Archive

The Stage

I have started my Phase 2 attachment with Brookfield Multiplex (MPX) as what seems to be a site engineer and construction manager on The Stage project in Shoreditch, London and I want to provide an overview of the project and site to allow future blogs to relate to it.

Location

As can be seen from the picture below, the project is within drinking distance of “The City”. It also sits next to two other MPX sites, Principal Place Residential and Principal Place Commercial. There are also numerous other projects going on within the immediate vicinity making for a very congested area of London. It also means that some of the MPX staff (mainly H&S and QS related) are cross-decking between the projects, splitting their time between the sites.

General

The development is a mixed use scheme comprising of a 37 storey residential tower (building 1 – prestressed concrete), a 14 storey office block (building 3 – steel frame), and a 9 storey commercial and retail block (building 2 – prestressed concrete). In addition to the three largest buildings there will also be a performing arts pavilion, heritage centre, sunken amphitheatre, popup retail units (to hide a dated masonry substation) and the conversion of former Victorian rail viaducts; and all to be done to a BREEAM excellent standard. There is also the preservation of the remains of Shakespeare’s Curtain Theatre which date back to 1577. These remains are of international significance and are being preserved as the focal centrepiece to the development, hence the name.

Contract

The project is currently in week 19 of 20 of a Pre-Contract Service Agreement (PCSA) and conducting early works using a JCT D&B contract between the Client and MPX. I will be spending some time with the contracts team to better understand how this works commercially. The background to this is that Gilliard Homes (the Client) originally started the project themselves and stopped it when things weren’t going to plan, then they appointed MPX as Principal Contractor. They wanted work to happen quickly which is why a final contract for the project hasn’t yet been established. What this means is that there are legacy issues on site caused by the work conducted by Galliard Homes. For example there are some incomplete secant wall capping beams in place of which Keltbray, the main contractor on site, cannot guarantee the structural integrity of and will have to demolish. There are also existing utilities which the Client had previously moved from outside of the hoarding, which now lie in the way of the secant pile wall design. This requires the UK Power Network (UKPN) and BT to be involved to move the utilities before the secant wall is constructed. All elements resulting from the work conducted prior to MPX result in a risk being carried by the Client.

Current state of site

The site is currently in week 11 of 50 of early works, incorporating secant pile walls and bearing piles before excavating about 18m to allow for a bottom up construction. There are 2 x 90T piling rigs on site with respective cranes, working on 1m thick piling mats. The ground is being excavated from +15m AOD to +11m AOD before props are installed to allow further excavation. Another important aspect of the project is the presence of the Museum of London Archaeology (MOLA), who are conducting archaeological digs on site. We were taught that archaeological finds are likely to cause a significant delay to a project. However, it is a key part of the brand of the development and MOLA’s digs are being facilitated by MPX throughout the project and time has been put into the program to allow for archaeological overruns. The only finds being preserved are those of the Curtain Theatre which dates back to 1577. This has been fully excavated and has since been covered using polystyrene, steel plates and some very expensive aggregate. This means that the area under which they lie can be trafficked and used for stores. The presence and exploitation of the archaeological site and its future use as a major tourist destination means that the development does not need to incorporate any “affordable housing”. There are also other archaeological digs being conducted on site but these will all be recoded and removed by MOLA.

Piling methods

Currently there are bearing piles and secant pile walls using guide walls being constructed. However, I noticed that contiguous piles were mentioned in the H&S plan. This will be a subject of another blog. In the meantime the piles here are CFA using polymer (polymer plant in the picture is hidden by the blue ISOs). You can hear the suction from the London clay when the auger is removed from the casing. I will also see the first of the plunge piles being constructed in the next few weeks. I will do a separate blog about the history of the soil in this area of London as it has some good historical background.

