Archive

BP – Glen Lyon flow transmitters

Just thought I’d provide a quick update on a piece of work I’ve been doing recently on the brand new Glen Lyon floating (is a ship), production (includes an oil rig), storage (capacity 850,000 barrels) and offloading (requires tanker to come alongside), or FPSO for short.

Glen Lyon FPSO

I have been drafted into the Operations engineering team to project manage an issue which happened last week. This issue relates to the gas turbines (GT), of which there are 4, and the Waste Heat Recovery Unit (WHRU), one per GT. A brief synopsis is as follows:

At approximately 1500 on Friday 27th of October, whilst producing circa 100 mboed (1000 barrels of oil equivalent) and during stable operation, a shutdown signal was sent from GT2’s WHRU flow transmitter, initiating a GT2 shutdown. This resulted in a number of cascade trips that eventually caused a production shutdown due to complete loss of FPSO main power (a separate issue currently under investigation).

On initial investigation it has become apparent that GT1, GT2 and GT3s WHRU flow transmitters have all degraded and began to physically leak externally at approximately 50-60 drips per minute. The subsequent failures discovered over the W/E of 28th – 29th October have left Glen Lyon with only 1oo4 GTs availability and unable to ramp up production as a result of the failure.

This is clearly super bad for BP’s flagship asset, which is one of its highest produces. This clearly attracted a lot of attentions from VPs etc. I became involved at the request of the asset for support to project manage the recovery of the WHRUs and the switch over to main power. The immediate issue was the recovery of at least 2oo4 GTs which are required to provide power to the main thrusters to provide stability during an offload to a fuel tanker. By delaying the offload there is a deferral in potential income for the oil that is not being exported. The issue was compounded when a potential procedural issue caused the bursting disks to rupture on the cooling medium system on the only working GT.

Before I describe the options available I’ll explain the flow transmitter layout. Each WHRU has 1 flow transmitter which consists of 16 off transducers which are circumferentially mounted on a 10”pipe (providing 16 potential leak paths). See photo for what these physically look like.

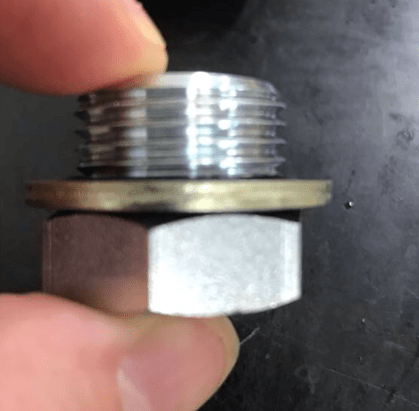

The immediate short term fix was to drain the system, remove the transducers and plug with a standard bolt (short plug) and dowty washer arrangement (see photo). This was the quickest, but the most temporary option available. This was completed for GT3 on 2nd November.

Short plug and dowty washer

The second, and preferred option, is to machine new housings from solid 316L stainless steel, using the dimensions from the original transducer manufacturer. These were expedited for GT2 but failed to fit due to a ‘tolerance’ issue (they were within tolerance so we think they might have messed them up!!). We then had to revert back to using the short plug option which was completed 4th November. This allowed us to run up 2 off GTs on diesel and offload c.200000 barrels to the tanker. The problem with using the short plugs is that they notionally have 2 week expiration on their suitability, which will then need to be changed out for another option. At the present time the machined housings have been re-machined and sent offshore on air freight. The plan is to plug GT1 and GT4 with these.

As a further contingency, 4 off pipe spools have been manufactured which will replace the flow meters and remove the risk of any leak paths. These spools had a lead time of 10 days but will require to be shipped by boat. The current weather is causing issues with offloading as it is a boat to boat lift. These are likely to be offshore next week.

Pipe spool – 600m length c.125kg – must be shipped by boat

The initial headlines have died down somewhat since the main power is back on, the offload was successful and the plant can begin to ramp up production. It has been an interesting experience to be involved in crisis (project) management. The way forward now is to conduct a root cause failure analysis on the transducers to provide a long term solution. Depending on the time required for this, the immediate plugging solution will require change-out for an intermediate solution, likely the pipe spools. I’m likely to be involved in this for the next few weeks at least, with a business call made on my other projects to put them on hold.