Archive

Moving to Site

Over the course of the last week it has been clear that 75% of the “Engineers” on this project are fixed by the processes around gaining permissions and submitting notices in order to comply with the Development Consent Order and Works Information. Consequently a lot of the detail for our move to site has gone unexamined, good for me in terms of the experience I’ll get, but potentially bad for the project because they actually seemed to have believed the rubbish I put in my CV.

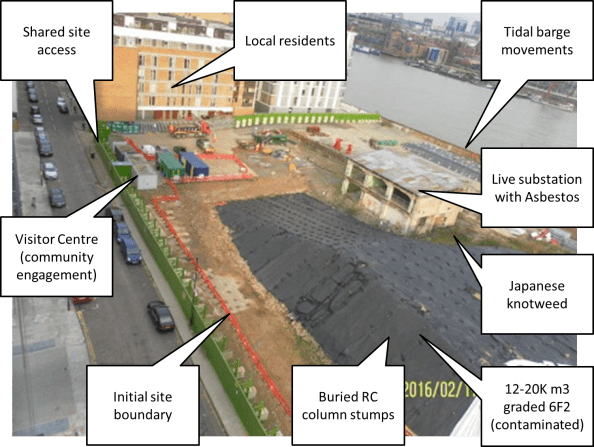

My team assembles on Monday to start the early works and the figure below shows some of the frictions that we will have to deal with.

Figure 1. Site “Frictions”

Liaison with Neighbouring Works

This looks like it could be pretty messy. The initial CVB site boundary will roughly follow the line of the orange Chapter 8 fencing, CVB will control site access from the road and are responsible for security to the entire perimeter (including the parts within others PCs areas. As the stockpile is reduced we will expand our site (land/insurance permissions will take at least a week to be circulated before I can move a fence). Eventually we will get enough land mass to start work on the foundations for our office block (in the location where the green and blue containers are).

Local Residents

There are a number of restrictions on site activities owing to the clauses within the DCO. Noise planning and emissions will be closely monitored for all site activities. Residents have a 24hr hotline number to call if they have any issues with noise. We also have to maintain a visitor centre on site which we man on Wednesday evenings, and hold fortnightly Community Liaison Working Group (CLWG) meetings. The surrounding area is 50% expensive river front properties owned by influential characters (rumoured to include Captain Jean Luc Picard), and 50% social housing with a number of residents that are shift workers or unemployed and therefore in the property during working hours.

Stockpile Removal

Another contractor is responsible for removing the 6F2 stockpile from the earlier (2009) demolition works. Initially they had planned to load a 1000T barge each day, then changed this to two 500T barges. In the test run they managed to load most of a 500T barge within the tidal window before a hydraulic line burst. Consequently the estimate has been revised to one 500T barge per day. The works were further slowed by the discovery of suspected asbestos. Works to remove the stockpile have been halted since last Thursday whilst we await confirmation. Perhaps a coincidence but the asbestos was found by the contractor appointed to remove the spoil, and it could significantly increase their fee if the waste was reclassified as containing asbestos.

Concrete column stumps

The contractor also discovered that the stockpile is hiding a number of concrete column stumps (approx. 600mm sq). The removal of these is currently within ‘a scope gap’ between the different PCs, however if it falls to CVB to remove they will have to try and do it ‘quietly’, due to the restrictions of the DCO by progressively drilling and injecting an expanding composite to break down the concrete in layers.

Japanese Knotweed

An area of Japanese knotweed was discovered previously and has been receiving regular treatments, although it cannot be completely eradicated. This will eventually need t be removed to facilitate our new site access prior to the office foundations being constructed.

All of the above are fairly standard site issues within London, but nevertheless should generate some valuable learning over the next few weeks, and as I commented on Jo’s post, a lot of potential for neighbouring contracts to impact on our works. I should add that we receive a brief on the Contract Execution Plan on Friday so I hope to explore how we might deal with any delays caused to our project as a result of delayed enabling works under a separate contract.

Chambers Wharf

I wanted to do a blog about the issues that we’ve discovered on site, but then I realised that I haven’t actually written a blog to orientate people to the site. Therefore I’ll do two smaller blogs. I’m not planning on orientating people to the tunnel in general, unless people have specific questions, as it’s covered on the internet here http://www.tideway.london/the-tunnel/construction-sites/.

This blog will briefly introduce the site, and the following one will look at some of the issues in detail. This has the added benefit of not boring everyone too much, and boosting my blog numbers so that I can compete with Holtham and Nelson for the ‘Most Prolific Blogger Prize’.

I am attached to CVB JV (Costain, Vinci G.P. and Bachy Soletanche) who are delivering the Eastern section of the Thames Tideway Tunnel (TTT). I will be based on the main drive site located at Chambers Wharf and my first task is to coordinate the initial site works, to establish site and the temporary (until 2023) office and welfare facilities. The initial works will include utility diversions, demolition of structures including an existing substation, installation of welfare facilities (to be delivered by barge), installation of the cofferdam and demolition of the existing RC jetty. Once these works are underway we’ll have time to focus on the shaft excavation for the TBM.

