Archive

Is one crane enough?

The Problem

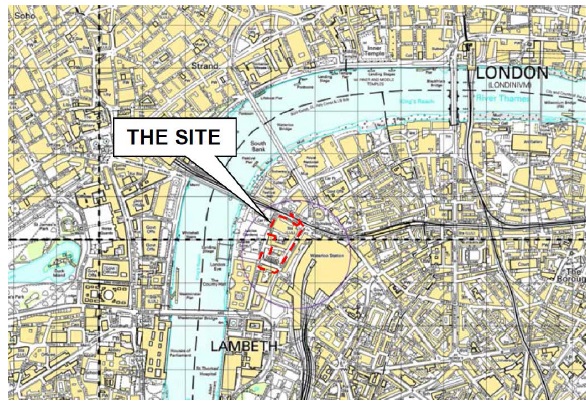

In a skyline full of Tower Cranes (TC) and rapidly rising high end residential and commercial projects, I confidently assumed that the ability to move construction resources around each of the capitals many project sites was a well-managed logistical challenge. Unfortunately, one of the seemingly obvious issues currently causing some contention on my site is the limited availability of heavy lifting equipment. You would think that providing enough lift capacity for a large construction task is a simple thing to get right but as it currently stands, the project has only one TC supporting all construction activities. That comprises a lot of lifting operations; particularly when you consider it includes support to permanent works on three different buildings, temporary works, scaffolding movement, routine site support tasks such as waste removal and welfare setup, concrete placement, unloading of frequent deliveries and support to a MOLA (Museum of London Archaeology) investigation ongoing in one isolated corner. It is clear that almost all work activities on site requires lift support in one capacity or other.

From a project management and commercial perspective this creates an interesting working environment. As a direct result of the apparent shortfall, the subcontractors are now competing for the limited available crane support on a daily basis. In many cases these same contractors are subsequently struggling to achieve progress in line with their own ambitious build schedule because, according to every daily progress summary I have attended so far, the TC is unavailable to move equipment and resources across our very constrained site.

Issue Mitigation

To attempt to mitigate this issue, the principle contractor have temporarily allocated control of TC1 to the sub-contractor completing the essential works on the critical path. As it presently stands that priority lies with the slip form construction of the central concrete shear core in the main tower, currently up to level 2. This core is being constructed in two sections due to its size. For context, each half of the slip form requires approximately 50 crane lifts per day to feed a 50 man gang with all of the steel, formwork and resources required to maintain the scheduled form rise of 1.4m per day. This estimate only includes lifting the resources from the storage area up to the formwork and does not also include unloading upwards of ten lorry deliveries of resources each day. Movement of scaffolding, concrete decking formwork, and the lifting of structural steel frame elements into position are all in competition with the slip form for crane time.

The project management team are also now considering options to reduce the impact of this crane issue on the works programme. These include the installation of a temporary crane (Limited capacity of only 3 Tonnes) in addition to weekend and night works, both of which will increase the overall cost of the works in the short term.

Cost Implications

In numerous situations many of the contractors have brought in labour and resources to complete tasks, only to find that the crane has been allocated in support of other activities. As a result there are frequent occasions where a contractor has workers and resources on site yet is unable to complete scheduled work, at significant cost to both the main contractor and sub-contractor. The resultant effect is that other structural elements and less critical works are now falling weeks behind the original build schedule. This inevitably causes dispute between various sub -contractors which requires careful management and the occasional element of low level dispute resolution.

I suspect this will remain a considerable project management issue until TC2 and TC3, self-climbing cranes suspended from the main shear core, are installed once it reaches floor 10. In the long term it also has potentially significant contractual and commercial implications. Brookfield Multiplex almost exclusively use sub-contractors for all construction aspects on their projects. The only element that they seem to provide themselves is the provision of the Tower Cranes. When the sub-contractors designed their own programme and tendered for the works package they considered availability of lift in accordance with the main contractors lifting plan.

Who is to Blame?

As you would expect on a project of this scale (£460m), identifying and apportioning responsibility for the issue is an ongoing priority. On this project there appears to be an underlying discrepancy regarding the understanding of crane availability during the early stages of project procurement. The Project Managers (PM) formal position is that all the sub-contractors were informed that there would only be TC1 on site at this stage of the project. He is therefore of the view that they costed and programmed the work on that information and therefore responsibility for delays and subsequent costs lie solely with each sub-contractor. The sub-contractors by comparison have stated that during the initial tender process they were told there would be a second TC available by this stage, effectively placing responsibility for delays at the door of the main contractor.