Key constraints

Hackney Council have a number of restrictions to the site, the first of which is the working hours. The site is limited to weekdays 0800 – 1800hrs and Saturdays 0800 – 1300hrs. This means that the piling has to be at a practical stage every day to finish at that time. Any over-size loads are only allowed to be delivered overnight or at the weekend. There are no actual sound limitations imposed on the site so the project has a self-imposed noise limit of 78dB, which is the average noise level measured from the city. A full pre-construction survey was conducted of the surrounding buildings and their movement is being monitored. Of interest is the tilt monitors installed on the listed pub at the western edge of site. I note that the monitor recorded 6mm of deflection at 2030hrs last night (everyone had left site by then), correlating with the pub opening times. It has also been noted that it deflects by similar amounts when the beer is delivered to its cellars. Every time a monitor, whether sound or tilt, is triggered it is automatically logged on Information Exchange (software) and a report is to be filled in. That, in conjunction with the pre-construction survey, are used to establish whether the site causes any damage to surrounding buildings.

Another building which forms part of the site boundary is a 1950s masonry UKPN substation which has already been damaged by the back of a bucket when a subcontractor broke from an agreed method statement, an issue of non-conformity which has all been resolved. It is being closely monitored for movement as it apparently supplies electricity to half of the city.

Issues

Live substations. There are currently 2 live substations on the site which require temporary substations for the duration of the project. The installation of the temporary substations and the removal and decommissioning of the old has already involved a lot of interaction between subcontractors and utilities agencies. It has been interesting to see how the interagency interaction is managed by the MPX team and has been the basis of me learning how MPX operate on the site.

Site accommodation. The site accommodation was inherited by the work done by the Client previously and is deemed inadequate for MPX. Its size and location is critical to the project’s progress and the responsibility for its implementation have been given to me. In the short term it needs a temporary expansion in its current location to cope with an increase in the female workforce, to coincide with MOLA increasing their numbers in June. In the medium term a 4 storey 40m x 12.5m modular temporary accommodation block will be built on a concrete slab still to be constructed on the southern edge of site. This will house approximately 1200 personnel and will be complete by November. Following this the existing site accommodation will be refurbished and expanded to facilitate the latter stages of the project when the personnel reduce and move out of the 4 storey block. I have now been given the responsibility of this site accommodation project and have mid tender scope if works meetings with two suppliers to discuss the options next week.

Office politics. The main construction manager has resigned (on my day 3) after being on the project 9 weeks. This means he only has to give 1 week notice and will be leaving next Wednesday. It would appear I am now mid handover/takeover with him, hence the site accommodation project switching to me. I have already seen there is a case of office politics, largely based on personalities. It will be interesting to see how this progresses and how it differs from what we are used to. It may stem from the project office being dislocated from the site office by a few streets; naturally I think this causes a bit of friction between the two.

Summary

This blog covers an overview of the project and an experience of my first week here. It provides a starting block to help orientate future posts about the project and gives a rough idea of what will be involved here at The Stage. Meanwhile I will come up with various ways of getting Shakespeare into future blogs.

Reduce your Embodied Carbon!

In my previous blog, I mentioned I would be involved in an Embodied Carbon (kgCO2e) study to be completed retrospectively on Gatwick’s newly finished Pier 1. Here are four generic recommendations for embodied carbon (and cost) reduction that could be applied to any construction project.

Useful to those currently in design offices writing design specifications and those going into phase 2 who might influence materials specs – some of these are a great way to save your client money, helping them to meet embodied carbon reduction targets, whilst providing perfect evidence of achieving UK SPEC competency E3 – ‘Engineering in a way contributing towards sustainable development’.

They may demand a broadening of the mind of clients / design colleagues to gain agreement!