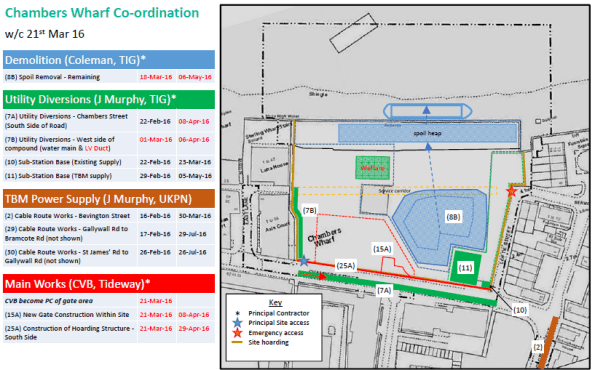

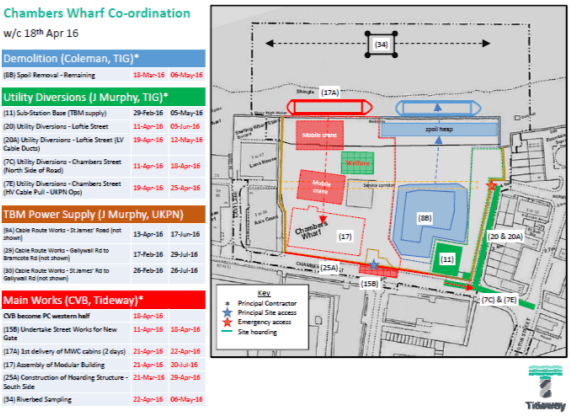

Within the site boundary there are 2 other Principal Contractors currently working. One to clear the site following demolition works conducted in 2009, and the other to divert existing services and to install services for the Tunnel Boring Machine (TBM).

The phasing and integration of the different work packages works well on paper (figures 1 and 2 show how it is meant to work), but having attended two integration meetings it is clear that the programme appears to be moving towards one long critical path. The other PCs packages have been delayed by asbestos, noise and vibration complaints, and barge issues, and is starting to impact on the phasing of our works. I will expand on these site issues in my next blog. In the meantime, if our works are delayed due to other PCs failings I expect there will be some interesting contractual issues, but I will have to wait until the Contract Execution Plan is released before I can comment on this in more detail.

As the plan stands we will be establishing our own site on 21 Mar 16. Further than this, our progress is dependant entirely on the neighbouring contractors spoil removal, but with a good wind we will soon be starting works to the hoarding which is a not insignificant 3.6 – 5m structure supported by kentledge or posts, and excavating for the foundations for the modular office building.

The office modules are due to start arriving by barge on 21 Apr 16 and will be offloaded by a 100T crane, and then lifted in to place by a 200T crane. Simples!

Figure 1. Site Integration w/c 21 Mar 16

Figure 2. Site Integration w/c 18 Apr 16

Soil out and Props in

We have had a very busy couple of days on Hope St, the big props are now in on the North side and the Acid Suphate Soil (ASS) is being rapidly extracted. We excavated 1368 cubic metres yesterday and over 600 cubic metres the day before. The site is starting to look better and progress is being made. Everyone is getting gradually less stressed.

It looks like the working platform will work and there is enough spare capacity in the props and wailer to cope with the lateral loads from the excavators (but we knew this anyway). I thought the photos might help future students on Exercise Cofferdam. Note the splices in the props, the ramp for outloading dirt and the excavator pairs working in tandem. .

SIMPLE SOLUTION TO A SEEMINGLY SIMPLE PROBLEM?

So drilling through a basalt extrusion proves rather problematic when the drilling arm to your rig snaps off and you are unable to recover it. You are essentially left with a snapped arm 20m deep in what should be a 1500mm pile which is now unusable.

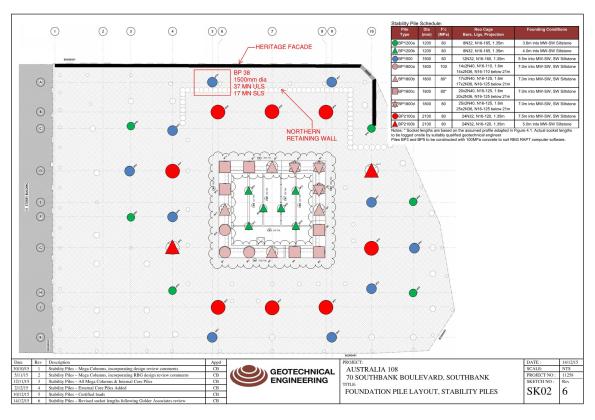

The piling subcontractors are on a design and build contract; they caused the problem, they will fix the problem at their cost. The solution, endorsed by the Multiplex team overseeing this part of the programme, is to concrete the original pile borehole (BP38) and construct two further piles (BP38-1 & BP38-2) either side of BP38, designed to carry the same loads. Simples!!

