Dealing with Delays

The pace of work is speeding up as I reach the last month of my phase 2 attachment. Excellent news *insert sarcasm*.

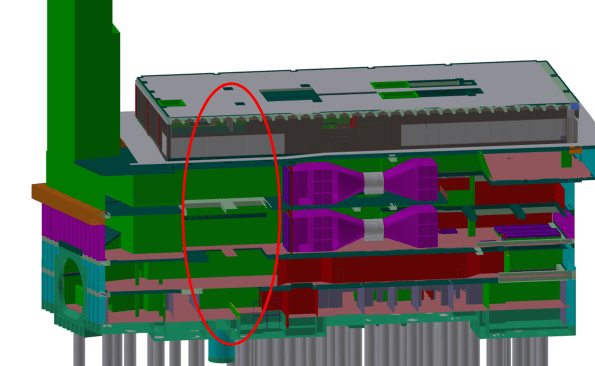

The finished Bond Street East shaft structure should now be complete to accept tunnel ventilation equipment; cut-away graphic shown below.

Graphic of the station structure; the ventilation equipment is shown in purple. The red oval denotes a gaping hole currently being filled by the civil contractor (see next photo).

The station structure was due to be complete by Aug 16; however the current site still has no roof, no lights, unsealed walls, etc; as shown in the figure below.

Tunnel vent fan room, missing the end wall (see previous image) and some weatherproofing, paint, permanent lights, etc….

As a result of this delay the mechanical install (by ATCjv, my placement company) has to happen concurrently with the remainder of the civil works to make sure the trains can start running on time. The past few weeks have therefore been dominated by ‘collaborative planning’ to mitigate the civil contractor’s delays. I have eaten through a couple of packs of post-it notes and a lot of coffee to achieve an integrated 8-week plan that both sides agree on, see below:

This is all to achieve an interface control document (ICD); a kind of access and working contract where ATCjv mechanical works are installed in another contractors site Prime Contractor (PC) area. The process has also been a contractual minefield as the ATCjv works information assumed we had uninterrupted access to the entire structure.

The handover process should follow these steps:

- Civil contractor finishes structure.

- ATCjv accept structure and conduct a condition survey.

- Both sign an ICD and ATCjv start installing mechanical ventilation kit.

The actual process has been:

- Civil works delayed by >5 months.

- ATCjv have to start install to achieve Crossrail opening date, 2 weeks of collaborative planning commences.

- ATCjv rinse Crossrail (the taxpayer) for compensation events. ATCjv hide all their delays behind the civil contractors problems.

- ICD signed and mechanical install starts

It has not felt comfortable knowing that I have been part of the dodgy contractor game of blaming all our problems on a third party and getting a wedge of extra money out of the client/taxpayer…. welcome to construction.

On a brighter note we have achieved actual mechanical installation at our Tottenham Court Road site; one gantry crane installed and commissioned on programme. However, I can’t help but feel out-done by the size of Jo’s man-size crane.

Mark,

I think you’ve brought up a good point here, and one that I’ve seen on my own site too. There will inevitably be clashes when the situation changes and contractors have to manage time and space. To supplement Doug’s post about things for the phase 1s to take into phase 2, I have found that we are far better at this “Battlespace Management” than most of the management on site, and taking on such a task is one way to make a good initial impact. With a slight tweak to the terminology this can be managed with ops boxes, manoeuvre corridors, restricted fire zones, reporting lines……….

A word of warning to the Phase 1s though – this can be quite time intensive and once you’ve done it for a few weeks you’ll cease to see any extra benefit, so make sure you have an exit strategy and don’t get stuck in this role too long like I did.

I would definitely agree with the comments about BM. It seems that industry conducts BM poorly and I have found my previous experience as a battlespace manager to be incredibly useful. BM offers PET students a great opportunity to impress and add value on site. Introducing formal ways of recording responsibility for site areas and explaining how these relationships can managed is an easy win for us. In addition to BM, command relationships is another area which suffers in these situations and I have found construction CMs giving instructions directly to my MEP subbies. Again this is an area where we have a lot of relevant and value experience and can make an impact.

I agree with the above… However all co-ordination then needs to be instructed or written into the works info or contracts for the various parties. It has been easy to get carried away with doing this kind of work only for the subbies to ignore it because it wasn’t written into their contract.

BM = Brookfield Multiplex? I have been away from the Army too long.

Tony funnily enough I did a lot of this during my excavation phase. I didn’t think of it in those terms but you are spot on. It is a good way to establish instant credibility though as it really is second nature to us.

Your last couple of lines are quite important Tony. The risk, as you identify, is getting drawn in to doing what any army officer could do well and not gaining the practical engineering knowledge and experience you require. By all means use these skills to earn trust and respect but then cash that in for the experience earning opportunities you need.

Mark, I am in the same boat as you. My project is delayed by 6 months with some packages probably delayed by a total of 12 months! We are doing parts of the install concurrent to the construction work which adds a surprising amount of complexity and forces me to liaise with my construction counterpart 5-10 times a day. It has made the programme very messy and nobody really understands how individual elements relate to each other in the wider picture and exactly where the critical path lies. I can imagine this problem is exerbated ten fold when the construction team and MEP team work for different companies.

However this situation does offer some opportunities for value engineering such as loading plant into an incomplete structure or fitting pipework into confined spaces before they are enclosed/confined.

It is worth mentioning for the E&Ms that delays will always be felt harder by the MEP team and one thing to constantly review is the supply chain and delivery dates. We had issues with large plant being ordered at the start of the year for delivery now but delays prevent it being received on site. However these delays have not been effectively communicated to the supply chain and so we are now having to pay for storage of items that have been manufactured – something the client isn’t happy about! So I recommend developing a supply matrix for your packages and list the latest date at which the order can be put on hold and regularly review it.

Mark,

I think your issues are alarmingly common. Despite significant delays to areas of the structure the M&E team on our site are under significant pressure to get started even in areas where it is not practicle/feasible or as safe as you would hope. This is all due to the fact the delay cost to the main contractor is an astronimical amount each day! We basically have the civils and M&E team now fighting each other in the same areas as the pressure mounts. I’m beginning to understand why, even with minor programme delays, making money on construction projects is a very challenging endeavour, particularly on a circa 4.5% profit margin.

Very similar experience down under too. I tried managing a delayed structure by introducing a 4 week look ahead for service sub-contractors – basically who should be working in what area and when the builder expects them to be finished. It was wasted effort!

I agree with mark, unless it’s written in their contract with a signature from god some contractors will continue to work where it best suits them. Those that did play the game lost out.

What was even more frustrating was some of the construction sub contractors clearly wielded far too much influence. It was almost like they were untouchable and got away with poor workmanship, straying off programme etc… I believe this comes down to where Perth is – most isolated city in the world with limited firms with the capacity to complete a project of this size so the big fish exploit the builder. 😳