Archive

MREP

Day 4 in the GHD house.

In September 2014 the Victorian State Government made an election commitment to extend metropolitan rail services from South Morang to Mernda in Victoria, Australia. The extension is estimated by the Government to cost between $400-600M AUD. The project seeks to enhance connectivity to Mernda through the extension of the existing railway line, including two new stations and associated stabling (train parking) and infrastructure works.

Victoria’s State Budget for 2015-2016 committed $9M AUD to develop the business case, undertake site investigations and commence any necessary land acquisition and other associated project development activities for the MREP (Mernda Rail Extension Project).

The State Government assembled the LXRA (Level Crossing Removal Authority) who approached GHD for interim Technical advice in order to prepare a reference design fit for tender. The program objective of GHD is to provide the engineering and associated professional Technical services required for the preparation of tender documentation relating to the extension of the MREP. Effectively, the LXRA did not know exactly what they wanted and asked GHD to tell them what they needed.

GHD has subcontracted some of the works to AECOM who are assisting in design. The completed reference design will include Technical documentation required to inform a request for tender (RFT) to go out to market as part of a collaborative design and construct (D&C) tender process.

I am currently employed by Victoria Transport Infrastructure section in GHD. The team I find myself in is responsible for producing the Specification for the MREP, with SMEs from various stakeholders (road, rail) assigned to the team as contractors. The MREP will be completed using the AS 4300-1995 (Australian Standard General conditions of contract for design and construct). The Specification section of the contract is comprised of 4 parts:

- General conditions

- Stated purpose

- Technical Specification

- Appendices

To describe it simplistically, the contract is an AS4300-1995 Design and Construct with the exception of the Technical Specification which is ‘bolted on’ after completion by the relevant parties. The first challenge is that there are no drawings yet. The Spec and drawings are being produced concurrently across 3 different office blocks in Melbourne and communication is poor. Time is critical and meetings are viewed as a waste of time when people would rather be getting on with their day jobs in order to meet tight deadlines.

The second challenge lies in getting road and rail authorities to present their Specs in a uniform manner.

The third challenge is the referencing of work. GHD has fallen foul of contradicting itself in past Specs. To manage this risk, we intend describing an item once in the Tech Spec and then referencing that section throughout. The GCC (General Conditions of Contract) and GSoW (General Scope of Works) will then have to be referenced to the Technical Specs. The issue here is that neither the GCC nor the GSoW have been written yet.

We have 3 weeks to produce the Spec for the client and I am responsible for ‘managing the production of the document and ensuring the Specification and the design drawings are coherent and not contradictory’. I’m still trying to work out what my job title is supposed to be…

Chalk and Cheese

I am by no means the computer room cooling specialist at the design office but I have been given another computer room cooling survey job to do. When the work was suggested I jumped at the chance to actually put into practice some lessons learnt from my work at Ft McNair by repeating the process, something I haven’t had the chance to do too much of. A good tick for C4.

The job is a survey and cooling design solutions for the communications closets in the ‘big shop’, USACE’s HQ in Washington DC and the reason I was selected is again because I am the cheapest engineer in the office. This has led me to two thoughts. Why is it always the communication closets that we get called in for? And to compare the clients.

Please won’t somebody think of the communication closets!

Both at USACE HQ and Ft McNair (https://htstrial.wordpress.com/2015/11/11/the-blind-leading-the-blind/) the main server rooms are well served with independent cooling systems. However the communication closets, which largely contain switches for VOIP phones and computers as well as some AV equipment, do not have specialist systems if they have cooling at all. My thoughts of why are:

- If communication closets are added retrospectively as part of a small refurbishment dedicated cooling is either not considered or gets deleted to bring a project under budget because it is a discrete, and possibly disproportionally large, cost.

- In new builds or large office fit outs, because the rooms are small and dispersed by their nature, they are just tied into other systems. Again either because it is easy, or cheap unlike dedicated DX or VRF systems.

- Modern equipment has a higher heat density than its predecessors.