What risk did they fail to see?

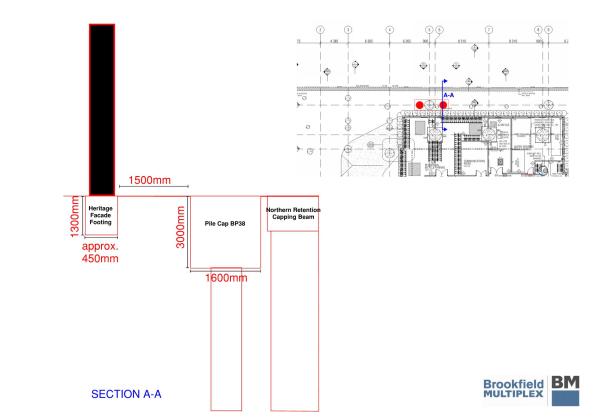

The position of BP38 is close to a secant pile retaining wall which is approximately 3.5m from the site boundary. There is a heritage façade which sits on strip foundations on the site boundary which is already in a pretty ropey condition and only supported laterally. The northern retaining wall enables excavation down to Basement Level 1. The construction of BP38-1 & BP38-2 was designed by the subcontractor’s engineer; construction went without a hitch and the two 1200mm bored piles have sufficient resistance equal to the original pile.

Position of BP38 in relation to site boundary and façade, and the northern retaining wall

Problem: It turns out that when you adjust the position and number of piles beneath a pile cap it alters the pile cap design. Funny that! The structural engineer (a consultant) produced a new design for a 1.6m x 5.4m x 3m deep pile cap to ensure the load (37MN ULS axial load) could be safely transferred to the piles. This means that an excavation of >3m is now required to construct the new pile cap. This is a >3m excavation in soft Coode Island Silt within 1.5m of the heritage façade.

Cross section detailing the parameters of the problem

Unidentified risk: This is an obvious example of unidentified risk, which could easily have been identified. Two subcontractors responsible for two areas of design and construct have not communicated before adjusting construction plans due to a foreseeable problem – everyone knew the basalt was in that location. The geotechnical subcontractors have simply fixed the problem they caused, thereby fulfilling the terms of their contractual obligations, without due consideration for the next phase of the programme, i.e. the construction of the pile caps. Multiplex have ratified the change because, I would argue, the people overseeing the construction have not understood and/ or identified the second order effects of the change.

Discussions: The first time I was enlightened to the problem was when the co-ordinator (construction manager) overseeing this phase of the programme sat getting rather stressed at how he was going to solve it. After two hours of ‘it will be fine’ and ringing round for advice he sent me the specifics when requested to have a look at. Two heads are better than one.

Options on the table:

- It is obvious that the excavation cannot be conducted to that depth without retaining the ground which supports the façade. But the question was how? My recommendations:

- a) Stiff retaining wall functioning as a cantilever capable of withstanding lateral earth pressures and deflections (combi wall perhaps?). This would give clear space in which to excavate at the front of the wall but would require greater efforts to construct such a substantial retaining wall. Also very risky due to the absolute necessity that the façade cannot move.

- b) Prop a sheet pile wall using ground anchors so the load is transferred to the ground behind the wall. Due to the proximity of the boundary (<1.5m) I deemed this infeasible; there would not be sufficient space within the boundary to fix the anchors behind potential slip surfaces.

- c) Prop in front of a sheet pile wall bracing against the northern retaining wall. This is very feasible ensuring that sufficient space is retained to permit excavation.

- Review the pile cap design with the intent of reducing the depth of the pile cap and subsequent depth of the excavation. This may have been an option prior to the construction of the two piles, but unlikely to be feasible now the location of the piles is fixed. A retaining wall would still be required but to a potentially shallower depth.

The solution: I recommended Option 1c as the way to go, pushing the piles where possible rather than vibro. The piling subcontractors are responsible for the design and construction of any temporary works to enable the excavation but were holding off to receive direction from Multiplex. Multiplex in turn has sent the problem direct to the geotechnical engineer consultants for their advice. Their recommendation: Option 1c.

Timing: The problem was first identified by the groundwork subcontractor on receipt of the new design drawings of the pile caps. This was on Friday, nearly three weeks after the failure to construct the original piles. Construction of the pile cap was due to commence on Tuesday giving 1 working day to come up with a solution and have the designs authorised. Needless to say, it is now Thursday and the team are still waiting on the design from the piling subcontractors and work is yet to commence on the retaining wall.

Lessons learnt?

- Communication is vital when the work being conducted by one subcontractor affects another.

- Second + order effects must be considered prior to making any amendments.

- Identifying risk early and consider this risk in re-mediation plans.

Additional remarks: In this case, the solution would likely have still been the same had the problem been identified when the original pile was deemed unusable. The upshot of early identification was that a retaining wall could be have been designed early and constructed immediately after the piles, thereby causing no delay to the construction of the pile caps.