Though all parties on site are working hard and compromising for the benefit of this project, it will be interesting to see where overall responsibility for delay costs fall should elements of work continue to fall behind schedule. As a result, the sub-contractors complain regularly about the lack of crane time (every meeting), I assume to record the issue from their perspective before it leads to an expensive compensation claim further down the line. Likewise, the project management team appear to be strengthening their own position on this issue to allow easy apportion of responsibility elsewhere in order to protect the interests of their own profit margin.At the moment the lack of adequate crane support is not impacting on the critical path, but with weekly site running costs in the region of 300k, further long term delays arising from this simple problem are likely to have expensive consequences into the future.

Grab your Stetson and Run for your life..

Grab your Stetson and run for your lives!!! – BRISBANE CASINO TOWERS

What the client is selling it as.

Introduction. So I started work at Brookfield Multiplex on the Casino Towers project on Hope St in South Brisbane. The project is a 30 storey residential tower block with 6 floors of basement. The contract is a fixed price Design and Build contract for Metro Property Development. BM has taken on all of the risk with this contract under a fixed price and a tight deadline. Time and cost are paramount with tough liquidating damages for overrunning, so the pressure is on. Much of what the project team do is manage other sub-contractors and liaise with their contracted designers. Location wise the site is situated in an interesting area between two blocks of high-rise social housing whose occupants are none to happy about our work and have been keen to let us know by throwing their used needles over their balconies and into our site.

The clowns to the left of us

The clowns to the left of us

The jokers to the right

Stuck in the middle in poo or Acid Sulfate Soil (ASS)

Contract out risk. At the moment we are at excavating the basement. The team has little to no experience of excavating basements and have sub-contracted this phase of a contract to Delta on a Design and Build contract. Delta in turn have sub-contracted the propping system to QPS, with Delta taking on the bulk of the mud moving for themeselves. Unfortunately BM sub-contracted the piling work out to Franki Pile and as the supports and wall work as a system are still carrying much of the can. Wailers are clashing with the future floor slabs and given that the site is at a slight angle, it has all got very complicated.

![Q2454-0001[01] (1)](https://pewpetblog.com/wp-content/uploads/2016/03/q2454-000101-1.jpg?w=595)

Prop Layout at first level of supports the remainder is Ground Anchors

Managing Sub-Contractors. While BM has contracted out the basement they seem to have little leverage into motivating the sub-contractors. They have been accused by the subbies of micromanaging but, it is clear that the subbies are not up to the task. The secant pile wall/propping system has not been designed for construction loads and we can’t even unload stores close to it. On the flip side it would seem that with only one engineer on the project up to this point the scale of the task has over matched him and BM have not asked the right questions before they got to this point.

Struggling to fit the whalers in place

Propping system. QPS are the subbies in charge of the propping system and are more used to ground anchor systems and have struggled with installing a workable propping system. This is the biggest job they have done and frankly it shows. My key criticisms are they insist on welding everything on site, as opposed to preparing off-site and connecting with bolts on site. At the last count 9 of the first 10 welds have failed and need to be redone. They have not really thought about how it will go together and many items have arrivied out of tolerance. The project is now about a month behind schedule. I took a ride out to their fabricating facility. There is a huge capability gap from what we saw at Nu-steel and what QPS can produce. The whole prop system should have gone in last week but the wailing system still hasn’t been fitted. The picture below shows Delta struggling to get the end wailer into place.

The journey of the whaler from factory to floor

H&S. So there are so many issues I scarcely know where to begin. My first appointment was at BM headquarters in the Central Business District. The meeting was about enforcing stricter H&S standards on the various sites around Brisbane. The overarching thing was about moral courage (where have I heard that before) and about safety in design. Monday was a scheduled no work-day so I had the opportunity to inspect the site without any of the sub-contractors (or unions) around. The sub-contractors approach was certainly different from anything I has seen in the UK’s. The stairs into the basement had been undermined by the heavy rains and were pretty rickety. I was also struck by the confined nature of the site and the little separation of people and plant.

Our Union Rep checking H&S standards -integrity is not his strong side. You can see the plunged columns that will support the working platform.

Labour disputes. There have been real issues with unions in Queensland. At the start of the week a construction site on the next street had been shut down after a union walkout. By Tuesday, it was our turn with the union rep/commissar proving his wide and diverse vocabulary regarding his concerns about H&S on site. The union used the rickety stairs and the lack of any other alternative exit to shut down the site and to be fair he had a fair point. However, you can see the reps keen interest in PPE as he encourages the Delta employees to ‘knock off’ for the weekend on Friday.My role – Resitting Exercise Cofferdam, working out how I can get an excavator to move the ASS without exceeding the maximum surcharge of 5 KPa within 3m of the wall.

Boundaries, Properties, Groundwater, Contamination…Constructability!

.

.