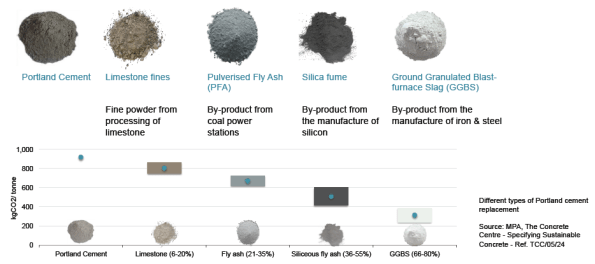

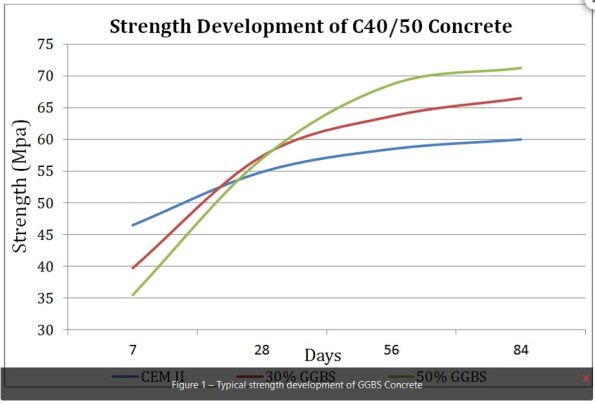

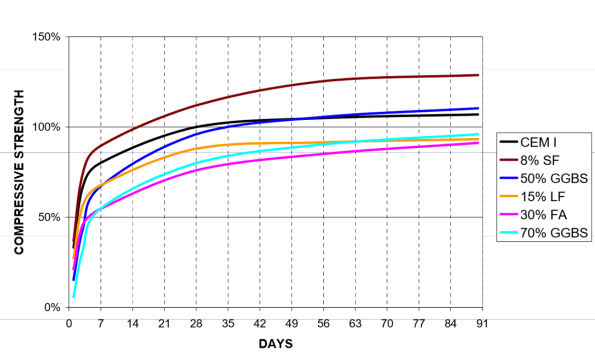

- Replace up to 50% of cement content of concrete with Ground Granulated Blast furnace Slag (GGBS): (the civils will know more about strength implications and codes for this but BS 8500 gives the guidance on tolerances).

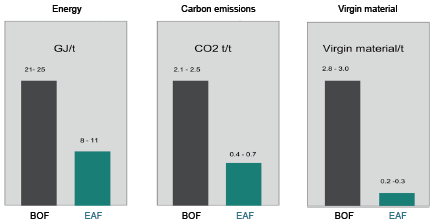

- Specify Electric Arc Furnace (EAF) steel (up to 100% recycled steel) over Blast Oxygen Furnace (BOF) steel (up to 30% recycled steel).

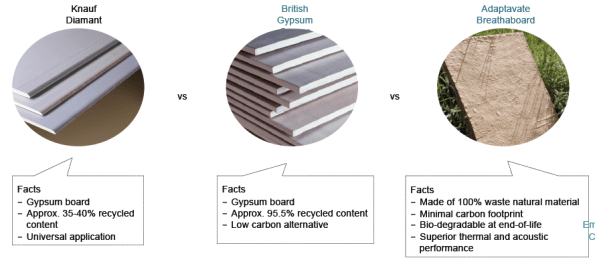

- Consider natural materials for internal building fabric. Caveat to this is that the ‘adaptavate Brethaboard’ below will require thicker plaster finish skim than the other two. Other alternatives products exist using natural clay which can absorb and release moisture into internal space, thereby passively regulating humidity.

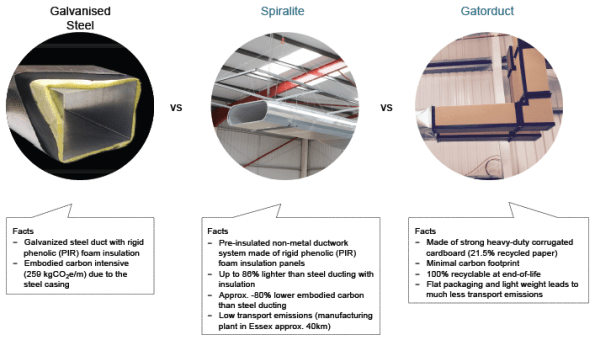

- Replace traditional steel ductwork with alternatives. To me, this might be the most difficult to get agreement from a client familiar with steel design going in and indeed steel ductwork is the generic requirement for all of Gatwick’s HVAC systems. However, in certain situations, such as relatively short lifespan / high turnover retail installations, the Gatorduct might be an better option.

I’d be interested if these types of products are commonplace on other sites indicating that perhaps Gatwick’s construction department remains too traditional / slow to catch up? Or maybe just meeting programme drives designers / contractors to stick to what they know?

Slides to go with Tom’s reply:

Defects in Melbourne Fitout

I am currently working in the “tenancy team” at Norman Disney and Young in Perth CBD. The tenancy team completes small scale building services consultancy fit out projects in a short period of time – usually a couple of weeks from start to finish.

