Archive

NLE – Battersea Station

Last time I spoke about the project in general so here is a bit on the detail of the project, specifically the Battersea site of the NLE (Northern Line Extension).

Station and Crossover Boxes

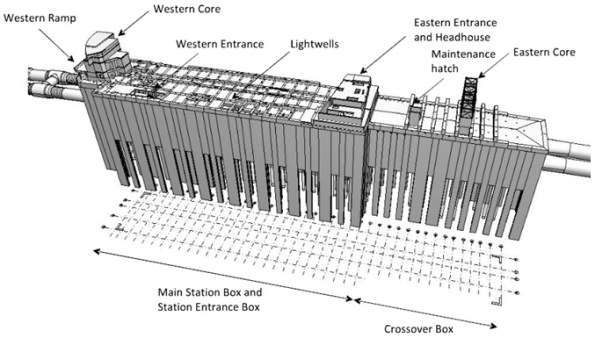

The whole Battersea site simply splits into two boxes. The Station Box is the bigger of the two and is where the majority of the station is going to be situated. The crossover Box is smaller (about a third in length) but still as deep. This box is simply allows the trains to cross from one side of line to the other before it pulls into the station. The Crossover Box is also the launch and access box from where the TBMs will be dropped down and also act as the area to dig out the launch tunnels.

The design for this is essentially Ex Cofferdam on a much bigger scale, just replace sheet pile walls with Diaphragm Walls. Although the D-walls themselves are being constructed inside a 5m sheet pile wall secondary cofferdam. The D-walls vary in panel width (2.6m to 4m) by 1.2m and are saw toothed (see picture), essentially because the shorter ones are as deep as the bottom slab and the longer panels which are 60m long are mostly end bearing onto the layer of Thanet Sands. More on the Thanet Sands another time.

Tunnels

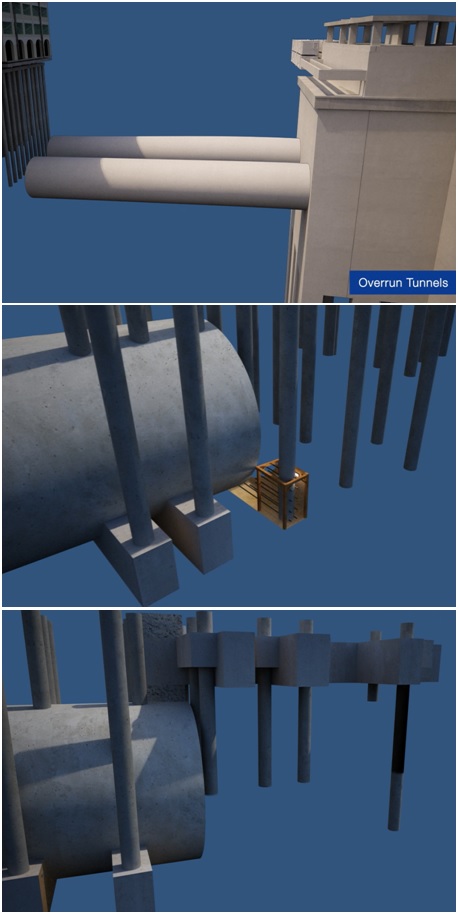

The tunnels are relatively self explanatory except for the bits that won’t be done by TBM. The first 200m on the East side (TBM launch tunnels) and about 200m of over-run tunnel on the West side will be dug manually (well mechanically but not by TBM) and then spray lined with concrete. The over-run tunnels are quite interesting as these are apparently part of TfLs plan to secure a future extension to Clapham Junction (no present funding available). These overrun tunnels will go through the pile foundations that the Battersea Cats and Dogs home.

There is cunning plan to dig up to the piles and prop around them/ tie them together in a move that the NLE Construction Manager admitted to me “will most likely break all the windows in the building”. Though they did get a massive extension that triples their space to keep them happy. The following pictures are a bit of that sequence from a video that shows the process.

Muck Conveyor

Finally worth mentioning the much conveyor which has been installed to allow muck to be carried away by barge. From a cost point of view it the £16 per tonne compared to around £300 per tonne by road seems an easy decision but when you factor in the £5 million initial cost and maintenance of the conveyor over the length of the project it nearly breaks even. But it does save hundreds of road moves through London which goes a long way to reduce carbon emissions and keep the locals happy. At present the conveyor is loaded from a muck bin and we are moving about 1000t a day. Eventually the conveyor will extend to the bottom of the crossover box and will connect directly to the back end of the TBM running 24/7 (about 4 barges a day).

The project to date

As we speak, Cementation Skanska (principle sub-contractor) are about 2 weeks away from finishing D-wall construction in the crossover box along with a few weeks of rotary bored piles in the centre (1.8m to 2.4m in diameter). Cementation Skanska are very much on the critical path and will be handing over parts of the box to us (FLo). So where as so far the pressure and risk is somewhat on Skanska it will soon shift to us to prep the crossover box for the TBMs. As I have quickly learnt, anything linked to the TBMs are pretty much on the critical path.

Hydraulic Modelling

I came across a reference to some software called EPANET the other day in a design report. Having done a little digging to find out what it is I thought it may be useful to the other E&M’s (or Civil’s) out there. It allows the modelling of water distribution piping systems, including junctions, valves, pumps and storage. As well as doing the standard hydraulic checks based on Hazen-Williams, Darcy Weisbach or Chezy-Manning formula, it can do model time based movement through the system allowing the modelling of residual chlorine amongst other things. It sounds impressive and what’s more it was developed by the United States Environmental Protection Authority, so its free. I haven’t had the chance to experiment with it yet, but it has apparently been used quite a bit on some of the Melbourne Water projects by various members of the KBR team.

http://www.epa.gov/water-research/epanet