‘low impact development’ (LID) approach is managed by the civils (site development) department who will design in methods to ensure the targets are met. These targets will be set by the initial site assessment which will look at things such as hazmat risks (POL), asbestos water quality and quantity of run off.

The promoter will budget the costs of the designed measures (swales, pervious parking areas, filter strips, and vegetated buffers etc) which are required to maintain the site at or close to its pre-construction state. The estimated costs are entered as a separate line item on the form that is required to request project funds from congress and are based on 2% of the overall ‘supporting facilities’ cost. This policy is intended to ensure that all government projects have adequate funds available to cover any LID requirements. ‘Supporting facilities’ are anything that isn’t the constructed asset itself and includes such things as the electric, gas and sewer service costs, pavements, storm drains, ATFP and any other site improvement / demo costs. For this project the ‘supporting facilities costs are estimated to be $5.5 million, therefore implementing the LID measures has $110,000 budgeted. This will presumably form one of the constraints on the design. To me the figure feels low considering some of the effort that is required to treat water before it is discharged from site in line with EISA 07, however this line item will be added to all the others for the project and a 5% contingency added to it.

Building 8607 Renovation, Ft Meade. The Design Build RFP (aka ITT) sections are produced by the different departments in the Engineering Branch. I helped the costing effort by producing a rough schedule of quantities expected in the ATFP upgrades. I based this on drawings which were used in the upgrade of a similar project which used the alternate path method of hanging floors using tension rods in the event of a column removal.

With the odd exception most values required by the estimating department were in tonnes, so fixtures and fittings (bolts etc) had to be converted from individual units. Other bits of work, for example welding or demolition of walls, was required in linear or square feet. I was a bit stumped by how I should tackle the installation of the lift but was advised that a line saying ‘1 x lift’ was sufficient! Whilst I was happy enough with that it occurred to me that it would probably be a bit of a waste of time for me to do that because there are people who are much better placed to do it. My value came in understanding the structural components of the ATFP system and being able to dig into the weeds of that. The selected ‘preferred’ ATFP method has been based on the fact that it has been done before, and that is what has dictated the government estimate. However, the contractor may well decide to completely re-build the concrete framing and install a tie force method of ATFP while he’s at it. This could potentially mean that the government estimate is a long way off the contractor estimate which, if realised, will introduce a bit of risk into the tender process because it will increase the complexity, hence increase the duration, of the negotiation process. Having said that we had to start somewhere and using precedent seems as good a place as any in this instance.

Access Control Point, Ft Meade – This project is now due to start in July 16.

CPD

One of the competencies I was aware that I was weak on prior to turning up at phase 3 was E4 – CPD. It’s not that I hadn’t done any CPD during phase 2; I’d done a reasonable amount through blogging, conducting Carillion online training packages, weekly informal educational periods with my mentor and reading journals. What I didn’t feel I’d done well enough was attend formal events; simply I found the pace of life during phase 2 too hectic to achieve what I wanted to.

During the three months I have been at phase 3 I have already managed to attend 4 formal CPD events. And have got more pencilled in, which I feel will be more than enough to cover off my requirements for professional review. The next stage will be to make sure they are all formally recorded. Although I am finding phase 3 a lot more stable than phase 2, I’m still finding it difficult to attend evening CPD events. I’ve found trying to strike the balance of doing CPD in the evening, army evening work, family life and social commitments difficult. Time is my critical resource, things slip and often evening CPD events have to drop off the radar. I am lucky that my current employer if fully supportive and arranges for companies to come in and deliver CPD on a regular basis during the day which is helping, however, a resource that I haven’t utilised enough previously and am starting to do more of are webinars. Many of these webinars are accredited to institutions and there produce certificates that making recording them formally even easier. A few that I’ve come across so far are:

Colt – Ventilation, smoke management

BSRIA – various

https://www.bsria.co.uk/information-membership/events/webinars/

British Safety Council – Upcoming event with regards to environmental standards

https://www.britsafe.org/events/2016-webinars

CCB – MPD at the Pentagon

Me and Henry got swept up last week in the Baltimore Military Professional Development visit, part of which was to the Pentagon to see a failed project. This portion only lasted a short while so I don’t know all the the ins and outs, but it was interesting none the less and raised some interesting points.