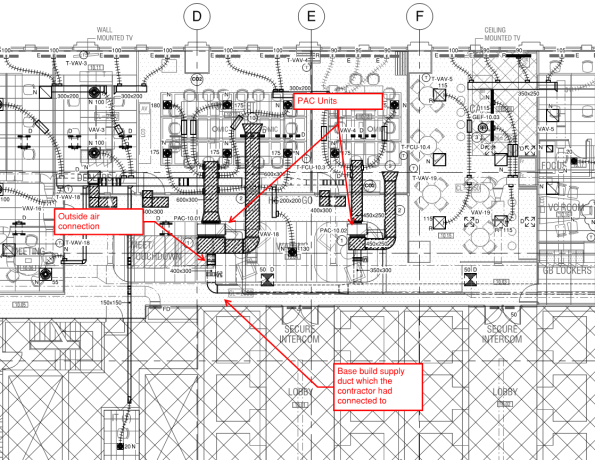

Amongst several other small projects, I have been given responsibility to consult on the mechanical construction phase of a HSBC tenancy in Collins Street, Melbourne. During the commissioning phase, a colleague of mine in Melbourne compiled a defect list, which happened to be extensive and include a number of concerning items. Given the tight timelines, by the time I received this document, users had moved in and started operating in a functional office space. One defect in particular was alarming – the mechanical contractor had connected outside air provision for two packaged air conditioning (PAC) units to the existing base-build supply ductwork. This presented a series of problems:

- Insufficient outside air provision to the two main meeting rooms.

- Imbalance of the existing base build system.

- Conditioned air being introduced to return air in the PAC mixing boxes.

To make matters worse, the client has unsurprisingly received complaints from the users – half complain about being too hot, while to rest are grumbling of being too cold. As the proverbial rolled down hill in my direction, I was asked as the mechanical design authority to rectify the situation. Both the builder and mechanical contractor were naturally eager to shift responsibility to the mechanical design, when in fact the system had been installed incorrectly. After an afternoon of rather animated phone calls and meetings, the mech contractor is now starring down the barrel at removing office users, taking ceilings down and installing the ductwork correctly. And rightly so! Understandably, both the builder and contractor were set on blaming the consultants design and I had the pleasure of going through the system design calculations with both parties. Luckily NDY’s design and quality assurance for this particular project was thorough and correct.

See Mark up attached.

I am somewhat surprised that the builder/ project management company allowed the user to move in before all of the defects had been addressed. Additionally, the original commissioning results are incorrect, invalid and wrong. To that end, I am pushing my project leader to request a re-test by the mech contractor – with a perhaps a young, enthusiastic, British engineer in attendance 😉

Update – Picture for you Fran.

xx

Mendeley Desktop…it’s free!

Whilst writing my thesis I have found Mendeley Desktop to be an excellent reference management system and the citation plug-in for Word is well worth downloading as well. I only wish I had listened to Mark Hill and downloaded it before starting TMR 1!

Check it out – https://www.mendeley.com/

British Airways Medical Facility

As my Phase 3 placement progresses I am getting used to the systematic way that the design office undertakes a building services project. This blogs aims to describe the process using a small task I am running with (it is related to aeroplanes – exciting).

The Project:

British Airways have a flight training facility at Heathrow centered around a hanger with a row of articulated flight simulators. The surrounding building contains the plant to operate the machines and a number of offices.

Flight Simulator Hall. I wasn’t allowed to have a go in one.

One office has fallen into disuse so BA has decided to convert it to a medical facility with the following spec:

- Waiting area with seating for six.

- Three conditioned treatment rooms.

- Tea point and unisex toilet.

- All spaces are to be cooled or heated as necessary, supplied with ventilation, hot and cold water and electrical power.

The area is currently used as a storeroom and janitors office – it is unheated and has a number of bits of old air conditioning plant running through it.

Medical facility – current state. Some homeless facilities manager has been squatting here for a few months, hence the PPE.

Design Process:

The M&E design process at Bryden Wood is almost identical regardless of the size of the project. However, a bit like the combat estimate the cycle is scaled to the time and resources available to the task …. smaller project = less money = less detailed design. With the very small scale of this task the entire plan has to be completed in about a week, giving it the feeling of a Phase 1 design project. Generalised steps to the design are included below:

Schematic of the existing plant room space. Note the Air Handling Unit at the bottom right that the new ventilation design aims to tap into.

