Archive

Reduce your Embodied Carbon!

In my previous blog, I mentioned I would be involved in an Embodied Carbon (kgCO2e) study to be completed retrospectively on Gatwick’s newly finished Pier 1. Here are four generic recommendations for embodied carbon (and cost) reduction that could be applied to any construction project.

Useful to those currently in design offices writing design specifications and those going into phase 2 who might influence materials specs – some of these are a great way to save your client money, helping them to meet embodied carbon reduction targets, whilst providing perfect evidence of achieving UK SPEC competency E3 – ‘Engineering in a way contributing towards sustainable development’.

They may demand a broadening of the mind of clients / design colleagues to gain agreement!

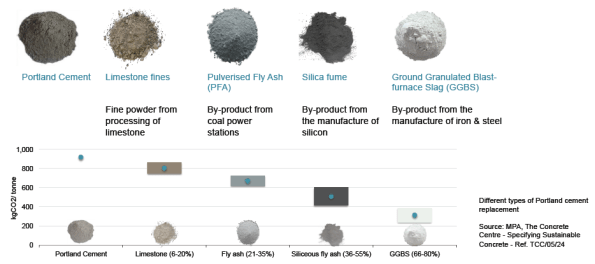

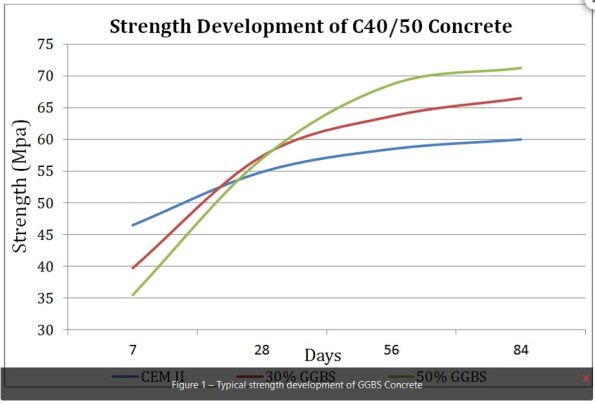

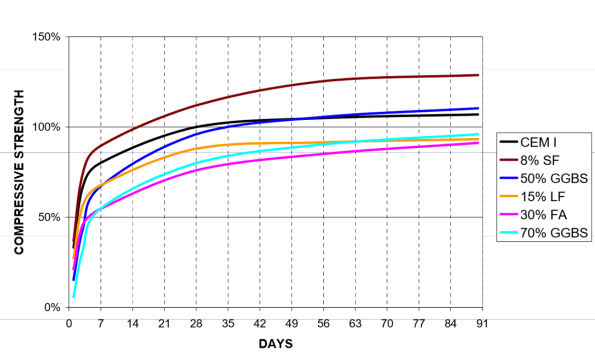

- Replace up to 50% of cement content of concrete with Ground Granulated Blast furnace Slag (GGBS): (the civils will know more about strength implications and codes for this but BS 8500 gives the guidance on tolerances).

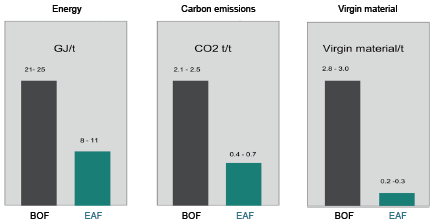

- Specify Electric Arc Furnace (EAF) steel (up to 100% recycled steel) over Blast Oxygen Furnace (BOF) steel (up to 30% recycled steel).

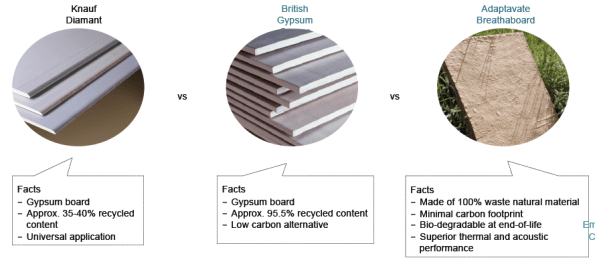

- Consider natural materials for internal building fabric. Caveat to this is that the ‘adaptavate Brethaboard’ below will require thicker plaster finish skim than the other two. Other alternatives products exist using natural clay which can absorb and release moisture into internal space, thereby passively regulating humidity.

