Archive

Rock blasting in the middle of the city!

Blasting next to a heritage bulding in Fortitude Valley, Brisbane City

So I am currently assessing how to build a 4 m basement car park in a swamp with a CBR of 1.5. I could go into the details of that but, while researching my thesis I came across these videos of blasting in two of my case studies Fortitude Valley and 300 George Street which are far more interesting. How do you get away with blasting very hard rock in the middle of a city? With a lot of careful planning. Note the mattresses to prevent fly rock and the drilling before hand in the 300G video not just for placing the explosives but to localise the effect of the shockwave

Details of the blast

Building Energy Efficiency

How do MEP engineers design a building for energy efficiency? This was a question that had often kept me awake at night…. fortunately thanks to the first few weeks at a design office I have an idea of how the process works. This blog will briefly run through the process of designing the building MEP to specify equipment and meet the UK energy efficiency (Part L) building regs.

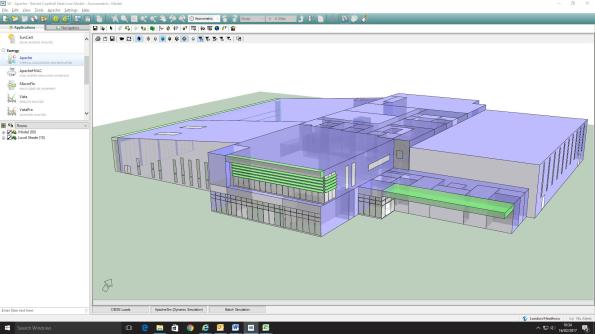

Building thermal model in IES – Hevacomp for grown ups

First of all some principles of how the design office operates (so far):

- Minimise time. Time is money for the design office; they are very fastidious about budgeting time to a project in advance and accounting for the time spent. Therefore only the minimum design work is undertaken. g. pump size on the longest pressure drop, don’t both with checking anything else.

- Deliverables drive the project. In conjunction with the previous point; Bryden Wood will only produce a model when they are required to do so, otherwise Excel is generally used to do the job. In my first project the client has paid for a Revit model update every two weeks, but all equipment sizing is done on Excel. The data in this model is minimised to limit time wasted; for example pipes are shown uninsulated as it would take time to draw it on, drawings are not colour-coded, etc.

- Energy Efficiency Legislation is met (just). There is no advantage to the client of smashing the energy efficiency legislation… this would just waste money. The equipment and building materials have been spec’d to meet the legislative requirements and no more.

- Minimise Responsibility. The MEP team is only able to influence a small element of the overall building performance; designing MEP equipment. Unfortunately we are required to predict the entire building performance – which is influenced by the number of windows (architects), orientation (arch), structure (civils), etc. Therefore time is spent recording other stakeholder’s decisions to protect BW if/when the building fails the performance checks.

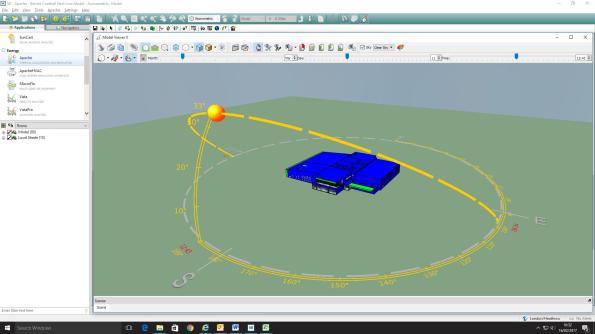

Sun path graphic for Barnet leisure center. The program will include solar gains for rooms.

My first project has been the MEP fit-out of two leisure centres in North London. In very simple terms the design process has been:

- Develop Strategy. A scheme for the MEP design is developed based on building use and client wishes. This is generally based on experience within the design office and the clients’ spec; for example the swimming pool will be served by an Air Handling Unit (AHU), Café will have underfloor heating, etc.

- Rough Equipment Sizing. This is undertaken on a big Excel spreadsheet with details of temperatures, room internal heat loads, fabric losses etc. All very reminiscent of the PEW design exercises, based on CIBSE or ASHRAE references. Loads are summed (with a bit of fudge factor diversity) to give approximate plant loads for the building.

- Select Manufacturers. The client has a list of preferred manufacturers who get involved with selecting the equipment for role based on the rough loads calculated above. This stage has an element of project management to it, and a few free lunches.

- Develop Thermal Model. Dedicated Integrated Environmental Solutions (IES) software is used to model the thermal characteristics of the building, in parallel to stage 3. This adds more accurate numbers to allow detailed plant sizing and includes solar gains, heating profiles, etc. The full potential of this software is not used to save time – for example, instead of modelling the transient (or warm-up load) for the building the equipment is sized on the steady-state load +15%!

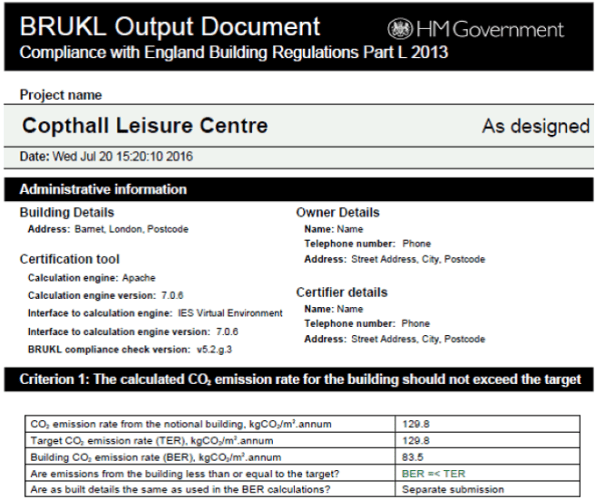

- Confirm building meets Part L. The IES program is one of four approved to determine whether a building will meet the legal efficiency requirements. Detailed system information is added once plant has been selected, then the program produces an Energy Performance Certificate (EPC) and Part-L compliance certificate.

The finished Part-L compliance report

In all this process will have taken a team of three about 12 weeks to complete… a bit more relaxed than the single week we are given on the building services design exercise at PEW.