Step 1 – Fix the Spec. Meet the client and hammer down exactly what they need and are willing to pay for, bearing in mind that these things are usually decided by different people with very different priorities. During this process I listened to the nurse’s passionate pleas for a tea bar with coffee grinder, zip tap and dishwasher. This has subsequently made it into the design as a sink.

Step 2 – Develop Strategy. This is arguably the stage requiring the most engineering judgement. Decide on what systems are needed to meet the client spec – how it will be heat, cool and ventilate the space. As an example, at this stage I decided to use a wall-mounted unit to provide cooling and piggy-back on a nearby air handling unit to provide ventilation. At last I can now sleep at night.

Step 3 – Calculate Room Loads. Work out the worst case cooling loads (people, lights, solar gain, and equipment on the warmest day) and heating loads (empty room on the coldest day). Add 15% extra capacity for future expansion, wear & tear, etc. Follow a similar process for hot water and ventilation rates. This is easy, bread and butter stuff following CIBSE guidance and rules of thumb.

Step 4 – Speak to Manufacturers. Talk to our favorite manufacturers (the ones who buy the best free lunches) and ask them to quote for the systems needed.

Step 5 – BIM Modelling. Model the selected systems in Revit (the chosen Bryden Wood BIM programme) and ensure there are no clashes with the existing sites systems. I usually outsource this step to an apprentice CAD draftsman who uses Revit like he is plugged into it Matrix-style.

New room ventilation plan. This sketch is handed to the Revit techie who turns it into a sexy model for the client to peer at.

Step 6 – Paperwork. Complete the diligence paperwork required to provide we have met the Principle Designer responsibilities and manipulate the Revit model to produce the final design drawings. Sit back and enjoy tea and medals.

Open Doors

Just been told about this. Might be an interesting visit if anyone wants to wander around a few construction sites. You could potentially argue that it’s CPD at a push or steal a good idea from one of these sites, apply it on your own, and look like a hero!

IStructE guidance

Writing AER 5 has prompted me to signpost some guidance for the Phase 1s as they move to their site attachments. It would also be useful for the next batch of phase 1s but I doubt they’ll see it unless one of the lecturers can pass it on.

Join the IStructE as a student member. I don’t think it was covered except for some structures ninjas attempt to charter with IStructE. Maybe I slept through that advice in Phase 1 (my fault) or maybe it wasn’t covered (it should be).

It’s free, you get access to their online library, learning resources, student groups and talks, essential knowledge series, “Brohn” online modules, “The Structural Engineer” (online only), you can join their working groups (good CPR evidence)…….and most importantly it’s actually a navigable website unlike the ICE one. I feel they support learning in the way that the ICE should be doing (clearly not a point i’ll be making at CPR).

Join here:

Specifically:

The essential knowledge series is really simple introductory reading.

The level 1 technical guidance notes would be useful pre-reading before the corresponding lectures on phase 1 and as a refresher when you come back to that topic on phase 2.

The level 2 technical guidance notes are a good starting point for any phase 2 or 3 design you need to do in that subject area and they all highlight recommended further reading, generally easily understood IStructE design guidance. These are still being written.

Level 3 notes looking at complex design issues will follow during 2018.

I plan on coming back to them as a handrail after i’ve finished the course as well.

ICE CPR Written Exercise

Last night I attended an ICE event on the Written Exercise (WE) portion of the CPR. It was not a technical seminar or anything of the sort. It was one reviewer, Ian Jenkinson, giving us his opinion and guidance on the CPR in general, but focussed on the WE.

Ian Jenkinson has been an assessor for over 30 years and at some point or another has sat reviews with over 25% of all current reviewers. So his opinion on the review carries a bit of weight and shows a good spread of the opinions of most reviewers.

After the talk I felt much more at ease with completing the WE and taking the CPR on a whole. One of his key points (in the slides) was that the CPR is not an interrogation or a discussion between two adults (reviewers) and a child (us), it is a discussion between three engineers.