- Creeping regulation. It has been recognised for a while that server rooms require security, indeed I wasn’t allowed into one as I am a dirty foreigner. However the security regulations for communications closets has more recently upgraded them noting their risk. Therefore putting a large efficient grille in the door, leaving the door open or even just putting the switches in the main office are no longer acceptable. But asking the ‘so what’ has been a little slower…

- Any other opinions welcome.

Differing clients.

These clients really are chalk and cheese. This was highlighted by a number of the actions of the USACE HQ team.

- They invited stakeholders. Though I didn’t see who would be paying, I got the warm fuzzy feeling that it wouldn’t be an issue. The facility manager and his assistant, who understand the building which is leased, were there as well as the guys who actually worked on the systems in the rooms. And they were all engaged with the effect they wanted to achieve. At Ft McNair we had a quick chat with the FM, were told they wanted portable coolers, and palmed off with a disinterested programmer who roughly knew where the rooms were.

- They were compiling lists of equipment and its heat rejection. This really is the boring part of the job, which I would be doing, so in my eyes they can pretty much do no wrong. Ft McNair did not have equipment lists. Though presumably they would need them for other purposes than just ours.

- I won’t labour the point but they also had as built plans, answered our RFIs on the spot and were able to talk about emergency power and would research more into the availability of capacity.

So what? Well they actually seemed engaged which made the survey straight forward so, rather than measuring rooms and photographing nameplates, we were able to think and talk through wider issues and solutions. The budget is a lot smaller at $3,000, vs $50,000 for Ft McNair, and Mary has spent half of this just by spending a day out of the office. However, it doesn’t appear that access to money is an issue and as I will be doing most of the work it is irrelevant. My conclusion is not that they are doing the legwork for us because they are short of money, but rather that they are engaged with the project and want to get a positive solution.

4/5th PWRI Flowline Update

So…… it’s been a while since my last blog, for two main reasons. First, priorities and second, any blog would be a cut a paste of my last blog, since the same issues with material and ops support have been a recurring theme. That being said, I thought it was time for an update;

Situation

The 4th & 5th PWRI flowline is coming towards the commissioning phase but there are still issues cropping up. The materials are all sorted, although Ops Sp issues remain, and will always be an issue. I have summarised further problems below;

Power Tie in

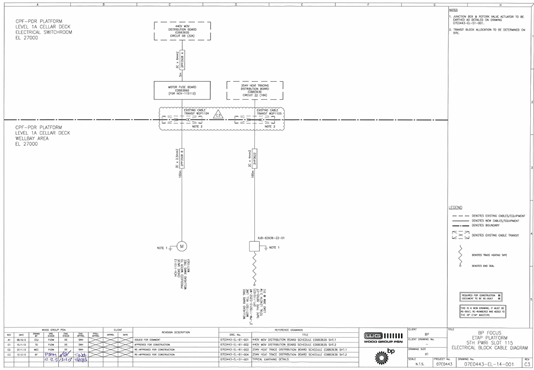

The diagram below shows the extent of the electrical work that has been carried out.

As you can see a fairly simple scope, with just trace heating and the choke Motor Operated Valve (MOV) to be tied into their respective DBs. Unfortunately when the elec techs went to tie these into the DBs, it was identified by the platform that the cabinet could not be isolated as it removed the ability to remote operate the rest of the choke valves. The following options were considered for the MOV tie in;

- Isolate the DB and have an inst tech with a radio standing next to the choke valves in order to manually operate as required. A risky option as control would be minimal and delayed. This was not considered further.

- Tie into alternative DB. Nearest DB is some distance away and it is unsure what it currently powers. More material would be required, a workpack change would be required and an investigation would be required to understand what it powers. Not considered further.

- Do nothing and wait for the next outage. This would have significant cost implications, since the rate of PWRI is limiting hydrocarbon production and is relying on the 4th and 5th in order to increase. Not considered further.

- Do nothing, but run flowlines in manual, and trim using PWRI flowlines 1,2 & 3. MLCOA.

