Displacement Piling Precast Piles

G’Day from Melbourne!

As there have been significant delays to construction starting on my site (401), I have spent the last couple of days on a site elsewhere on the West Gate Tunnel Project (403) where they have been installing precast driven piles. I’ve used this time to understand driving process and QA regime in preparation for similar works starting at 401.

Of interest has been the rejection of several precast piles by the Principle Contractor (CPBJH JV). Piles, as per a previous post of mine, have been cast by the piling subcontractor as part of a Design & Build Contract. I have also taken keen interest in the testing of piles and the process of restriking.

With this post, I hope to provide those on attachment with no involvement of precast concrete structures or driven piling operations with an insight to what I have learnt, and maybe get some thoughts?

Rejected Piles

Precast piles, under VicRoads (VR) 610 specs, must have a Class 1 finish. This is a durability requirement given that piles are subject to aggressive subsurface conditions. On 403, and undoubtedly an issue we will forego at 401, several piles have been rejected due to surfaces having excessive ‘blow holes’; a result from the entrapment of air during casting. The standards we work to state that blow holes over 15mm in diameter and /or 5mm in depth must be repaired prior to installation.

The issue we have is that there are no approved repatching procedures for the project. This means, under the PSR, that piles cannot be repatched and must be rejected; a cost risk held by the subcontractor but one that will delay CPBJH JV further. I’m amazed that no procedure exists and, as you can imagine, there are a lot of people scrambling around to get one in place. Simple? It would appear not. Several procedures have been submitted for approval but, after review, have all been rejected by the IREA (the Client’s third-party auditor) for being non-compliant with the PSR.

What surprises is me is that the subcontractor hasn’t just had a go at patching at their yard off the cuff given that this is their trade? Clearly this would result in a NCR (Non Compliance Report) but possibly worth the risk for them? Considering they have delivered the piles to site and are cracking on (ignore the pun) seems to me that they planned to install them anyway, and hope no one would notice? As can be seen in the picture below, the extent of some blow holes seems very minor (see pictures below). I’d be interested to know if anyone else has seen this, has experience in the matter or would have a solution that doesn’t involve weeks of submitting approvals and replying to comments prior to acceptance?

Testing and Restriking

As per VicRoads Spec 605 (Driven piles), the first pile driven in each pile group is tested and the ultimate capacity is determined in accordance with the formula used in design (Hiley Formula). The test then determines the driving set for each pile group by correlating the set with the driving system and the designer’s requirements for the pile test loads (these must be demonstrated on the design drawings). All piles within the group are then driven to a set that does not exceed the driving set determined by the first pile.

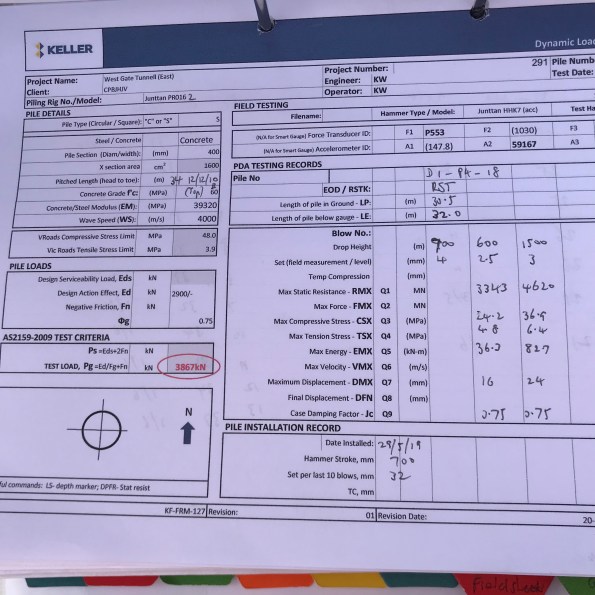

The method of testing for this project is Dynamic Load Testing (aka dynamic loading). Dynamic load testing is a method used to assess the bearing capacity of a pile by applying a dynamic load to the pile head (i.e. dropping a hammer/weight on the pile from a set height) while recording acceleration and strain on the pile head.

In Australia and Victoria State, Dynamic Load Testing, under AS2159-2009 and VicRoads 608, is sufficient to prove geotechnical capacity of a pile. The foundation bearing capacity results obtained with dynamic load tests, from research, appear to correlate well with the results of static load test, hence they are an approved method here. Piles designed to take large geotechnical design loads and are integral to a structure, are use static load testing as a preferred method; simply because they are more accurate.