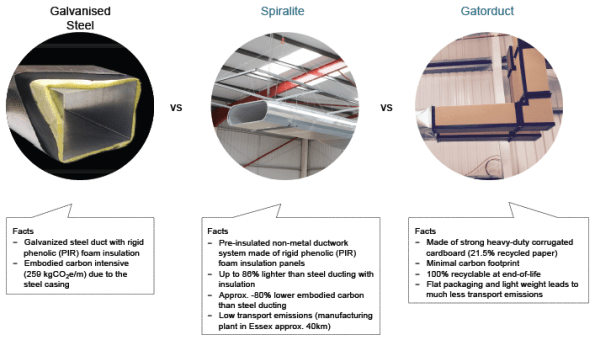

- Replace traditional steel ductwork with alternatives. To me, this might be the most difficult to get agreement from a client familiar with steel design going in and indeed steel ductwork is the generic requirement for all of Gatwick’s HVAC systems. However, in certain situations, such as relatively short lifespan / high turnover retail installations, the Gatorduct might be an better option.

I’d be interested if these types of products are commonplace on other sites indicating that perhaps Gatwick’s construction department remains too traditional / slow to catch up? Or maybe just meeting programme drives designers / contractors to stick to what they know?

Slides to go with Tom’s reply:

Defects in Melbourne Fitout

I am currently working in the “tenancy team” at Norman Disney and Young in Perth CBD. The tenancy team completes small scale building services consultancy fit out projects in a short period of time – usually a couple of weeks from start to finish.

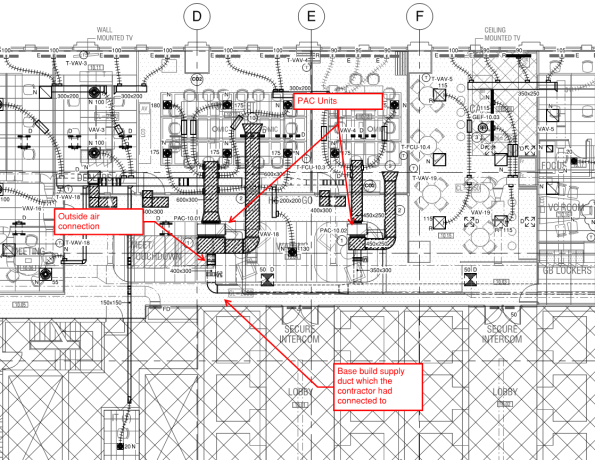

Amongst several other small projects, I have been given responsibility to consult on the mechanical construction phase of a HSBC tenancy in Collins Street, Melbourne. During the commissioning phase, a colleague of mine in Melbourne compiled a defect list, which happened to be extensive and include a number of concerning items. Given the tight timelines, by the time I received this document, users had moved in and started operating in a functional office space. One defect in particular was alarming – the mechanical contractor had connected outside air provision for two packaged air conditioning (PAC) units to the existing base-build supply ductwork. This presented a series of problems:

- Insufficient outside air provision to the two main meeting rooms.

- Imbalance of the existing base build system.

- Conditioned air being introduced to return air in the PAC mixing boxes.

To make matters worse, the client has unsurprisingly received complaints from the users – half complain about being too hot, while to rest are grumbling of being too cold. As the proverbial rolled down hill in my direction, I was asked as the mechanical design authority to rectify the situation. Both the builder and mechanical contractor were naturally eager to shift responsibility to the mechanical design, when in fact the system had been installed incorrectly. After an afternoon of rather animated phone calls and meetings, the mech contractor is now starring down the barrel at removing office users, taking ceilings down and installing the ductwork correctly. And rightly so! Understandably, both the builder and contractor were set on blaming the consultants design and I had the pleasure of going through the system design calculations with both parties. Luckily NDY’s design and quality assurance for this particular project was thorough and correct.

See Mark up attached.

I am somewhat surprised that the builder/ project management company allowed the user to move in before all of the defects had been addressed. Additionally, the original commissioning results are incorrect, invalid and wrong. To that end, I am pushing my project leader to request a re-test by the mech contractor – with a perhaps a young, enthusiastic, British engineer in attendance 😉

Update – Picture for you Fran.

xx