One for the Cs.

Since arriving at the ‘New Perth Stadium’ I have spent the majority of my time on site – predominately to top up my ever improving glowing tan, but also coordinate an entire services install on a $1.4 Billion 60,000 all seater stadium. Last week, while stood in the middle of a disagreement (read massive punch up) between the blockwork and plumbing foremen, I noticed our mechanical air side contractor had started hanging fans and attenuators. See picture below.

This led me to ask a few questions – how heavy are these items? How are they hung? Were there any constraints? Weight limits? I also remember how poor concrete can perform in tension so thought I’d better act on my initial concerns and investigate further.

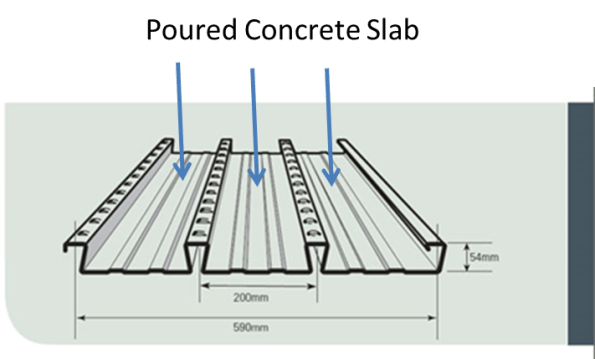

The current slab detail is simply made up of Bondek and poured concrete as detailed below:

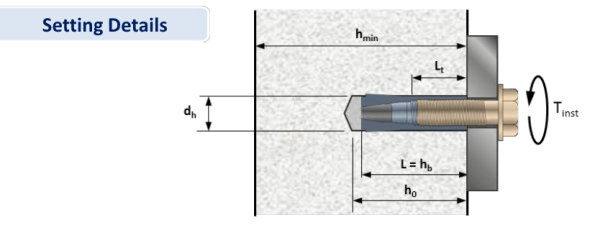

SOP for hanging fans involves drilling a 50mm hole through the Bondek and poured slab, before driving in a M10 drop in anchor which simply splits open at the top to provide a means of attaching a hanging rod.

So simple, even the E&M arm wrestling champion understands….Safe working load in tension for each item are published as:

Drop in Anchor – 3.4kN

Hanging rod – 10kN

Therefore if a fan is hung as per the photo with four anchor points, one could assume a weight limit of 1360kg. [(3400/10)*4]. Luckily (or unluckily) the Icelandic Arup Structure Consultant sits next to me, so I thought it prudent to confirm my findings before giving the green light to install 60 enormous fans.

His response didn’t fill me with confidence “go ahead and install the fans/attenuators which weigh between 200-300kg, heavier items may require secondary steel.” I AM YET TO GET THIS IN WRITING! This left me with further questions and additional concerns – not least how long is this steel going to take to design, how long before it is installed and who is going to pay for it? Services install is months behind schedule and I fear this issue is only going to compound our woes! What is more concerning is that I have no doubt that our mech air side contractor is ignoring all advice and hanging everything as fast as they can in order to knock off at 1430hrs. Welcome to WA. Best get back on site…..

Mike, have you also taken into account the Structural Adaquacy element of the Fire Resistance Level (FRL) for the hangars for those fans which are used for smoke extraction?

Hello Fran. The simple answer to your question is no. Better go speak to a grad.

Fran,

Does this mean you’ve come across instances when there’s an issue? I’ve never seen anything over than unistrut and threaded bolt being used for the hangers.

Rich, not exactly. It’s just depending on the zoning of fire compartments the threaded bolts will have to match the structural adequacy, usually 30, 60, 120 depending on the fire rating required for that particular area. So if the partition walls are 120/120/120 then the ductwork will usually need to be the same. So, a check against the fire rating requirements might be worthwhile especially considering the fans are going up and probably not all partition walls have yet? Has the fire engineering report, which explains the smoke and fire control strategy based on the fire compartment zoning, been completed by the designers?

There was a case at the Children’s Hospital where incorrect fire/smoke dampers were installed based on confusion over the compartment fire rating – so kind of similar thing could happen if the wall, mech and fire contractors don’t communicate.

Fran,

Fire rating for fire/smoke dampers, ducts and walls all makes sense. Is there such a thing as a fire rating for a hanger (presuming hangar was a typo)? Do I find it next to the tartan paint, long weights and sky hooks?

Turns out there is guidance:

http://www.statybosproduktai.lt/system/product_attachments/1638/original/PROMAT_Fire%20rated%20ductwork_katalogas_www.statybosproduktai.lt.pdf?1402847894

p196. Pretty sure I only ever saw M10 drops being used at Battersea irrespective of the fire rating.

Rich,

I know – that’s why I mentioned it. I actually used that very Promat article for one of my TMRs.

Mike, I suspect those capacity figures are related to the fixing’s capacity rather than the concrete slab. Therefore the structural engineer might have been concerned that slab was not designed for four 750kN point loads. I would have also thought there would be a specified minimum concrete strength for these attachments. Likely you are well passed the 28-day concrete strength so somewhere in a folder should be some cube results confirming that that slabs reached the design strength. It looks like common attachments to this permanent formwork system are lighter type fixings such as pipes and sprinklers. Therefore the secondary steel is certain to be needed – have the locations of the fan fixing points been specified? I assume so to align with the additional reinforcement.

Damian, you are correct regarding the fixing capacity – I am pushing Mr Arup for the minimum concrete strength for point loads, but continue to get washy answers. I assume other variables come into play such as people loading above, other services in the area and distance from the rib in the Bondek.

Fan fixing points are relatively flexible, so drop in anchors will move according to the location of the 2nd steel.

Mike, I understood from the foundation module that the idea is that there are specific fixings which dovetail into the sections of the Bondek which stick up into the concrete? Can anyone shed any light on this assertion? This looks like what’s been used for whatever’s hanging in the bottom of your photo.

If this is the case there is presumably a safe working load associated with the Bondek and fixings which should be a known quantity if installed correctly? It would seem pointless to specify such a system (I assume more costly) and then just drill straight through the steel? Unless the SOP has come about because the fan load exceeds the SWL of the Bondek.

To expand on Damian’s suggestion of secondary steelwork, clamping onto the structural beams would avoid the need for any drilling or cutting on site therefore reducing the H&S risk. That seems to be the preferred solution offshore for situations like this (obvs no concrete though, sorry civils).

Secondary steel is certainly the way to go – but there are in excess of 60 similar fans/attenuators/FCUs. It appears my initial observation is growing legs – I am currently going through a whole set of drawings to mark up mounting points for Arup to design 2nd steel… That should cover their all expenses Christmas party to Bali!!!

Mike if the issue is the point loads and not the UDL, can you not add additional fixings to reduce the point loads to an acceptable level?

Certainly something to consider – and one solution I proposed straight away. Apparently its not quite as simple as that…?!

Gary – yesterday’s cooling design meeting turned into the subject of cooled beams, you would have loved it. Designed in Australia apparently?

Mike,

I’m your blog you mention your golden tan. What products are you using to maintain/enhance this during the winter months?

How embarrassing, autocorrect has made me look stupid. My comment was supposed to start “In your blog”, rather than me declaring that “I am your blog”.