Decision. Option 4 was chosen as the MLCOA, but requires buy in from everyone involved. It will be necessary to carry an A(Qualified) ‘punch list’ item through System Handover (SH-1), which is not really the norm and makes people twitchy, as it has been known for punch list items to be forgotten about. It also required a growth request to be submitted to get the extra work into the outage in Apr, which is already over booked.

The same issue exists with the trace heating, but an alternative DB has been identified as a temporary solution, until permanent tie in during the outage.

Instrumentation wiring modifications.

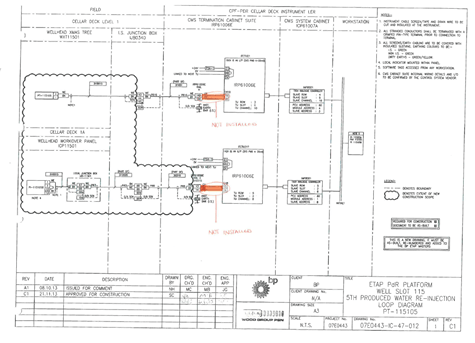

18 months ago, ABB carried out modifications for this project, specifically software upgrades and patch wiring modifications in order to get the instrumentation signals from the transmitters to the control room. Two weeks ago, we went into the cabinets to terminate the instrument wiring to find that the modifications had not been completed. See below.

As you can imagine, there were a few phone calls and finger pointing from both sides, but essentially they hadn’t completed all what there were supposed to have done. That then turned into 2 weeks of us trying to get them to commit to dates and availability, but them not doing anything until a PO had been raised to pay them, which takes time to generate and required ABB input, which they were also dragging their heels about. Of course the discussion about why we are paying them again to do something they should have done is a different discussion. We now have someone offshore to complete the mods.

Literally as I type, I have just received an email which states that the mods required would have to be done in a shut down due to the other wiring in the cabinet. This is significant, as the chances of commissioning and putting into service the flowlines now is almost certainly impossible and will have a financial cost of c. $100k a day in deferred production.

Of course there will have to be an investigation as to why the work wasn’t carried out in the first place, I’ll let you know the outcome.

Pipe support clash with Line of Sight gas detector

A few weeks ago it was identified that there was a clash between a pipe support spring can and existing pipework which is part of the deluge system. This required a re-design of the pipe support and was moved 90mm to avoid the clash. Shortly after, it was identified that it now clashes with a LoS detector system which picks up gas leaks in the well bay, which is quite important.

It has been painful, but there is now a way forward by moving very slightly the LoS detector. This took a week to resolve and discussions with a whole host of people to get acceptance which didn’t require a separate Management of Change (MOC) procedure.

Summary

This project continues to throw up issues, which take a significant amount of time to resolve. There are of course a few questions that need to be asked;

– Why was the ABB work not completed as thought?

– Why has it only been identified now that the DB and cabinets can only be worked on during an outage

– How was a piping clash not identified in the design phase?

I will keep you posted, as the significant cost implication will cause a fair bit of noise.

NLE – Battersea Station

Last time I spoke about the project in general so here is a bit on the detail of the project, specifically the Battersea site of the NLE (Northern Line Extension).

Station and Crossover Boxes

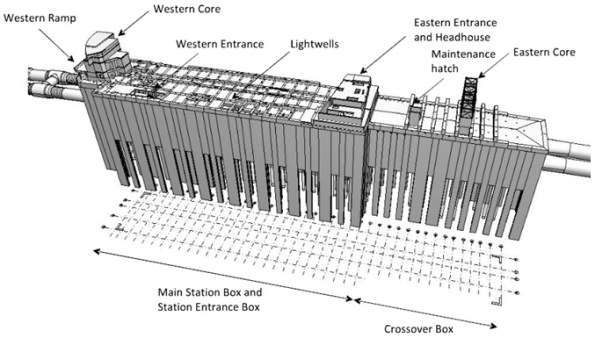

The whole Battersea site simply splits into two boxes. The Station Box is the bigger of the two and is where the majority of the station is going to be situated. The crossover Box is smaller (about a third in length) but still as deep. This box is simply allows the trains to cross from one side of line to the other before it pulls into the station. The Crossover Box is also the launch and access box from where the TBMs will be dropped down and also act as the area to dig out the launch tunnels.

