Conveyors, Controls and Carousels

Confusingly, no-one has taken up my offer of talking airport baggage over a coffee here from my last blog. So, I thought I might give you all an update on one of the Gatwick Baggage projects; it might entice some of you sitting on the fence to come and find out some more first hand.

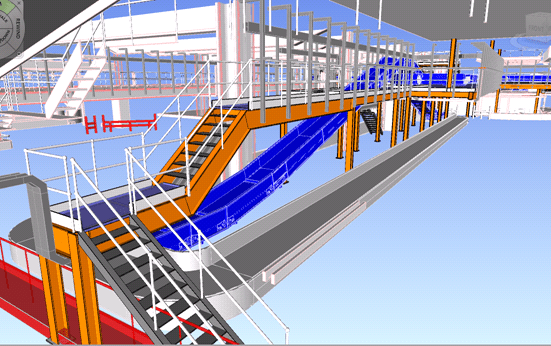

The first project in the programme has now gone into construction phase, with the final design hopefully appearing something like the model below. This is an £8.1m project and, as an enabling project to the remainder of the £140m programme, must be completed by the end of the year to avoid significant knock on delays to the programme.

This structure is a new ‘Make up Carousel’ and consists of two new conveyors feeding a new carousel. This is the same as the baggage carousels that you will have picked you bags up from when you arrive at an airport, however in this instance, the bags have just been screened for explosive threats and will be loaded onto the aeroplane for departure.

The majority of items in this view will be new works, of which most will have to be completed in the daily window between 2300hrs and 0330hrs when the airport is non-operational.

This is the first project that Gatwick Airport, as a client, have tried their ‘package management’ approach. This involves the client taking main contractor responsibility and contracting directly with discipline sub-contractors (Structural, Civils, M&E, Controls, IT and Baggage Systems). In theory this will allow greater control and reduce project risk, though it is proving a steep learning curve for Gatwick, particularly in terms of mechanism for design collaboration between the discipline contractors. Any thoughts from other sites / design offices on approaches used by other main contractors to this would be appreciated.

Getting everything in writing. Our lead designer unnecessarily reworked an electrical design and claimed I had instructed it. When I queried, it turned out the only reference they had was a supposed telephone conversation that I don’t think took place – nothing in writing so no costs for the work incurred thankfully.

Working outside of permit. I think an honest mistake, but the M&E Contractor I am responsible for managed to complete some electrical works outside of their permit to work – on day three of being on site! Cue stopping works and incident report submissions. Not a great start for the contractor.

And finally, as the summer rush arrives and the number of stag and hen parties in the departure lounge peaks, the baggage handlers seem to be competing to see who can throw passengers’ bags the furthest when packing their baggage trollies. I think the informal record is about 4m – perhaps best not to put the bottle of chablis/ouzo in your hold baggage!

Sounds like it is all going in to a pretty tight deadline big Stu… have you got any pics of the current area or does security stop you taking photos?

I don’t like the sound of those working hours. When do the night shifts start for you Stu?

I’ll get photos of the current area in the next blog Mark; imagine a double height multi story car park, with the baggage tugs zipping around and you’re not far off.

As for night shifts, expect I’ll get a few in October, though I am pushing the contractor to do as much as possible off site, with minimal works during operational hours. All electrical isolations will have to be at night though, and I wouldn’t want to miss those.

Stu,

The package management sounds like a bad idea to me, unless Gateick have specifically recruited a specific project team with the necessary experience. It sounds like something the Army would do – a plan that minimises additional resources, saves money and adds to everyones’ work loads. I hope I am wrong and being cynical, but I’m not sure a £170 million pound project on critical infrastructure is the best place for Gatwick to start.

Also, if you can’t take any photos of the baggage area, any chance of photos of amusing stag/hen parties?

Granty, To some extent I agree, however the driver is not money or resource reduction. The driver is reducing delivery risk by permitting closer engagement with the discipline suppliers by the Engineers and Project teams within Gatwick.

Like you say though, it requires particular experiences and skills to manage the sub-contractors and the past two months have been a steep learning curve for the Programme team. Using a Main Contractor starts to look increasingly attractive…though not so good for my key competencies…