A restrike of piles then must be conducted, under VicRoads 605.08, on 10% of piles in the group, not before 24 hours after driving. The idea behind this is to assess whether ‘set-up’ or ‘set-down’ of piles has occurred (i.e. pile capacity has increased or decreased over time). It appears that the most accepted reasoning for ‘set-up’ occurring is pore water pressure related (Q the many hours of John drilling Mr. Terzaghi at us!).

Effectively, as driving occurs, pore water pressures increase around the pile, reducing the effective stresses in the soil and thus the capacity of the pile. The idea of the 24 hours (minimum) time between end of drive and restriking is to allow time for these pore water pressures to dissipate back to pre-driving levels (though I’m not sure how a prescribed time can be used given that, if I’m not mistaken, dissipation of pore water pressures is a function of the soil characteristics?).

In total, 2 piles are tested per group with a restrike. The 2 piles selected are the initial pile that was tested and the pile that recorded the highest set; for those unaware, set refers to the distance the pile moved per the last 10 blows – about 32mm in this case. This ensures the pile mobilising the least resistance in the group during driving is tested (i.e. the pile with least geotechnical capacity – theoretically).

The requirement to re-strike comes about for two reasons. Firstly because, while across my site (Zone 401) it is expected that piles will gain capacity over time, it is possible that the soil might either relax or that the piles heave, resulting in pile capacity deterioration, and the easiest way to confirm that it isn’t occurring is by completing a restrike test. Elsewhere on the project (Zones 402 & 403), restrike is being used to demonstrate that piles are actually gaining capacity over time (set up), where the ground conditions involve deep profiles (31m whereas 401 toe levels are designed to 12m) of cohesive soil which will be ‘failed’ during the pile installation process and will then ‘remould’ over time to provide resistance in the form of skin friction.

The second reason is that it is required under VicRoads 605.08, which states that restrike of driven piles must occur, and not be 24 hours.

When conducting the restrike, I noticed that the Testing Engineer did not start by conducting the test with the full dynamic load (in this case a drop height of 1.5m), instead he started with 0.4m and then struck again at 0.6m before striking at 1.5m; as note, the operators messed this up and accidentally dropped the first strike at 0.9m. The reasoning for starting small is to check the pile does not crack/damage under the stress induced from the dynamic load. Clearly, if superficial cracking/damage can be seen to occur from a lower energy then they will not continue with full drop height. This I suppose is a weakness of the Dynamic Load Test in comparison to the Static Load Test – More chance of damage to piles from the fast impact loading.

PDA equipment calculates the velocity and force signals obtained from accelerometers and strain transducers attached to the pile during driving (only attached to piles being tested). Two identical accelerometers and strain transducers are attached close to the head of the pile on opposite sides and diagonally across; this allows for a better average of results.

The PDA was used to record, digitize, and process the force and acceleration signals measured at the pile head. These signals are used to estimate static capacity using the ‘Case Method’, a simplified field procedure for estimating pile capacity. PDA tests only provide direct measurements for the forces and motions applied at the pile head and are sufficient on their own and the static and dynamic soil parameters and distribution of forces over the pile shaft and toe are not directly measured.

To account for this, a CAPWAP analysis is conducted by an offsite, independent, Testing Engineer. To verify the static component of pile resistance, the CAPWAP analysis is performed on field data from a selected representative hammer blow from the PDA test record. CAPWAP analysis resolves three unknowns: the internal pile forces, pile motions and external forces. It is far more detailed than a PDA test. However, it requires expertise and experience as soil characteristics and ground water must be entered accurately; this requires judgement of the engineer.

I’ll look to get hold of the CAPWAP results and consult with the testing engineer to see how the design, PDA and CAPWAP results compare once the piling has started at 401 to further understand!

On another note, the weather is looking much better back in the U.K. at the moment – you can’t stay on the beach past 5pm now ….

This is a good blog

I’m amazed ( in even first pass ) that the Hiley formula is used still.

The rationale for only using large strain dynamic was curious

The results can be accurate ( when calibrated against static testing) It is just that static testing is expensive. In UK practice you’d have to calibrate dynamic results with static testing

IN dynamic testing the issues can be acoustic impedance ( wither pre existing cracking or if PCC piles had to be coupled to get the desired length

The CAWAP method constructs a spring model of the pile coupled by springs representing the ground. IN the computer this model can be ‘hit’ and will give a response. In CAPWAP the ground conditions are known and the soil springs are tuned such that the model behaviour matches the observed measured behaviour. The model is then complete and can speak to performance of the ground model under superstructures loads