The project itself is to upgrade a goods and service entry point to the Pentagon, and is one of the final upgrades required for the whole site. It’s a job worth a relatively small figure but is fairly high on the Pentagon list of priorities. It was procured on a traditional contract and awarded to what is called an 8A contractor. That is, it was awarded to a smaller ‘disadvantaged’ company in line with the government social sustainability responsibilities. To qualify as a smaller company doesn’t necessarily mean it’s a ‘pikey’ outfit with a white van for a head office, and the company that won the award employs c. 500 personnel. It must also have a history of successful contracts which it will have submitted as part of its tender. As mentioned the contract was terminated by the government for non performance. It seemed that the contractor felt that it couldn’t complete the awarded contract due to the amount of variations it was presented with when it arrived on site. Apparently some of the SI was incomplete and there were a number of underground utilities which were encountered unexpectedly. This seemed strange given that to a contractor variation typically means additional money? Especially on government contracts where I’ve been told that some of the larger principal contractors have a reputation of tendering for work with the aim of tying the government contracts in knots (driving a bus through) and making small fortunes. One theory I can think of is that in adhering to government requirements there are certain administrative obligations placed on contractors. If the contractor was not used to this, which implies a lack of rigour at the contractor selection board, then perhaps it was not especially well set up to comply. This could potentially mean that payments (or a percentage of them) for work were held back by the government. This would affect the contractor cashflow and may have had the opposite effect to that intended. (ie demotivated the contractor)

The contract duration was around 12 months, however in 12 months all that had been installed was some signage and fencing and 4 manholes with connecting runs. Certainly not the progress I’d expect from a competent contractor this hints at a level of ineptitude or lack of direction. At present the Pentagon is demanding of USACE a resolution, which USACE is currently administering. The bonds will be cashed in and go towards paying the contract sum lost for payment of work to date. This will draw a line under the old contractor’s responsibilities under contract which will probably be novated to another principal contractor. The whys and wherefores are probably more interesting the deeper you dig, however because the case is current the guide was very tight lipped. What struck me was the risk that the government takes on in discharging its social sustainability responsibility, particularly on a project at the Pentagon, and the seemingly missed opportunity by the ‘disadvantaged’ contractor which will now likely never win another government job in its future

If Carlsberg did risk mitigation for piling

Bank Street – If Carlsberg did risk mitigation for piling

I attended a site visit to Bank Street at Canary Wharf this week. Arup are the design engineers and Laing O’Rourke (Expanded Piling) are doing the piling. The activities are mainly piling so far there have been an incredible amount of problems, solutions and wonderings to be discussed. I’ve attempted to highlight some here.

The current site – note central CHS piles for reference later.

CFA piling

Test pile

The plan was to install the tension piles for the main test pile but the rig being used could not extract the auger once it had reached toe level. The issue was found to be that as the top of the auger went below ground level the material on top of it tended to pack it in on top so trying to extract resulted in the mass of soil above the top of the auger being too great to remove. Therefore a longer auger, one that extended the full pile length was needed, and an equivalently long mast. This was realised and a new rig was used with success.

As part of the specification each pile installation was checked for the rate penetration with auger rotation. The aim being to get 10 rotations per metre. This reduces any flighting where soil material is dragged into the pile and therefore reduces the pile diameter. This worked well and the rig can be automatic to achieve this.

Example of getting the flighting penetration rate too slow or too fast.

Instrumentation calibration

This is not something I really picked up on while on site Two Fifty One but is really important, especially with CFA piling as one can’t look inside the casing to check the base.

Pressure gauge – CFA piling relies upon positive pressures when filling the pile as the auger is extracted. The positive pressure implies that the concrete is being distributed all around the bore to construct the pile. The rig on this site read 0.5bar so seemingly all was well. However, something was amiss – When it came to inserting cages they only went a few metres until it was found the pile had collapsed in. The strokes on concrete pump were counted to ensure the correct volume was being distributed into a 2metre cubed box. It wasn’t so a pressure gauge test was done on the rig sensor and it was found to be faulty. The pile was being under fed by about 20%!

After the many weeks of trying to get these piles sorted for the pile test, the rig (new one) and old rig instrumentation was mended. My advice, or what I would do now I know it, would be to ask to see some of this calibration going on if I were on site while piling is going on. Arup put these tests in their specifications to ensure everything is working which seems sensible.

Cased, rotary bored piles

Secant wall

CFA rig with Secant wall behind.

Ground anchors along length of secant wall. Note which piles the anchors are in (female…?)

