Top cover

I was walking to my demolition site last week and noticed a peculiar pattern on a concrete slab which had been poured as part of the new retail area.

It seemed unintentional so I asked a surveyor who was there when it was poured (as it was before my time) and he told me what happened. I thought it was interesting so I thought I would share it.

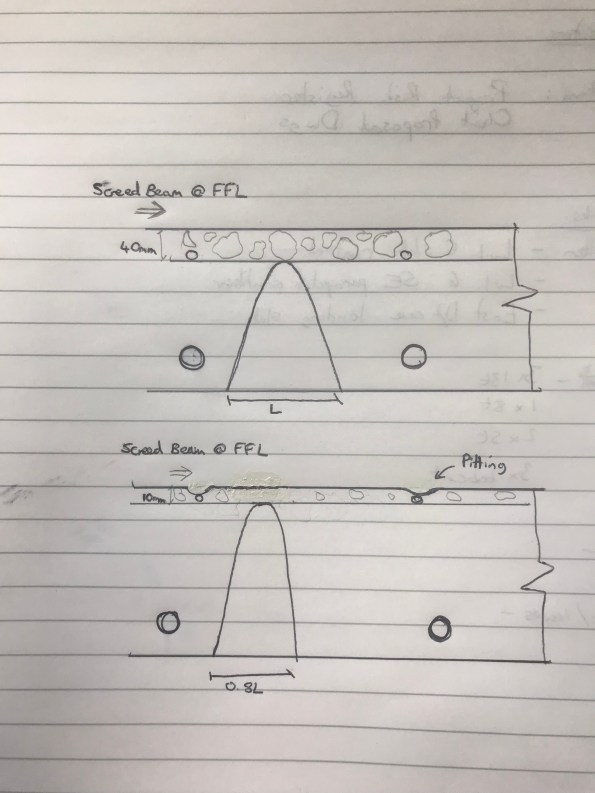

The slab is constructed with top and bottom reinforcement. The mesh at the top of the slab is held in suspension by small “chairs”. The problem arose from the chairs being the wrong size and therefore pushing the top mesh higher than it should have been. As the FFL was set the mesh ate into the top cover which was only 10mm where it should have been 40mm.

When the screed beam finished the aggregate in the concrete was pushed off the mesh as it was too big to sit between the FFL and the mesh. This meant that in the exact local of the mesh, there is no aggregate and a weaker cement mixture left. This has led to local settling of the slab in the exact footprint of the mesh.

It seems that this could have been rectified by a pre pour check and if it was identified the mesh was too high then the legs could have been spread out to lower the top, the legs clipped or smaller chairs ordered.

For whatever reason this didn’t happen. The fact this has been left might mean that the floor finish might cover these sins but it will not help with the durability of this slab.

Hi Ash

Not unusual to see this ‘quilting’ effect.

Have a look at;

http://www.concrete.org.uk/fingertips-nuggets.asp?cmd=display&id=645

Click to access reinforcement-ripple.pdf

It suggests that there is no detrimental structural effect. Important to understand the specification. Check out the guidance notes in NSCS;

Finishes 8.6.2 (p.99)

Flatness 10.9.1 (p.109)

Hi Ash

Not unusual to see this ‘quilting’ effect.

Have a look at;

Click to access reinforcement-ripple.pdf

It suggests that there is no detrimental structural effect. Important to understand the specification. Check out the guidance notes in NSCS;

Finishes 8.6.2 (p.99)

Flatness 10.9.1 (p.109)

Where the finish was an issue on my Ph2, we played safe and power-floated the lot. That worked!

Joe- thanks for that. Echoing my thoughts but just put much better. I think given it’s use as a commercial floor it will not need power floating and they will just stick some Lino over it. Interesting to read that it has no durability issues.

Power floating is part of the finishing process for a concrete slab. It is completed approximately 3 hours after the pour in order to provide a reasonably compact, level and uniform surface. The final effect has swirl marks from the power float and a texture like sandpaper. You can power trowel if a smoother finish is required. Note this does not remove the requirement for proper compaction and curing and is not a retrospective action. I think you are contemplating remedial works in the form of skim coats or screed (probably not required).

Pour lines and shadow marks are very common in concrete. They are not necessarily all bad but are generally not good. The explanation given to you is not a bad layman’s justification. The removal of a proportion of the coarse aggregate from the matrix is a significant factor in generating these marks. This then causes the resulting paste to cures differently to the rest of the mix and results in different shrinkage (not settlement). It also causes difference in colour, which serves to accentuate the effect.

It is interesting that there is a belief that the steel was incorrectly fixed. This would be surprising because stools would have been ordered to the correct size and steel would have been checked by the fixers own QA system and as a pre pour check. If it was out of tolerance it would have been corrected so a surveyor cannot have known it was out of tolerance and must be making this assumption/assertion after the event! More likely is that the concrete has been over vibrated a little and the pokers have been left lying in contact with the top mesh. This causes the mesh to vibrate and gives rise to localised variation in the paste composition (with some possibility of segregation), which then gives rise to differential curing, colour variation and potential differential shrinkage. It suggests poor workmanship on the concreters part and is a contributor to the need to have such large material factors on concrete.