A WHEEL WASH – YES HONESTLY THE STORY OF A WHEEL WASH

Occasionally, I read others blogs and I despair – I am not dealing with safety critical testing, I have not touched out of tolerance piles and certainly not experienced the delights of BIM. Instead I have been busy dealing with the position of a wheel wash… That is correct, the complexities of where to place a giant car wash on steroids. As an aside, the site right next door doesn’t need a wheel wash as NLE use a conveyor and barges to dispose of their spoil. In the process they stockpile all their muck right next to our temporary sheet piles creating surcharge loading that no-one has considered. However, that story is for another blog.

The Problem

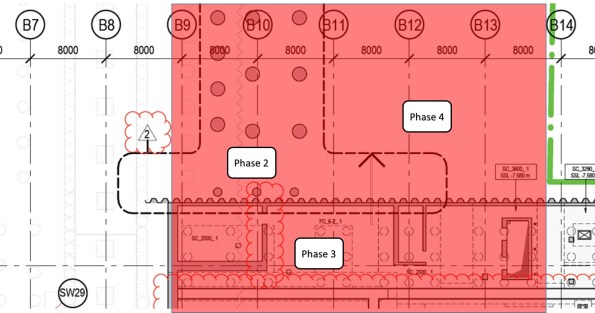

Approximately 120 muck away tippers per day, scheduled to increase, when Phase 3 start to excavate the basement levels. A shared access route – Phase 1 (Carillion), Phase 2 (Skanska) and Barhale are all on site (as principal contractors). To further compound the congestion Thames Tideway preparatory works have closed one of the public access roads. Finally, the location of the wheel wash must not clash with permanent structure works. The sketch below shows the access route highlighted in red with the locations of the different Phases and the permanent bearing piles, temporary sheet piles, and permanent secant pile walls.

Phase 3 Entrance – Showing the permanent pile locations (red shading access route)

The Solution

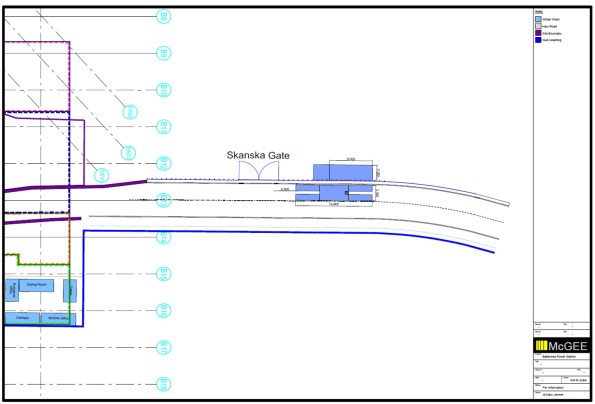

My previous blog discussed the requirement for collating detail from all stakeholders. Well, nothing has changed and once again a great deal of my time has been spent arranging meetings. This time it has concerned the interface with the other phases. I have spent numerous hours with McGee (Phase 3 ground works contractor), Bouygues UK methods team (from a construction phasing perspective), Skanska (Phase 2 Principle Contractor), Blu 3 (Phase 2/client’s ground work contractor), Keltbray (Phase 2 sheet piling contractor), Clipfine (BPS site wide logistics and security) and frankly a host of muppets from the clients side… The solution is shown below and as one can imagine this is not an intellectually challenging issue, nor is the solution technically difficult – the draining aspect of this managerial issue is dealing with a group of people who appear incapable of making a decision. It highlights the difficulties of project management on a multi-phased development and is potentially my next TMR.

I am sure you will all have thought of the solution – A single wheel wash directly procured by the client for all Phases but why this has not been done; only the muppets that I mentioned above can confirm!

Phase 3 Wheel Wash Location – in the final agreed position (hopefully)

Phase 3 Wheel Wash Location – in the final agreed position (hopefully)

Rich,

Sounds tedious but a key role pulling the decision makers together. Not that you need practice in getting disparate groups of people to come together to achieve something, a wheel wash in this case, but could be a business plan or engineering issue in the future, but it is likely to be useful managerial experience.

You cited things you don’t have, but if you have 120 tippers a day, that is some serious excavation going on, so there must be some interesting things going on in a hole near you. Has there been any attempt to validate geotechnical parameters? The great unknown ground conditions soon become known as you excavate so I wondered if anything had been rechecked or found out?

Out of interest, who has imposed a wheel wash on you? Say 3mins per lorry with 120 lorries is 6hrs of washing time. Other than it perhaps being deemed a sensible option, was a (or multiple) movable jetwash discounted? What are you doing with the waste water (any environmental concerns/permits required, water source issues)? As an alternative we had a road sweeper come and clean up after the tippers 3 times per day as typically they did 3-turnarounds each.

Presumably this is in preparation for a wet summer!

Doug, have you been chairing the meetings with the aim of trying to get the parties to agree to something or did you go in with an answer and attempt to use guile to get them to agree to it? In UKSPEC speak this is excellent C2 and D2 experience.

Any reason why the spare capacity on the NLE barge system couldn’t have been exploited as a win-win-win – your costs down and wheel wash gone, their cost per tonne down through third party utilization and additional revenue and London traffic reduced? I seem to recall Jonny noting that some other sites were going to potentially use the system which would help spread their overheads…

Where does the maintenance and operating risk sit with this solution? If it packs up and you put mud on the road because there is no alternate option, what are the penalties and who stands to foot the bill? Will schedule delays/costs be claimable against the client if there is delay introduced or emergency measures used? The old adage if you fail to prepare, prepare for failure seems to ring out loud. The fact that the physical solution looks simple and obvious hides the significant risks that might be being moved around. Have you looked at any of this?

Damo

You have picked up on a number of themes that underline why I described the client’s as Muppets!

The client dictated the requirement and (in my opinion) did not consider the repercussions that you have outlined (namely time but also space as Phase 2 must also maintain a wheel wash).

Water source and water discharge issues. Generally the problem is thrown back at us (the contractors) yet the solution requires a cross site approach – ie direction/guidance from a higher authority.

Rich

FLO have been (understandably) protective about their conveyor and although it may have been offered to Battersea – it was prohibitively expensive.

Risk lies with us and the only alternative is a jet wash into our own site but the client has offered us no drainage options…

Jim

We had the solution from the start as to be honest the location shown on the sketch was the only one that could work for all parties.

The tricky bit has been convincing the stakeholders whose starting point is not “on my site”.