Safety in Design

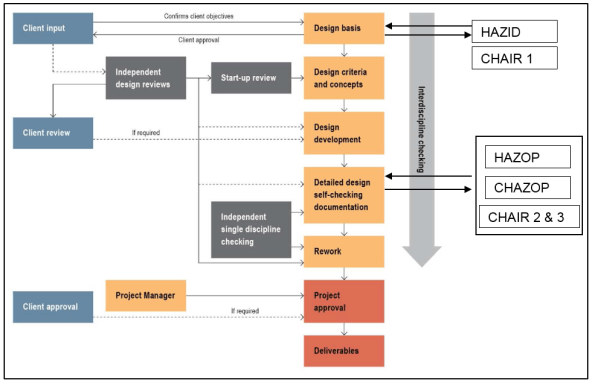

Since arriving at KBR I have been involved in various elements of Safety in Design (SID). I don’t recall the subject being touched on in great detail on Phase 1, but it forms part of the core business of the design team. This blog gives at introduction to the systems used by KBR and some of the key issues I have witnessed so far. The basic steps in the KBR SID process are covered below, how the fit into the design process is illustrated in Fig 1.

Hazard Identification (HAZID) studies are generally conducted at an early stage in the design by senior designer and the client. Identifying key hazards early means that they are revealed before significant costs have been occurred in the design process. It also means that if they are unavoidable further risk reduction measures are actioned during the detailed design.

Construction Hazard Assessment Implication Review (CHAIR) is a tool to assist designers, constructors, clients and other key stakeholders to come together to reduce construction, maintenance and demolition safety risks associated with a design. The design can be considered as a whole or sub systems. Generic guidewords are used to identify hazards associated with three stages of a project; concept, construction (also including demolition) and maintenance and repair.

Hazard and Operability (HAZOP) studies are carried out as the detailed design is beginning to go firm. It is a detailed hazard and operability problem identification process, carried out by a team generally including representation from the client, operators/maintainers, suppliers, designers and installers. The design is broken down into ‘nodes’ related to how the system is designed to operate. Then various guidewords are used to provide out of normal operation scenarios. For each one the risk, cause and consequence are recorded, along with a solution if agreed or an action.

Control Hazard and Operability (CHAZOP) studies are carried out once the control narrative is complete. Similar to the HAZOP the CHAZOP study uses a number of guidewords to study deviations from design intent caused by computer/control issues.

Although this looks like a very linear progression in reality it is very iterative with the feedback from various stages been integrated and reviewed before the next. All of these processes are recorded and form part of a SID report for each project. This then provides a log of how a design developed and why decisions were made. It forms a key piece of evidence should something go wrong with a plant in the future.

Fig 1 – The Design and SID Process

So far I have facilitated a couple of HAZOP and CHAIR meetings already and taken part into a few more. Some of the issues I have picked up so far include:

- The importance of the leader – the lead of the workshop is a key role. They need to keep the group on track, ensure all key information is recorded and prevent discussion going down various potential rabbit holes.

- Time Management – The key to the meetings is to identify hazards not solve them. Should a point take more than the allotted ten minutes it needs to be reviewed separately.

- Time Allocation – The workshop needs to have sufficient time allowance and should be broken up if possible. Generally the sessions I have been to have lasted all day and the level of interest thus the quality of the output drops throughout the day. Sequencing to allow the high risks elements first can also assist with this, as do sugary snacks.

- Design Quality – The design needs to be of sufficient quality and detail to allow the workshop to take place, otherwise it’s a waste of everyone’s time.

- Preparation – The designs need to be sent out in ample time for everyone to review and submit comments prior to the workshop – otherwise you risk the workshop disintegrating into a design review.

- Attendance – Make sure the correct number of people are present. Too many and the discussions take too long, two few or the wrong attendance and key items could be missed.

- Variations – Often this is the first time the client has looked at the design in detail and from my experience so far they try to use the opportunity to add things to the design. As mentioned previously the purpose of these workshops is to identify potential hazards, not work out who is commercially responsible.

Matt, some great E2 examples here. We don’t really have anything as formal in place at NDY, or not that I’ve come across anyway.

Is this part of a process everyone who designs gets involved in or is there a central department that caters for all projects’ safety in design?

Fran, usually the design lead for the project in question will attend, plus any SME’s they may want, which could include a civil if they are mechanical background and vice versa, a process engineer or controls engineer, so within the office most people get used at some point. The workshops themselves are facilitated by a HAZOP/CHAIR lead, there are a couple of qualified individuals in the office, but this is not their primary role they just happen to have done the course.

Matt

Interesting stuff, Mike will be all over this at BP, we used to do this on a regular basis in 521 for water safety and I found the principle very easy to understand. As Fran highlights some organizations wont have the formal HAZID/HAZOP process but doubtless everyone has seen it at some point. Most design reviews/gateways involve some or all of the elements you provide,

Some very good reflections on the process too, you’re right we don’t cover this on phase 1 – maybe something you can bring back with you and promote at 170?