Saving “Piles” of cash

While not something I am directly involved with on my site, I came across this method being used in the dressing of pile cages in a bid to save both money and time further down the line and thought it was worthy of a quick post.

The works here on the North Portal includes the construction of a “waterproof box” inside which the two Tunnel Boring Machines (TBMs) will be built and launched, followed by further construction to complete the portal structure to its final glory as depicted in Fig 1.

Fig 1. Artist Impression of the North Portal

In broad outline we are installing a Continuous Flight Auger (CFA)/bored secant pile horseshoe and then excavating to ~20m before pouring a base-slab to key in with the pile wall to provide that box which will hopefully keep the water out. (The open end of the horse shoe is to be closed off by means of a grout curtain, or using cutter soil mixing (CSM))

In order to facilitate that connection between base slab and wall, deal with uplift and ensure a waterproof structure, couplers are being installed in the secant pile cages to allow the tie in of rebar once we get to depth, see Fig 2.

Fig 2. Pile wall/base slab tie in (Auggy, age 5)

The 40mm bar and coupler can be seen below as well as the setting within the reinforcement cages;

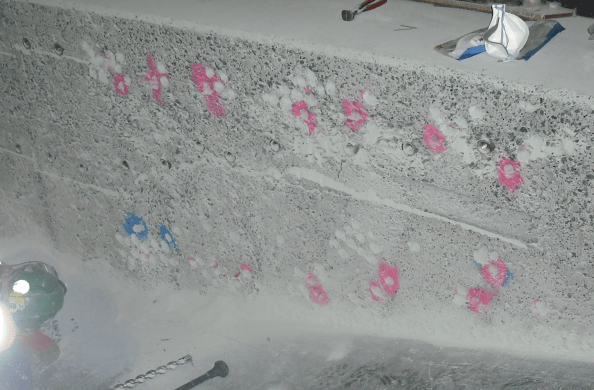

This might be how the cage is traditionally dressed before being set in the pile. The fun then begins once the excavation has reached depth and the couplers need to be located prior to establishing the base slab. Reminiscent of a game of pin the tail on the donkey, locating the couplers can be quite tricky, see Fig 5, and the hydro-demolition technique used quite expensive.

Fig 5. Find the Coupler

In order to avoid this the piling team have decided to used polystyrene and plywood to block out the area of the pile around the coupler. Adding a little bit of extra faff to the dressing of the cages will hopefully pay dividends when we get to depth in the excavation.

Fig. 6 Dressed cage

I will let you know how it goes. Hopefully interesting and maybe useful for some, though I’m sure it is not the first time it has been done.

* On a side note the piles going in at the headwall of the portal are using Glass Reinforced Plastic (GRP) instead of steel reinforcement. This is to avoid unnecessary wear on the TBM cutting heads before they even start! (I hadn’t heard of that being done before)

Boxing out is a normal practice in situations such as this but I have to say that it has always been problematic/challenging in piling because the polystyrene panels you have will be prone to being dislodged if operatives don’t handle them with care. Making them more robust always seems smiley to act as a greater challenge to be overcome, red rag to a bull etc. The issue with couplers rather than just socketing out for exposing the bars to enable lapping is that the cages frequently end up either slightly out of position in elevation or manage to rotate on plan leaving couplers out of place/alignment. In all applications with breaking out to reveal couplers there is a considerable risk of damage to the coupler. I will be intrigued to know how these challenges are overcome and how successful you can make it.

Auggie

Good blog.

Is the raft thicker at the edges? If it was thicker for say the width of a bar lap plus a bit, with the coupler set out to be in the middle of the thicker strip. This would allow for the couplers being out of toleranceTo an extent.

What are the D shackles for in the picture?

Brad

Had a look at the design Brad and chatted with one of the other engineers. It doesn’t appear that anything has been incorporated into the design for out of position couplers, which could be interesting when we get to depth. I’m not sure site engineer checks where all that swept up on the first couple of piles either so….

The soft panel is just more secant piles wall with Glass Reinforced Plastic (GRP) instead of steel rebar.

Oh and the D-Shackles are being used to suspend the cages on horizontal lengths of re-bar to set the height or the coupler

How is the soft panel being made to allow the TBMs to dig out of the box?

Auggie, who is holding the risk if this doesn’t work and the polystyrene ends up creating a void in the wrong place? I ask, as I have had a similar conversation with our piling contractor recently over similar issues locating waler bracket connections and they have initially refused the polystyrene idea as it has caused them contractual issues in the past.

We are holding the risk as we think due to the method of fixing the “block out” there is very little risk it will come off. I think normally people have done it without protecting the polystyrene with plywood like we have, hence chunks have come off. Where you planning to protect the polystyrene in any way? We have our guys fixing it to the cage also.

Auggy,

This is a very good blog in that it raises several nuggets that are very pertinent to the understanding and approach of a CEng. Have a think about Glynn’s question. Who is positioning the cage within the pile? If the box-out ends up in the wrong place what action will be required, will it nullify the piling contractor’s warranty, who will pay for the remedial works and how will they be warranties. How will the issues relating to cage position versus risk ownership of the concept be resolved. I think the answer to most of this is, if it involves money, time or reputation it will be a dispute and contracts will be looked at. Contracts address risk. How is this one being allocated?