Loads of Temporary Steel

Introduction:

This seems like a relatively unique engineering feat so thought worth a quick blog to share how I think it works and highlight an issue which will soon need addressing.

The original Shell House structure is being renovated. The clock tower and three sides of the facade stay, everything else goes. Also, an additional 4 storeys are excavated prior to building back up.

Image 1. Original Shell house structure

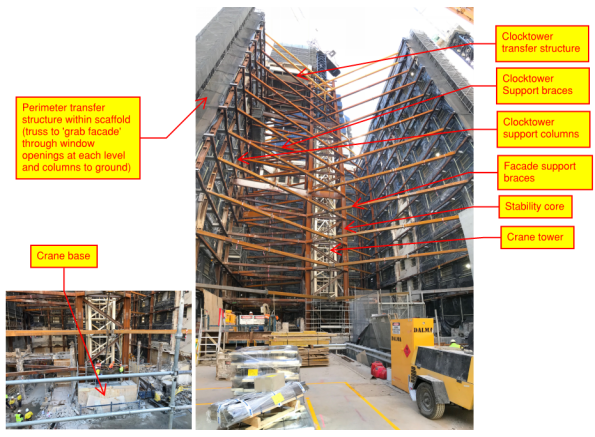

Retention works prior to demolition:

- Plunge columns

- Crane base

- Stability core

- Perimeter transfer structure

- Clocktower transfer and support elements

Retention works during Demolition:

- Façade support braces inserted as demolition progresses

Image 2. Facade retention system as at 24 Aug 18

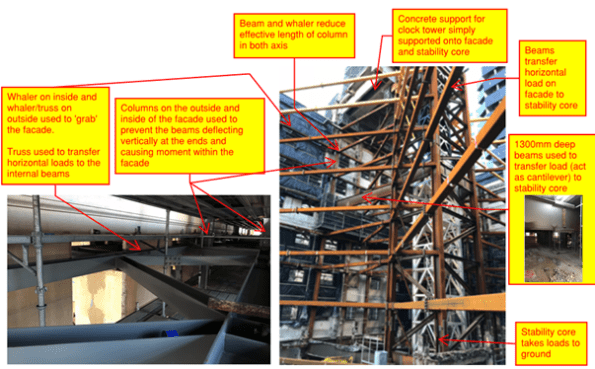

How I think it works:

Image 3. How I think it works

Retention works during excavation (soon to commence):

Image 4. Excavation procedure

Issue:

Plunge columns are up to 40mm out of plumb – what are the risks, how can they be mitigated?

I hope to answer these questions in my next TMR so any comments very welcome

Interesting post .

You sometimes wonder whether a lump of heritage of questionable aesthetic value might not be more easily;y handled by scanning an recreation

Anyway

So the moment at the base is through a set of piles; some in tension and some in compression. The columns have been plunges into these.

There’s no dimensions but the lever arm between the columns/piles looks quite low?

Hi John. My pictures doesn’t show the outer columns so maybe less moment in the columns than my photos allude to – the columns on the inside and outside of the facade act as outriggers for vertical load. Also fixed connections to these ‘outrigger’ so will distribute some of the moment from lateral and give bigger lever arm. Sandstone ground profile so not much lateral pressure from earth either.

Looks like really interesting temp works. Will you see it through to completion?

Who is responsible for it – PC or specialist subby?

Are there any significant ‘hold points’ during the sequence and who checks checks what?

The award winning Mr Murrow, nice of you to stop by.

Will see it through in terms of excavation but not the new construction/facade retention removal.

Everything is contracted out. Multiplex just coordinate. But they give me time to sit down with design consultants and I manage the subbys doing the works so still get to see the whole hog. Belmore are the structural steel specialists used.

They use Inspection Test Plans to ensure all works is completed and signed off at each stage before another level of demolition/excavation begins. Also got tilt monitors which give readings for how the facade is displacing, sends us an alert message if goes over the criteria set (goes off all the time as they are rushing demo so not isolation cuts and vibration gives them barmy readings during demo)