Thoughts on over excavation of a contiguous pile retaining wall…

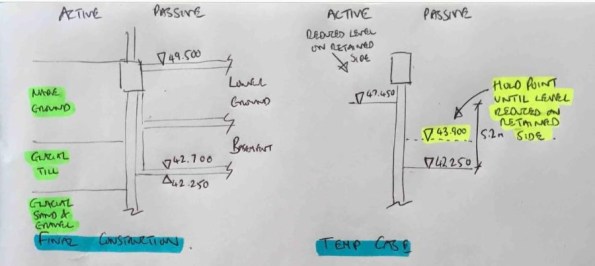

I’m currently looking at the implications of over excavation on the basement (passive) side of a contiguous piled retaining wall. Whilst onsite I became aware that the sub-contractor responsible for the basement reduced dig had moved beyond a hold point before another sub contractor had completed the temporary reduced level on the retained (active) side. The reasons for this are numerous but boil down to poor communication and management of the required design construction sequence. Figure 1 below is a sketch of the wall cross section during final construction and temporary cantilever states in accordance with the design checks conducted.

Figure 1 – Final construction and temporary construction stages

In order to understand the impact of this error I wanted to analyse the impact of the worst case (figure 2) where the full passive excavation had been completed and no excavation had occurred on the active side. Note that fortunately work was stopped on site prior to this case occurring!

Figure 2 – Worst case if construction sequence followed incorrectly

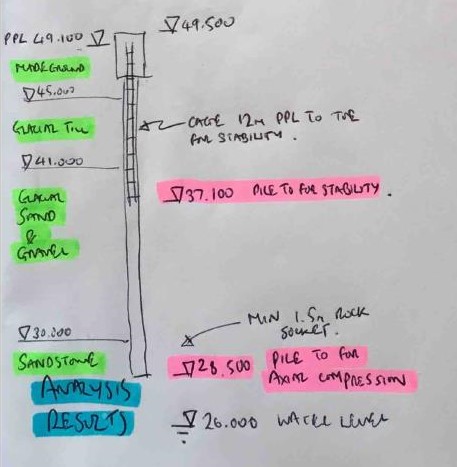

The initial WALLUP retaining wall analysis (step 1) gave a minimum pile length for stability of 12m from pile platform level (PPL) to the toe at 39.1mOD. Re-analysis for the worst case shown above caused an increase in the max BM, shear and displacement of the wall in SLS conditions and a failure in ULS conditions due to passive failure. This would be a simple conclusion if the wall had been constructed to the 12m length from the original retaining wall design. However, the contiguous wall is also required to support an axial load for the planned structure above. The initial analysis of axial capacity (step 2) lead to a minimum pile depth for axial compression of 28.5mOD and a pile length of 20.6m from PPL. This design was based on resistance provided in skin friction below formation level and a minimum rock socket of 1.5m. Note however that the initial structural reinforcement design (step 3) only extends to the depth calculated for stability (in step 1) and was based on the maximum moments and shear from this calculation. The image below summarises the initial pile design results.

Figure 3 – Initial design analysis results

So, drawing conclusions now on the effect of the over excavation shown in figure 2 becomes slightly more difficult. My initial thoughts are:

1. The passive failure issue is now removed due to the increase in pile depth.

2. There is still an increase in BM and shear force that would mean the structural reinforcement would be under designed and could lead to an STR failure.

3. The structural reinforcement should extend down to the new pile toe depth for stability.

4. There would be an increase in deflection of the wall which could lead to other issues including eccentric loading in the final permanent state.

I’d welcome any comments or thoughts on the above logic or any conclusions I may have missed.

James, nice issue to discuss.

Was there any allowance for an overdig in the design? Out of interest are all like cages the same length on the site. If there were other areas of deeper excavation there might have been a standard cage length used which might again mean they are longer than needed for the area you have the issue. Can you explain point 3 – why to pile toe?

What measures are now in place to stop this occurring again? Have you got any monitoring on site or existing structures behind the wall you are worried about?

Damo,

Thanks for your thoughts, to (try to) answer your questions:

1. There was a 0.5m overdig allowance in the ULS case. However, this only protects against the risk of minimal overdig linked to level and plant accuracy, not against proceeding past a hold point.

2. The contiguous wall was split in to 5 different design areas based on ground conditions and required excavations. The design case above is for area 3 and covers approximately 50 piles.

3. In the original design the cage reinforcement was based on a pile toe depth of 31.1mOD so 12m from PPL. The worst case BM, and shear from the ULS/SLS analysis in WALLUP was then used for the structural steel design. Re-analysis showed a passive failure for this 12m pile. Therefore a longer pile is needed for stability in the cantilever case and a new pile toe depth for stability would need to be calculated. Let’s say this said the pile needed to be 14m – structural reinforcement would need to be recalculated for this length. So in summary, the reinforcement would likely need to be increased in area and extended further.

4. The dig is now complete in all areas next to the capping beam. All parties involved have been re-briefed on the design and possible implications. An ITP has been updated/created with all the mandated hold points requiring PC review.

5. The capping beam is being monitored by survey and trigger value deflections have not yet been met. No significant existing structures close to the area. The trigger values are very low (~20-30mm) and would not cause significant settlement behind the wall. My analysis was more hypothetical along the lines of what is the worst that could happen if we hadn’t stopped the dig. Worst case there is a road ~10m behind the wall if total failure did occur.

Hopefully I’ve articulated my reasoning on point 3 a little better now although.

Looking at the job and the Qs

1 I agree- a GEO ULS was not likely to control this early dredge stage ( albeit 30kN/m2 surcharge over the design). I suspect a temporary surcharge of 20 or so was built in. So omitting to reduce the active side surcharge was not quite the whoops! it could have been. I would have thought the issue will have been deformation- it looks like there is a monitoring system in . Looking at the ground conditions; the material generating active pressure is 2 m fill and 4m of Till – So largely ( hopefully) fine grained and therefore the full load develops with time.

2 The cage extent is betraying where the designer thought the flexural problems would be. This might well be STR at full dredge if the thing is bottom up ( which I presume it is)

3 Not quite clear on the comment. If the pile is not acting as a flexural moment it doesn’t need a cage. There is a tendency to place full cages all over the place. Often not needed and often ( particularly for long piles – cause difficulty in sinking the cage

4 IF the wall were un-propped in the permanent state then a starting eccentricity would matter lots. As it is it is multiply-propped so no worry there

James, loved your blog. My comments are : are you monitoring the wall? What are the deflections? I bet they don’t match WALLAP! Has it moved more or less? What does that tell you? I assume you are in fine grained material? What freedom constraints can that give you.