The secant wall was due to carry both horizontal and vertical loads. It was base grouted which is where the stiffness below the pile is improved, not ultimate bearing resistance, to reduce initial settlement. This is where the pile cures and sometime later the steel tubing inserted inside the cage is pressurised with water which cracks the bottom of the pile. [I have a photo on the way, but for now imagine a steel hose pipe running down to the bottom of the cast pile with a couple of holes in the bottom.] Grout is then pressurised inside the tube and in theory fills any voids around the base. A subsidiary check is to get a pressure to show that the grout is not just heading off somewhere. There should also be some pile uplift to prove base resistance. This was not always achieved which in theory would be a concern. But it was a secant wall so if uplift was achieved, would the piles have actually have been connected? The stratigraphy at the site is such that it is not far from ground to Thanet sands so working loads can’t all be taken in the shaft. Therefore it’s more important to understand about base resistance. One might question the point of doing a test with secant piles, other than with the confidence of reaching a certain pressure.

As a quick tangent, my colleague who worked on Cross rail, where penetration grouting was used, advised on the need to avoid over pressurising the base of piles because of the risk of heave. They only had 7m of soil above the base of the pile, let’s say 140kPa. 1 bar is 100kPa. Apparently you need 4bar to get the grout into the voids. Mmm turns out there was some heave!

Back to the site visit.

Double skin sheet pile wall

This was where the most fun occurred. 2 rows of sheet piles were installed to act as a self-supporting wall on one edge of the site.

![16838273893_3262acd6e2_o[1]](https://pewpetblog.com/wp-content/uploads/2016/02/16838273893_3262acd6e2_o1.jpg?w=595)

Near: Double sheet pile wall. This is filled with material then ties are placed and then the top section was concreted. Rear: Secant wall installed, reinforcement for capping beam can be seen.

Double wall cofferdam from the inside

The sheets were installed by pre-augering. Angela raised this as a question last year I think. Arup advised against it. As that was what the contractor wanted to do, Arup specified some come penetration tests either side of the piles to see what resistances were gained (minimum of 15 N value). A chart was presented down to the Thanet sands showing almost no resistance! The augering inside the piles had removed lots of soil and where it had influenced outside, it had reduced the soil strength to close to zero.

So what? The solution was to fill inside with concrete and grout the outside. Concrete was used to avoid having to go back and certify (if granular material was used it would probably have been difficult to achieve any compaction and may have failed further CPT tests, using concrete avoided that). This took months, was expensive and difficult to do underwater. Any plans to reuse the sheets anywhere below ground level are now out!

Summary

Firstly it was great to be back on site and see some piling elsewhere compared to Two Fifty One. The engineer had clearly been busy resolving problems but it seemed to be that most of the tests, checks and procedures were all sensible and go some way to mitigating what is really a pretty uncertain activity. One assumes all is well with the pile but really we have no idea. There is a balance between equipment, instrumentation and people. They kind of all need to chime together to reduce the risks. I feel that this visit was very useful confirmation of the sort of standards expected when piling in quite a range of issues.

More photos

Vibrating head with circular hollow section to push reinforcement cage to pile cut off level. We used a similar method at Two Fifty One, but without the vibrating head – this methods looks far easier but needs more equipment.

![20151111_DSC_0016_resize[1]](https://pewpetblog.com/wp-content/uploads/2016/02/20151111_dsc_0016_resize1.jpg?w=322&h=429)

The site before dewatering. Left: double sided cofferdam, centre: CHS piles shown above for orientation, right secant wall.

On the way in we saw piling under bentonite. Rig with digging bucket attached removing spoil. Bentonite silos (black), green objects in front are the cleaning chambers to remove granular material residues.

NLE Project Introduction

I started on Monday this week on the Northern Line Extension (NLE) at the Battersea Site. The project is a JV between Laing O’Rourke and Ferrovial Agroman known as (FLo).

The project client is London Underground (LU) tho

ugh the extension and stations are heavily integrated into the whole regeneration of the area. So Battersea Development (who are part funding the NLE along with 41 other developers) are leaning quite heavily on London Underground. Phase 3 of the Battersea development will sits on top of the station box. A big change to the structure caused a change to the design of the station which has resulted in an 8 month delay, and the design for the station is still being finished. Regardless, the political pressure (Boris Johnson’s office) would still like the development to be finished for 2020. I believe the commercial teams are still debating who will pay for this. The change to the structure caused the design to be changed delaying and extending the project length.

