BIM induced delays

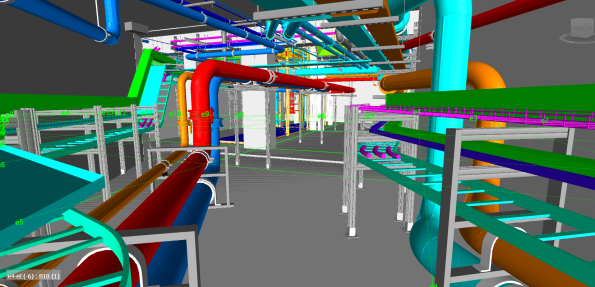

I am responsible for the fitting out of a basement area and so I am trying to sequence the works, using the BIM model to decide the order in which stuff needs to be installed. As such my works programme is becoming pretty complex. Here is a 3D BIM model of the area I have to fit out including all pipework, ladder racks, trays, ductwork and basketry. This task will involve the management of six separate sub-contractors and their interfaces.

BIM is a great tool but very slow and I am finding that the constraint on when I can start each work package is not the supply of materials or availability of sub-contractors but rather the production of construction drawings. So now we are at the point where the drawing production programme is driving and dictating the MEP programme. Due to a lack of coordination at the start of drawing production, the drawings are not being produced in the sequence of construction, causing further delays in several areas and messing with my programme. We have now coordinated with the BIM Team and created a drawing sequence that better reflects what we plan to do on site.

Is this issue unique to our site or common place where BIM is the primary driver of the Building design?

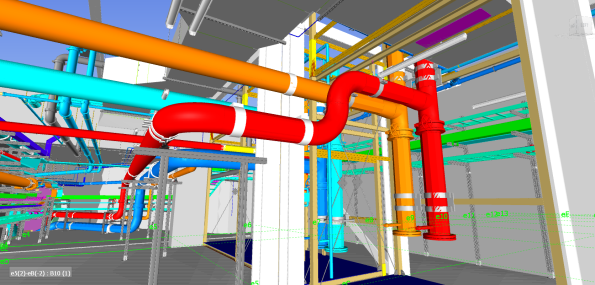

Here is another pic of the basement area showing the complexity of the task:

Sadly, I will not be able to finish the fit out of this area before departing the project and so will not be able to install the whole of the ductwork, smoke extract system, fire alarm system and most of the cable racking.

Gary,

Did you find BIM as a process/methodology slow, or do you mean the software package you are using is slow? Also if design drawings are the issue then surely contracting in addition resource in terms of design draughtsmen would mitigate the far more costly issues of delays and service clashes downstream?

Sam, the process is slow because it involves designing in 3D then replicating in 2D and also getting changes signed off by the designers. To make it worse, CAD draughtsmen are either 3D or 2D and so each job requires two people. Also we have a developed review strategy here that means all drawings and designs have to be fully reviewed and signed off at the 30%, 60% and 100% stages. Also a high turnover of BIM managers (due to struggling with the work load) has added additional delays.

We have a site wide shortage of BIM modellers and 2D draughtsmen and despite a surprisingly highly salary (£250 per day for 2D and £350 per day for 3D) we struggle to recruit additional staff. I believe this shortage is common across all of the Skanska projects and so they can not surge manpower from another project. Each team within the project has its own BIM team – although there is only one large merged model – which means we can move people around the project internally to maximise productivity in key risk areas.

I’d get all the grey bits done first 😉

Gary,

I am encountering exactly the same issues here.

Since earlier this year, Gatwick require 3D modeling for all design, however the supply chain is still BIM immature. Whilst subcontractors with design elements in their package are able to generate designs in 3D and ‘slice’ 2D elements for traditional design review and coding, the integration across subcontractor’s designs has been problematic with miss-understanding about methods/software to be used has caused significant delays to design stages. This has led to construction starting with final designs not yet approved, in order to prevent programme delay.

Similarly, BIM manager turnover is also high. When I asked the last one why he left, he essentially stated that it was because no-one was really interested in it or listened to him, but that his workload was enormous as everyone had to tick the BIM box for projects.

To answer Sam’s point, decent BIM resource around this area (just outside of London) is difficult to come by – or maybe Gatwick should just pay more??