Home

> Uncategorized > They keep slipping up

They keep slipping up

A really juicy one here on concrete for the E&M’ers to get their teeth stuck into.

Here is something to watch out for if anyone is involved in slipforming.

-

- The four shear cores in my area at Battersea are being built using slipforms. The main benefit of this method is that it can be constructed very quickly (if carried out by a competent contractor with adequate round-the-clock quality assurance).

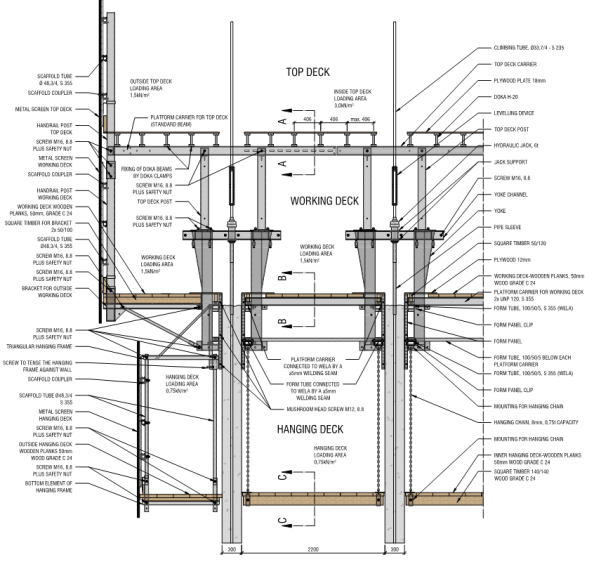

- Quick recap on Slipform: Shuttering (the formwork) is attached to yolks, which are held up by climbing tube. The slipform rig is held up entirely by the climbing tubes which run to the base of the slipformed wall, and the jacks are almost continuously lifting the slipform rig. The concrete that is exposed below the shuttering only needs to support it’s own weight, which is continuously checked as the slipform is lifted.

- The axial force produced by the jacks must overcome the friction between the shuttering and the concrete to allow the shuttering to move up. However, if the shear force due to friction between concrete and the shuttering overcomes the shear strength of concrete then the concrete can fail at the surface, resulting in poor finish. If the concrete has cured and the shear force overcomes the tensile capacity of the concrete then whole sections of wall can be dragged upwards. This happened on one of the cores in Battersea, resulting in large tear-outs and long delays.

- Sub-contractor’s reasons: The high strength C75/85 concrete that was used in this particular section of wall was going off too quickly, resulting in it adhering to the shuttering. A possible but flaky argument trying to transfer the blame to the concrete mixers.

- Weapon fires, weapon fires, weapon stops… The concrete was repaired using traditional formwork on the hanging deck, and after 8 days of repairs slipforming continued as normal… for a few days until the same thing happened again in an area where the normal C50/60 concrete was being used.

- What was the reason for failure? Slipforming is supposed to be a continuous process, so that the concrete is given time to harden in order to support it’s own weight, but not given too much time because it can adhere to the shuttering. Also, this means that there will not be weak ‘construction’ joints with the concrete below which will give the concrete poor tensile strength.

- First incident (photos below): There had been a long pause in order to fix some large steel embedment plates before the concrete was poured. The concrete was poured on the night shift, where as it later emerged, the subcontractor had no QA managers working and an inexperienced concrete foreman/supervisor. It is possible that the high strength concrete was going off quicker, but this should have been anticipated and either arranged to be poured quicker or designed with admixtures to slow the curing process. An operative on site also let slip that the concrete looked as if it had gone off when it was poured.

- Second incident: (photo below) After the first incident, the exposed shuttering was cleaned, however the shuttering overlaps the concrete at the bottom by about 0.4 m to allow a good seal when pouring concrete. It is likely that in this area there is a film of concrete that has stuck to the shuttering, which makes it much easier for fresh concrete to bind to the shuttering. The failure occurred after a very hot day, which is likely to have compounded the problem due to increased speed of curing.

- After some investigation it seems as if the most likely problem is that the sub-contractor has not been managing their logistics well, allowing concrete to stand on site, or having large quantities turn up at once causing queuing. It seems as if there were two failings here; in logistics managemnt and in Quality Assurance. A real Sliphopopotamus.

Categories: Uncategorized

Nice. First photos look more like honey combing and not a tear. This hypothesis would be supported by the concrete partially cured on pouring and poor compaction anecdote. Second one looks more serious because there’s a lot of concrete not there and significant displacement of reinforcement (now fixed in position!). I’d suspect unfilled shuttering dragged upwards formed a void and then there was adhesion at the upper end leading to a void and tear; but that’s a necky assumption, like a giraffe but more easily spotted.

How much of a challenge is it to strip off the shuttering and clean it? I’d have thought it would be nigh on impossible. Is the slip form genuinely continuously jacked or is it slipped in stages?

What I didn’t explain is that in the first instance is that the tears were almost across the entire cross section and went all the way through the wall in several places. In the second instance they were a bit more localised, but much larger.

You’re right that it would be a big hastle to remove the shuttering, and would take a fair while.

The jacking isn’t continuous, but in an ideal world it would be. We want to try to maintain a layer of green concrete at the top as much as possible and have concrete that can support itself coming out of the bottom. The reason for it not being continuous is a practical one in terms of having space to fix rebar and box-outs etc higher up and also a logisitc issue as its not always possible to synchronise concrete arriving with there being sufficient space in the shutters to pour the next load. Also, if the slip is constantly moving, the operatives tend to get rebar, pokers and various tools stuck, which although amusing is probably not a good thing. The slipform is normally jacked in 50mm increments about 8 times an hour, then giving an hour or so to get the next load of concrete in (though this can vary depending on how quickly the concrete goes off).

As it happens, it seems like they are now back on track as they have has a few days slipping withoud any incidents. This has coincided with the return of their more experienced supervisor and us monitoring their concrete logistics more closely.

Stonkingly good photos Ed

No idea what the cause of the horizontal tears are; I know that it is likely to be in the undergrowth of what is called consistence. Part of this not really discussed much is cohesion; the concrete in the green state must ‘stick together’. The concrete is being dragged apart by the moving form

I don’t think release fluid is applied to the form- certainly can’t be in the trailing edge

Someone told that the mixes used tend to use a slightly altered grading – with more fines than unusual to prevent shear on the form.

I guess the concrete passing out of the form has to be off enough t support itself but fluid enough to permit the slip form to pass – sounds a tricky business

I know that if you have to twat about with box outs you can get trouble form the additional time involved

Yeah time is always an issue on slipform. Having to stop to clean shutters is less than ideal because it takes so much time and labour, but this could potentially be going on whilst repairs are happening. granted, it’s a lot of work though.

An easier solution would certainly be to use release agents, I haven’t come across these being used on slipform and it could be something to do with the pain of having to continuously apply it… Certainly better than getting tear outs though! Something I’ll look in to.

Interesting about the use of more fines, I will look into their mix.