The Project

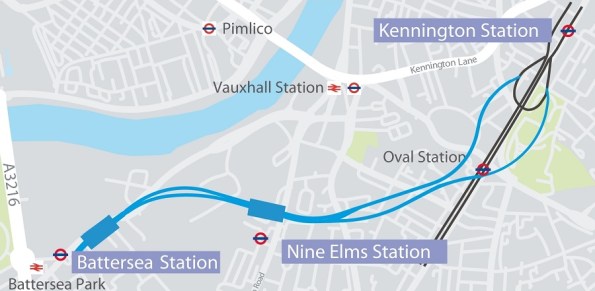

The project is a 3.5km extension of the Northern Line which will continue the Northern Line from Kennington with two new Stations at Battersea and Nine Elms. The line will have 100m overrun tunnel (under the cats and dogs home) which will serve to store two trains over night for morning service. That tunnel will eventually connect the line to Clapham Junction. The value of digging just 3.5km with two TBMs is apparently justified. Clapham extension too can’t be done now as there are no funds and apparently Clapham junction cant take the additional capacity just yet.

In outline, the project is split into four sites. Two stations at Battersea and Nine Elms and two shafts at Kennington. The box at Battersea will consist of the station box and a crossover box. The crossover box (space for trains to swap sides before they return) will be used as the launch tunnel for two TBMs (Tunnel Boring Machines). The station at Nine Elms is relatively independent other than they must be at depth before the TBMs arrive. The last two sites are the shaft that connect to the existing line at the Kennington Loop where the TMBs will be lifted out. The shafts will then remain as ventilation and emergency escape for the tunnels.

Joint Venture.

I understand that Ferrovial were brought onboard primarily for their tunnelling experience where as Laing are taking the lead on the station boxes and the shafts. Despite this the site office is a 50/50 mix from both companies. I understand there is a slight friction with the Spanish side of the team as they are very commercially savvy but see the role of a site/section engineer in a very different way. Commercially sensitive material is apparently spoken in Spanish which makes by ability to speak the lingo quite helpful.

Design management and leadership

Sorry Mike. No pictures.

You are sure to have heard this phrase before: ‘Sandhurst is the best leadership academy in the world’. I have always had mixed feelings about all that and whether we as the military are as good as the rhetoric, but maybe I’m wrong. I’m not sure if others have had similar experiences in the industry. There were plenty of ‘tense meetings’ in construction, though I can imagine more shouting goes on away from the client; I didn’t really expect it in design though.

I’m not sure if there is any more background to him but the project manager on the Ft Drum NCOA is apparently a known bully. This week’s conference call a shouting match ensued between him and the generally mild mannered design manager. It certainly wasn’t my place to jump in and so I joined my colleagues in gently turning down the phone volume and letting the storm pass. Why? The issue was about a design freeze that had been issued by the project manager due to a VE modification (cutting a 12” slice out of the centre of the building, which clearly has architectural and structural implications). The project manager was arguing that although drawings couldn’t be updated there was still other work that could be done.

So what? The issue with the management of the project in my opinion comes down to two things: communication and the long handled screwdriver:

- On the communication front the project is terribly managed. Meeting minutes are only produced because the Fire Protection Engineer and I produce them as a de facto rather than de jure Other information is continually asked about despite there being a well set up folder structure for IM. Finally, and most relevant in this case, no one had actually told my office that we were to stop modeling; which I pretty much spent the whole of last week doing!

- As for the long handled screwdriver, the project manager is stepping on the design manager’s toes. He has been directing some of the designers and clearly keeping the design manager out of the loop; linking back to communication. Also, and it may just be a bugbear of mine but he uses the word ‘I’ too much as if all the decisions are his; which clearly they are not as he is neither the designer nor the client, rather a conduit for information.

Coming back to the shouting match what really surprised me, and the other Baltimore designers, was that they were arguing in front of us. Whether there are issues in the background or not this does not appear to be the basis of good team building.

