Managing Temporary Works Risk

As most students will have noted on phase 2, TW can be a particularly high risk element of any construction project. For the last few months, in addition to my other responsibilities, I have been involved inspecting items as they are installed and during their ongoing use.

On a high rise building, a failure of TW in an unfortunate location can have exceptionally serious consequences, because people or items can potentially fall from very significant heights. As the Principle Contractor we are therefore supposed to provide a very thorough secondary control system. This involves scrutinising and inspecting the TW’s designed and installed by our relevant sub – contractors, who officially carry liability for their own systems. I have noted that more often than not TW are not installed exactly to the approved design as the guys on site have a habit of making unapproved adjustments. Whilst this is not acceptable, in many cases the implications of a failure are minor.

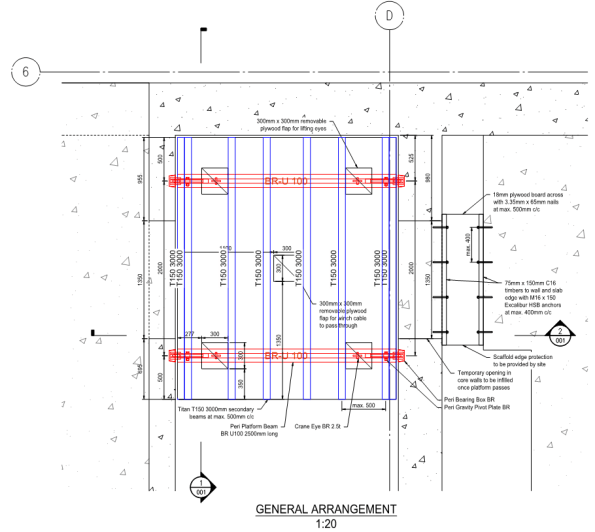

This morning whilst conducting a check of a TW system installed by our concrete contractors a colleague and I identified an issue that worried us significantly enough that I have decided to write a blog on it. The images below shows the design of a temporary access walkway platform suspended between two walls of our reinforced concrete core. It spans over a permanent lift shaft at level 10. To be clear, below this TW structure is a 10 storey, plus 15m of additional basement, vertical drop. i.e. If it fails and someone is on it at that unfortunate moment, that person is falling unobstructed down a vertical shaft for the best part of 32m, from floor 10 into our basement.

You can therefore probably understand why I got very upset when it became apparent (whilst I was stood on it) that this system had been installed, declared operational and used by numerous operators on site without the most basic conditions being met:

- The design process being completed in full with a final check signed off as status A by MPX (Principle Contractor)

- The installation being inspected to assure conformance with design by a competent MPX TW supervisor

- A permit to load certificate being signed by a competent person

It turns out they built this over a weekend and started using it immediately without anyone checking the quality of the installation. Even the sub-contractors own TW supervisor (The first layer of inspection) had not checked and signed off this installation prior to its use. In this case two of the key management safety layers had been completely ignored; highly upsetting when you consider that a failure of this system would almost certainly result in a fatal accident.

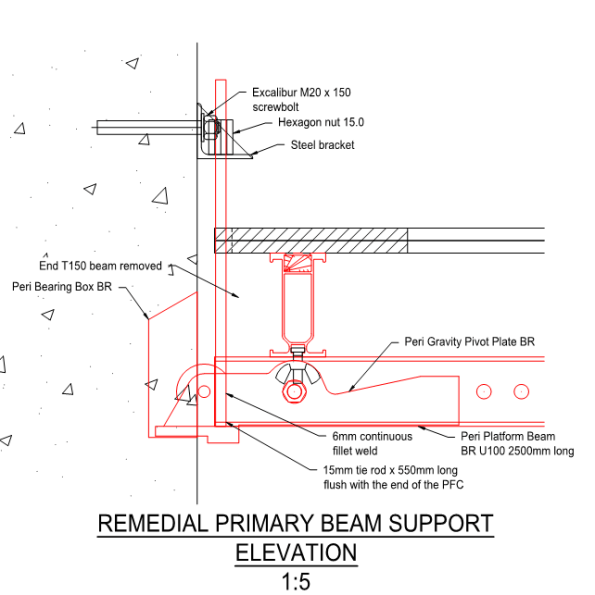

The TW platform prior to the installation inspection – Structural components cannot be easily accessed or inspected

TW Primary and Secondary Beam Installation Check

As the images above show, in this case we were eventually able to access the TW structure and confirm it had been installed correctly. Our main issue is that this process did not proceed us standing on it over a lethal void.

The TWprocedure exists for a very good reason. To provide multiple layers of review and inspection in order to best mitigate the risk of a failure and a subsequent accident. It is quite alarming how often sub-contractors prioritise programme and task progress at the expense of a thoroughly enforced, critical safety procedure, particularly on such high risk TW schemes.

Tom, I am not in the slightest surprised that this has occurred, especially after weekend work. During my time with Expanded I encountered similar issues. Primarily deck control sheets. The site had numerous Peri decks which would be loaded with stores (large amounts of rebar!) the moment it was erected. The supervisor for that area was responsible for ensuring that he had signed the deck control sheet to confirm that the TWs had been checked and it was safe to load. The site engineers were meant to monitor this process. However, nearly every week the project manager would raise the issue that these sheets were not being filled out and that “if there is an accident, we have no leg to stand on”.

I completely agree that Sub-contractors will prioritise programme. Whilst they are not prioritising programme over safety deliberately, there is a lot retrospective checking to show that something which is already loaded can be loaded. I found a lot of the time that the speed of construction would often out pace the paperwork train and no one is willing to pause construction to let the paperwork catch up. It is all done at a later date.

I may be wrong but I think there is an art to writing checking procedures so that they are adequate and get done rather than perfect yet ignored/handled in catch up. I’m not saying this was the case here but the regularity with which ‘doing the paperwork’ is seen as a necessary evil to be done before anyone complains/notices rather than as an aid to safety, welcomed by all, appalls me. Is it possible that the fact that it is not immediately apparent that the TW have not been checked and paperwork is a pain to chase up are contributory? Would a spray paint marking with inspection number make it clear to all that TW checks were complete? Might this make it more obvious that everyone is taking risk without it? Any other thoughts as to how this might be tackled as a cultural issue?