Plate bearing test

Victoria Square Woking are currently in the process of removing the existing shallow foundations of an old car park so they can construct CFA piled foundations for the new car park.

The demolition contractor are obligated to leave site with 1) the guarantee there is no existing structure in the ground and 2) the ground is of sufficient strength to support the piling (create a piling mat)

Yesterday on site the demolition subcontractor brought a plate bearing test team onto site to ensure the sub grade was of a high enough capacity before continuing up. An intermediary test. I thought I would share the test in case any of you were interested.

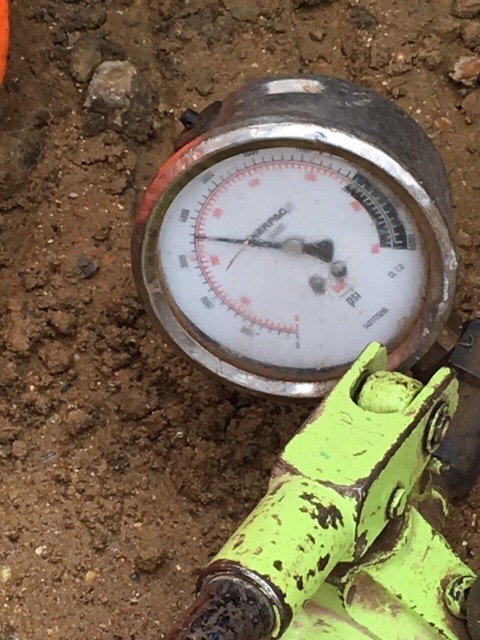

Effectively what is happening is a plate is placed under one of the excavator machines and a hydraulic jack is connected to the two. When the jack is lifted a gauge informs the operator what pressure the plate is under.

A scaffold tube is placed next to the plate with three strain gauges fixed to the plate. The differential movement between the scaffold tube and the plate offer an immediate settlement value for the plate. Once you’ve got both pressure and immediate settlement calculations can be performed to give a CBR %.

I am still awaiting the report back but the guy on site said we achieved 25% which is good considering our specification was to hit 5%

Not surprised you have high CBR values given the fill you are on. Do see BS 5390 and Plate Bearing Test BS 1377 : 1990 Part 9

The BS says they should take a sample back to the lab to determine the moisture content. I don’t remember them doing that.

How many tests did they have to do?

They are doing one at the top of the replaced fill layer and one at the top of the pile mat for each strip foundation so that’s 8 in total.

Boy this is proper old school – manual pressure gauge and, what looks like , dial gauges for settlement!

So the test is to prove the fill for plant operation; this is a bearing capacity issue and has nothing to do with CBR. CBR happens to be a strength test but is bot a bearing capacity assessment. There is the same confusion in on of the PAMs

IF the fill were being used as a pavement sub-grade or sub base we use CBR and it is linked therein with the fatigue resistance of low stress cyclic loads

Let me quote form the BS Richard refers to : ‘ The in-situ CBR (4.3) is generally concerned only with pavement design and the control of subgrade construction of soils with a maximum particle size not exceeding 20 mm.’

So in the same document we have a CBR test ( in situ)- there is a laboratory based one;and a plate load test and they are for different things

The reason the moisture content is measured in CBR testing is that the compaction associated with the fill has an optimum m.c. with which max dry density and therefore max CBR can be attained

The plate loading test is a direct bearing capacity test and can be used for:

a) settlement assessment at working load

b) us failure of a static foundation

For plant it is generally b) that is sought

So here we have a test specified without the understanding fo the risk that is being managed and without a clue on what the test is actually trying to establish

At CBR of 25%- yes all good but , if you wanted to know this you’d have to be using it for pavement design and the m.c would need to have been taken

John. I have received the report back and it tells me both the CBR AND an average bearing pressure at 1.25mm penetration. From what you said- the latter is the most appropriate value and taken forward to compare with the specification (where I can find no reference to a bearing pressure at X penetration)?