Sustainability through Design

Conscious that CPR is just around the corner and Sustainability still looks to me like a vague, tree hugging engineering attribute, I have volunteered to join the Robert Bird sustainability working group. Made up of engineers from varying disciplines (Geo, Temp Works, Civil’s and Structures) and experience depth/seniority, our objective is to develop a sustainability approach within RBG and provide focused support to ongoing projects.

In today’s meeting a senior project director asked us to look into a very specific client request to try understand the risks and opportunities from a sustainability perspective. In broad terms, the local planning department and client have mandated that 25% of all aggregate used in his project must be reclaimed. Though we have a 40 storey concrete residential structure in which we could potentially hide this high percentage of reclaimed aggregate, unfortunately the structural engineers have told us they do not want to use it in any columns or beams because they are concerned about its performance.

The interesting thing about this mandated condition is that we have no context to its origin or underlying intent. By that I mean we have no idea what the planning department aims to achieve by it or if it was just a random number plucked out the air by a Planning Department work experience undergrad ? Most of the team assumed it’s to reduce the carbon cost of the project. Someone thought it is intended to reduce the number of vehicles transported to site and one engineer suggested it is simply to save cost. At this point we don’t know.

Has anyone else encountered this requirement before and have any views on its impact?

We are now researching the following basic angles to increase our understanding of the options open to us.

- What is the key incentive for this planning constraint?

- If it’s to reduce the Carbon cost and we can’t get 25% reclaimed agg into the design, can we offset this shortfall with other C02 saving methods: ie use of GGBS or other cement replacement products?

- What are the structural issues with using Reclaimed Aggregate and how does it affect performance?

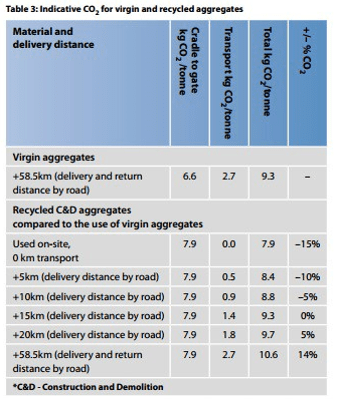

- At what point does using reclaimed aggregate actually add to the Carbon cost and are there suitable suppliers within range of task site? The following image shows that as the distance of transport to site exceeds 15km, the carbon saving is eradicated.

Anyone got any thoughts or experience of this stuff? In the meantime I’ll be chained to a tree at an anti fracking protest whilst waiting for answers.

Cheers

TD

Tom, using (or rather reusing) reclaimed aggregate is a good way of reducing the embodied carbon on a project. However this depends on how far the aggregate has to travel in order to get to site (as you have mentioned).

Laing O’Rourke are big fans of using precast concrete. Using precast concrete sections (especially for columns and walls) allows the amount of waste material used to be reduced significantly, finer quality control and reduced installation time (therefore less vehicles required for concrete deliveries, steel deliveries, etc) when compared to casting in-situ.

I don’t know how reclaimed aggregate will affect the structural properties of concrete so keep us posted!

Fred, unfortunately we are not using Pre-Cast but I agree with your point. We are now considering likely applications for the concrete after the building is dismantled in some 45 odd years. Ive never worked with Pre Cast so is it easier to take down when dismantling the structure? Ie If you lift and drop pre cast panels into place during the build how easy is it to lift and remove the same elements? Would being able to cart the panels away on a truck would save on any breaking out costs?

Tom,

Good to see a sustainability drive from the design side rather than just on site. in my experience the main aim was to reduce embodied carbon and CO2 emissions. Therefore any measures to remove spoil by barge or to turn off generators etc was all fed into the two figured above. The target if I remember was a 25% reduction in carbon emissions and embodied carbon. The unfortunate thing on the NLE site was that it seemed like it was down to the environmental engineer to record and therefore it became her responsibility.

With regards to your recycling of aggregate. It sounds like your issue is not that the reclaimed agg will not reach the performance criteria. But that it is unquantified. Surely some grading and removal of fines will make it exactly the same as any other aggregate source. And if the performance is unknown, some sample testing should be fine to establish whether it is feasible or not?

As to the main Q : Yep , I don’t know the detail but you can recycled agg for replacement to designed concrete up to about 20% and for up to C50 grade.

At 40 storeys you might be OK with C50 but might not.

As far as I know it is fairly common …ask WRAP… they know this stuff.

On the wider point it must all be about full life CO2/energy load

SInce the structural cost of a building is about 10% of first build cost and since the

first build cost is about 30% of the full life cost ( the 70% being largely the energy used as a building is used) and since the re-use of agg is about a micro small amount of embodied energy in the aggregate content…….of the structural element of the build cost……. do you see where I am going with this?

Hence we have standard metrics to determine how ‘sustainable ‘ a build is

BREEAM uses 9 measured metrics one of which is ‘materials’

As a structural team you could ‘save’ 00’s if not 000′ if no 0.000’s more CO2 by ensuring that the H&V services are efficient and maintainable – try to ensure ducts can be circular and accessible for maintenance

IN other words single point targets are f*****g pointless arse-gazing nonsense…..

I’m fairly sceptical about measures like BREEAM but at least a high BREAAM rating might actually achieve something……and since the building owner sees tangible bottom line for a high -sustainable asset ….there might be more visceral drive behind trying to reach a BREEAM target

Tom,

Not specifically with regards to aggregate, but I have come across a number of incidents of the tail wagging the dog with regards to sustainable design. Over here we use LEED which though different, is broadly comparable to BREEAM in that a certain number of credits need to be obtained in order to receive a bronze, silver, gold or platinum rating. Though I’ve only worked on limited projects, the trend seems to be to gather as many credits as possible by manipulating the process and criteria without actually considering sustainable design an by doing as little work as possible. For example a very small ‘green’ roof is set to be installed; when I ran the calculations I came to the conclusion that the ‘green’ roof would have negligible effect on the thermal properties of the building, and that no one had considered the long-term management of the space. In effect the maintenance burden of the green roof would actually make the building less sustainable, but who cares it’s a credit!

Also, because of vegetation removal during the site clearance phase, the project team re-planted a number of trees to off-set this loss. They got the LEED credits ticked off, and then the river near-by flooded and the majority of the trees were killed. It turns out there was a reason why trees weren’t growing there in the first place! Although I left the project at Christmas I believe the project is set to lose a number of transportation credits because a planned bus-stop has been scrapped and isn’t due to be replaced. The LEED team will no doubt be trying to work out where they can scramble together some more credits in he final stages of the project, hardly what the LEED scheme was intended for! I’m sure there are some examples of good sustainable design out here, unfortunately my experience has been more one of box-ticking than an integrated planned process!

Thanks for the responses, I am trying to encourage the sustainability team to influence the strategy to look at CO2 saving with a wider, full life cycle view. Most accept its just a number plucked out of some misunderstood guide so early next week I am off to the Green Buildings Council (Sustainability Gurus) to discuss this in detail. In the meantime the Geo team have been bought in to see if we can hide/bury a lot of the reclaimed Agg quantity in the huge load bearing piles, like the 1950s Mafia.

Click to access BRE-Digest-4331.pdf

Tom, a mildly useful article on recycled aggregate