Design Process

Design process

Background

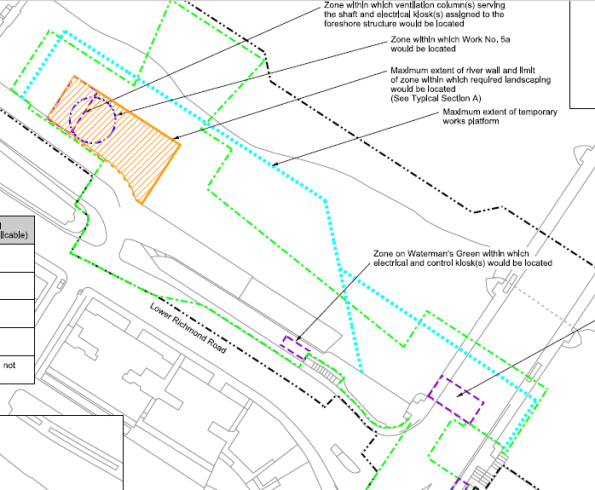

The method of getting sewerage from the current outfall point in the Thames into the new Thames Tideway sewer is via a series of chambers and a 30m shaft. At the Putney site these chambers are located on a foreshore site. To facilitate the construction a cofferdam is required.

This blog looks at the approach taken to decide how to size up some piles for design development.

Putney Embankment Foreshore – End state river wall is the rectangular box in the foreground.

Durability

Tideway (the client) require a 120 year design life for all structures. This is onerous but after Guz’s recent blog on his river travels I can see why there is pressure to prove everything meets the design life.

Tender stage

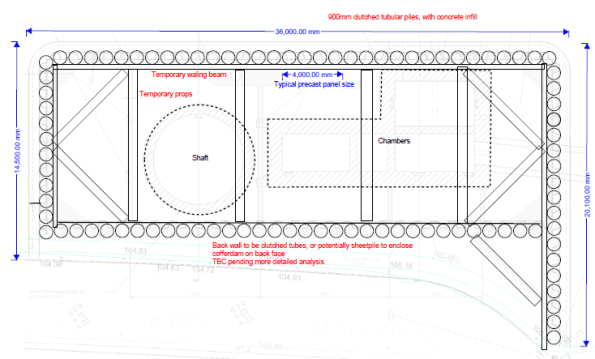

Tender documents had the permanent cofferdam as a secant wall. To enable construction an outer vast temporary sheet piled cofferdam was proposed.

The blue dotted line is the extent of the tender document sheet pile wall. The orange box is the proposed site location.

The contractor’s tender submission was an optimised design by combining cofferdams to have a single thicker sheet piled solution which would satisfy temporary and permanent conditions.

Contractor’s tender submission – Sheet pile wall to act as a temporary and permanent wall.

The issue

Proving a sheet pile will last for 120 years is a bit tricky. The River Thames is fresh (ish) water but the fact sewerage is being discharged nearby creates a risk of microbial induced corrosion which erodes steel and makes arguing the case that all will be fine (as in only 1 or 2mm rather than 5 or 6mm difficult). Unfortunately the UK national annex is more onerous than the main eurocode, I.e. assumes more corrosion occurs.

Plan B

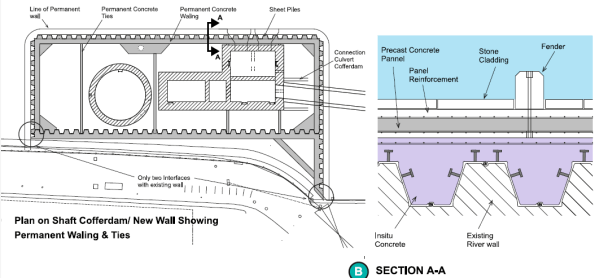

The contractor is keen to use a cofferdam which works in both temporary and permanent cases so have asked the Arup-Atkins joint venture to look at tubular piled options. Steel with concrete encased inside. This can be split into 2 cases. 1. Steel is non-sacrificial and last 120 years and 2. It does not.

Tubular pile option – outline sketch only

How does the cofferdam get built?

- Modelling the construction sequence for either case is the same:

- Install cofferdam

- Install top prop

- Dewater

- Excavate to formation level

- Install base slab (acts as a bottom prop)

- Wait 2 years while shaft is excavated

- Move to drained conditions.

- Re-fill cofferdam/construct internal chambers to underside of prop level, back to undrained conditions.

- Remove temporary top prop.

- Finish cofferdam/structures, apply surcharge

- Excavate and place scour protection.

- Allow for some worst case tidal and tidal lag.

- Long term case – move to drained conditions.

- Case 1 – steel remains, Case 2 steel does not.

600mm tube option shown below.

