RAT or Scaffold?

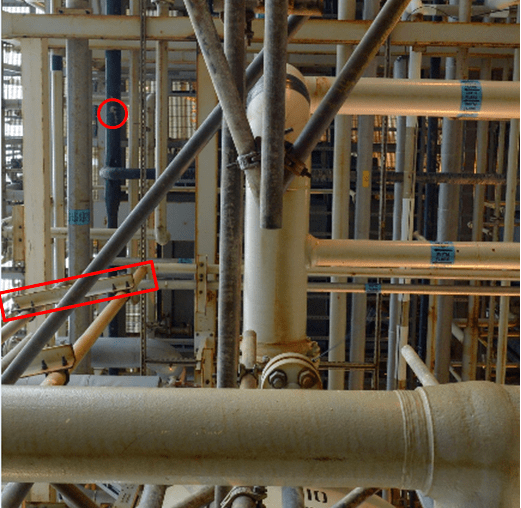

This time we’re on the BP Clair asset, West of Shetland, and the issue is access. Part of the scope of one of my projects is to install an additional 3/4″ drain line in the potable water storage system, in order to eliminate dead legs in which nasties such as legionella can lurk. Whoever designed the platform decided to put one of the drain valves 18m above the deck along one of the drainage pipe runs. The valve is circled in the below image (you’re looking straight up from the lowest deck level and the next deck up is the grating above and right of the valve).

Clair Drainage Valve Location

The new drain line will run down the support structure identified by the red oblong, with a valve at deck level so that the system drains from the deck through the grating into the sea. It’s potable water so we are ok to do that.

Getting to the valve is the problem. We can’t use a mobile access platform as such things just aren’t feasible offshore. So the answer is either a rope access team ‘RAT’ who, as the name suggests, hang off the structure on ropes to carry out the work, or build a lot of scaffolding.

The RAT are expensive due to their additional qualifications and training and there are added risks in terms of them dropping stuff and delay due to adverse weather. They are however quick and there is limited impact on platform operations or other projects.

Scaffolding greatly reduces the risk of dropped objects and construction delays but requires additional manpower and is much more time-consuming, doubling the offshore execution time. It is also very heavy and gets in the way; A few weeks ago the Clair platform stopped all non-operational work until all unnecessary scaffolding was dismantled and removed.

So what’s the answer? “Well it’s a balance between time and cost, what’s the client’s driving factor for the project?” I hear you respond. That’s exactly what I have asked the platform to decide and I’ll report back on the decison. Any views from the floor on a method of choice or similar experiences?

Sam, abseiling workers do come with additional risks to scaffolders, but as long as you do a thorough analysis of what these are, they are no more hassle than trying to build scaffolding in the middle of the North Sea. Dropped objects? Put catch nets in place and make sure everything is attached by lanyard to the workers. The only imponderable is the weather and I am guessing that building scaffolding is as badly affected by this as the abseilors. The only real difference in risk between the two that I can see is time to complete the task and cost. Which is the most important factor for the Client?

Jim,

That’s exactly my understanding and I have posed the question to the client. I’m meeting the job engineer from the vendor (who happens to be ex-RE, #win) and we shall discuss the options. It is likely that wind speed will limit the RAT in the same way as cranes are on land, but unlikely to affect scaffolding. An interesting development is blast. I was informed yesterday that the Clair platform is an ‘open’ design, i.e. all floors and ceilings on the production side are mesh gratings to limit structural loading in the event of an explosion. Not quite as effective if you fill all those nice gaps in with scaffold boarding…

Sam, from what I read it sounds as if the RAT team are the way to go. I assume that there are savings on the transportation of the scaffolding to the platform. The picture from below looks extremely busy from below. I assume that if the scaffold would be from the left side of the picture?

I have found here that making a decision even if you can break it down to cost vs time etc is hard to get out.

Jonny,

I’m leaning that way as well. Apart from the obvious inverted crow’s foot in the picture, anything that looks like a galvanised scaffold pole, is. This shows just how complicated fitting in scaffolding would be. Luckily offshore there is lots of exposed structural steelwork to clamp onto. Additionally BP use a single scaffolding vendor across all North Sea assets so the crews will be familiar with the platform and have probably put up similar scaffolds several times before.

Sam,

I’m with Jonny and Jim – VOTE RAT.

If the job was bigger and more complex then I would probably say the scaffold offers more flexibility and access. But given it is a small job then time and effort saved using RAT must trump the additional risks of RAT. And as Jim points out, the risks to the RAT from weather and the impact of dropping items can be mitigated.

VOTE RAT!