The design for this is essentially Ex Cofferdam on a much bigger scale, just replace sheet pile walls with Diaphragm Walls. Although the D-walls themselves are being constructed inside a 5m sheet pile wall secondary cofferdam. The D-walls vary in panel width (2.6m to 4m) by 1.2m and are saw toothed (see picture), essentially because the shorter ones are as deep as the bottom slab and the longer panels which are 60m long are mostly end bearing onto the layer of Thanet Sands. More on the Thanet Sands another time.

Tunnels

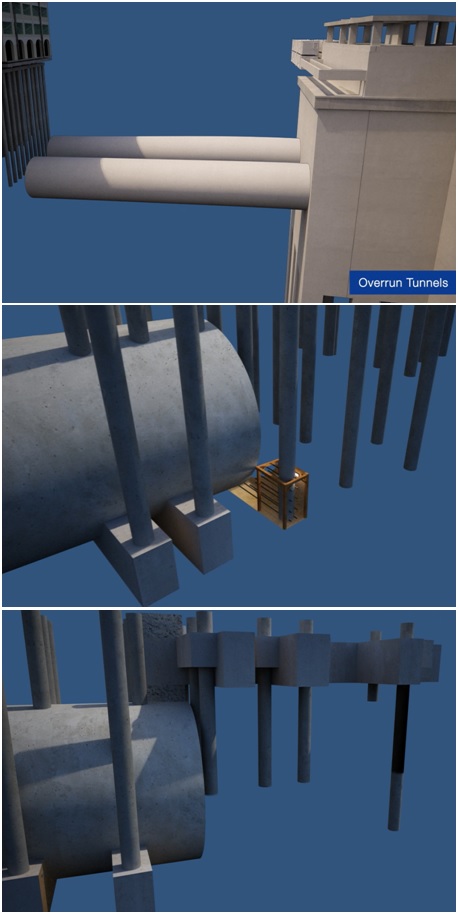

The tunnels are relatively self explanatory except for the bits that won’t be done by TBM. The first 200m on the East side (TBM launch tunnels) and about 200m of over-run tunnel on the West side will be dug manually (well mechanically but not by TBM) and then spray lined with concrete. The over-run tunnels are quite interesting as these are apparently part of TfLs plan to secure a future extension to Clapham Junction (no present funding available). These overrun tunnels will go through the pile foundations that the Battersea Cats and Dogs home.

There is cunning plan to dig up to the piles and prop around them/ tie them together in a move that the NLE Construction Manager admitted to me “will most likely break all the windows in the building”. Though they did get a massive extension that triples their space to keep them happy. The following pictures are a bit of that sequence from a video that shows the process.

Muck Conveyor

Finally worth mentioning the much conveyor which has been installed to allow muck to be carried away by barge. From a cost point of view it the £16 per tonne compared to around £300 per tonne by road seems an easy decision but when you factor in the £5 million initial cost and maintenance of the conveyor over the length of the project it nearly breaks even. But it does save hundreds of road moves through London which goes a long way to reduce carbon emissions and keep the locals happy. At present the conveyor is loaded from a muck bin and we are moving about 1000t a day. Eventually the conveyor will extend to the bottom of the crossover box and will connect directly to the back end of the TBM running 24/7 (about 4 barges a day).

The project to date

As we speak, Cementation Skanska (principle sub-contractor) are about 2 weeks away from finishing D-wall construction in the crossover box along with a few weeks of rotary bored piles in the centre (1.8m to 2.4m in diameter). Cementation Skanska are very much on the critical path and will be handing over parts of the box to us (FLo). So where as so far the pressure and risk is somewhat on Skanska it will soon shift to us to prep the crossover box for the TBMs. As I have quickly learnt, anything linked to the TBMs are pretty much on the critical path.