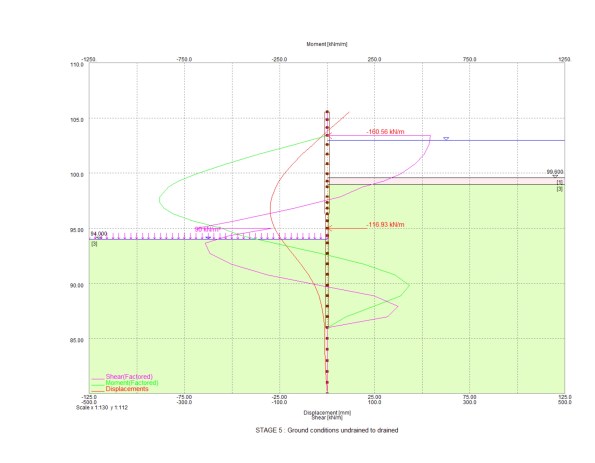

Stage 5-8 in stages above – excavation to full depth with base slab at drained conditions

Final stage with deflection of wall shown in red (105mm) and bending moment in green (1MN)

Stiffness

Understanding shear, bending and deflection throughout the sequence was key. Various pile diameters were tried but this was simply an adjustment of stiffness in the Frew model. EI based on section size, steel and concrete Young’s Modulus. 0.7EI and 0.5EI were used for temporary and permanent concrete strengths. The difference for the 120 year case comes at the final stage where only the section properties of a concrete section above bed level can be taken into account, i.e. a reduction is stiffness. More onerous is the reduction in moment capacity the section has without a steel pile included.

The results

After trying various tubular pile sizes I got to a 600mm pile for both cases above as worst moments were in temporary case (max excavation rather than maximum fill height), so loss of steel section was not an issue as final stage was still below moment capacity.

Unfortunately I made a stupid error in the fill material (somehow I assigned a granular fill a high cohesion value) within the cofferdam which meant I had lower bending moments in the long term than I should have. That was identified before presenting to the contractor so I only lost face internally.

The amended results showed that a 600mm diameter pile works in the non-sacrificial case and a 900mm diameter pile works in the sacrificial case (due to reduced moment capacity).

End state deflections were somewhat high (100mm) but all of the modelling was done at DA1 combination 2 which is not the case at SLS. Also some of the water profiling is a little unrealistic (high level inside the cofferdam, very low tide outside). There is, however, some assumed stress lockins. For example early stages see the wall bend inwards, later stages see it pushed outwards. Difficult to know if this will actually occur so this is a probable case and greater deflections might be expected.

Cladding

The front face of the river wall has stone faced cladding panels which need to be fixed to the piled wall. The connection detail raises questions on durability – casting in stainless steel brackets works but if you touch a stainless steel bracket against a mild steel pile you get greater corrosion so some thought is needed to avoid that. Additionally, final deflections up to 100mm although equate to a small angle mean the top of the cladding is off-set further in order to backfill between the cladding panels and wall. This means the cladding load acts at a greater distance causing more deflection. It also makes it harder to pour something in between the piles and the cladding panels.

Design meeting

After a week of looking at all the options the proposed solution from Arup-Atkins (us) was the 600mm pile thick enough to corrode and be acceptable in the long term. I.e. a section size that was acceptable in the long term and then a corrosion allowance added. The contractor is now going to price this option. Although more expensive than a sheet pile option, it is cheaper than doing the vast sheet pile cofferdam and there are significant savings in temporary and permanent works (fewer internal props and ties needed because of the stiffer piles).

There was sensible input from the contractor about ease of installing 600mm diameter piles versus 900mm as well as lots of points about presenting a solution which meets the client’s durability concerns.

Outcome

We wait and see what Tideway say – they may reject all options and say build it as per the tender documents. If this is the case then I wonder what the point of early contractor involvement is.

Lessons

The whole issue and reason for having to look at alternative options is because of durability concerns raised by the client. The optimised contractor solution was/is a sensible plan and on a pain/gain contract it is worth trying to make savings.

The best thing I see having gone once around the process is developing multiple options to give the contractor the choice of what to present to the client. This enables a solution to be put forward on technical merit.

The plan to get the tubular pile costed before presenting to the client presents risk (for the contractor) has failed because of how busy the commercial team is right now which might turn out to be an issue.

I have learnt a lot about the importance of how something is to be done without the need to go into detailed calculations – certainly the case at concept design stage.

Temporary works jetty solution to build the new site. All by river approach demonstrated with barge removing spoil.