The slides you might find helpful, but I will summise a few of his key points here:

- The questions will be picked based on what you say in your report – through this you can essentially set your own questions.

- The reviewer will check you have some knowledge on the subject during the review, if they believe the question is unfair or they have not understood your report, they can still change the questions before you sit the WE.

- When answering the question:

- Do an essay plan (If all else fails and you have cold sweats and palpatations – people have still passed the WE based on a good essay plan

- Tell a story – this is not a technical paper

- They are looking for a good first draft (not polished ICE Journal submissions)

- Use minimal direct quotes and reference them properly – plagiarism will fail you

- Better to use your own thoughts, reasons and communicate them succinctly

- Some examples he gave had typed essays in the region of 1000-1500 words

- Well laid out but no unnecessary formating, front pages etc

- Another key point he made was not to get wound up about the essay. You won’t fail CPR based on a shocking essay, if you fail CPR it is because of the interview session.

- Alternatively, if you have a shocking interview, the WE might turn it around for you (on one attribute…maybe).

- Less than 0.5% of people fail CPR with the WE stated as the reason.

The marking rubric consists of three pairs of characteristics of the WE:

- Knowledge and relevance

- Grammar and syntax

- Clarity and presentation

Questions asked:

- What if the questions you get you cannot answer – Speak to the invigilator and they will help as best they can – he implied that there is always a way to answer the questions they set.

- What attribute do most people fail on – Independant judgement and responsibility. Ian spoke about taking responsibility and saying “I” and what the outcomes and consequences were to your actions. Secondly he said commericial awareness lets people down, but having a base knowledge of the contracts your projects were under would get you 90% of the way there.

His last point, and a slide that isn’t included in the pack was that they are not looking for the ultimate polished engineer, but an engineer who has the potential and drive to become a good engineer.

I hope this helps and sets a few minds at ease about the CPR process as a whole. It would be interesting to hear some of the guys opinions who have been through CPR last year?

Thesis: Information Overload!!

I’m sure all but the most organised of you have experienced something similar, even if you’ve subsequently solved the riddles and moved on!? I was hoping to get some advice that might help me make better use of my time over the coming two months.

Having extended my TMR4 deadline, then had the audacity to take a weeks leave at the end of February, I’m now beginning to feel the thesis crocodile circling closer and closer to the canoe. I’m extremely conscious of upcoming deadlines, but having gone out and collected as much data as I can, I now think that I’ve got too much and I’m struggling to refine it into useful material of the right academic level.

My thesis is on the structure of the Royal Engineers, and how we might consider re-structuring ourselves in order to better deliver effect on Operations. My basic premise is that the current historic structure (Platoons, Companies, Battalions, Regiments etc.) was/is fine for fighting wars, but pretty useless for undertaking construction tasks, not only does it seem to be an ineffective way of managing skilled tradesmen, but it also appears to leave managerial skill gaps within the command structure.

My main issue is that having obtained no less than 20 PXR/POR/PERs from the TICRE (luckily there was plenty of stuff they didn’t have or I’d have ended up with even more), together with the latest Project ANEMOI Lessons Learned document, I’m currently sitting on hundreds, probably thousands of pages of text (of varying quality and command level) that I’m attempting to evaluate in order to find reoccurring themes and patterns. I was keen to avoid any kind of selection bias by simply choosing the reports I liked the best, but in doing so I’m finding it almost impossible to pick out the most useful (and relevant) lessons learned. I could write a whole literature review on just three or four of the reports on their own, so having complied a spreadsheet of lessons learned from all 20, I’m struggling to condense them into useful (academically sound) results. So far, all I seem to have done is hand select obvious anecdotes with little further analysis. It’s like finding passages in the Bible or Koran; search long or hard enough and you’ll find something that backs up your opinion. The rest can just be discarded, even if there are a similar number of anecdotes contradicting the first. It feels like I’ve almost gone the other way and that having too much information is creating its own bias by allowing me to pick and choose what I want rather than what is actually relevant or meaningful.

Did anyone else have similar issues with regards to information overload, and if so what strategies did you employ in order to focus your efforts and obtain useful, valuable data from the sea of literature available?

PS: Please no “I’ve almost finished my thesis you should have started earlier” comments!