How to demolish around a live substation

Demolition on my job at Victoria Square, Woking is now almost complete. The demolition sub-contractor are in the process of removing the existing strip foundations, backfilling and creating a piling mat with the site won crushed concrete from the demolished structure.

We have a few risks regarding the interface with adjoinging structures such as the live shopping centre and adjacent construction but none are more sensitive than the live substation on footprint of our demoliton.

The substation was part of the ToyRUs on the first two levels of the previous structure but feeds a large propotion of the shopping centre and therefore must remain live. UKPN who own the substation have dictated that no vibration above a PPV (Peak Particle Velocity) can be achieved above 5 mm/s and there is a vibration monitor fixed to the substation to ensure this.

The problem is the substation sits on the foundation we need to remove and we are creating a signifficant amount of piles and substructure very close to the extent of the walls.

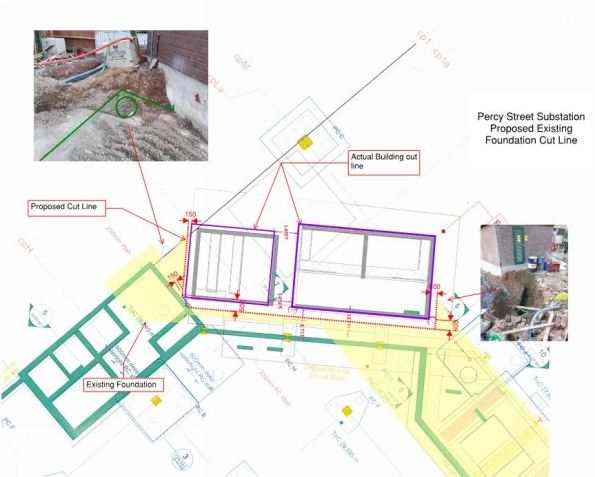

The yellow designates the foundation to be removed and you should also just be able to see the ground beams, pile caps and piles being installed in the coming months. There was the added complication that the exact location of the substation was slightly off during the design of the new structure (compare the grey lines on the drawing to our overlaid purple lines) which make these tollerances even tighter.

The vibration of installing piles so close to the substation is being mitigated by use of a CFA method (although this was always going to be the chosen method anyway as it was selected for the rest of the site) but it still leaves the problem of breaking out a 1.5m deep reinforced concrete foundation 150mm from the substation which isnt allowed to experience vibration. The solution…

Diamond stitch drilling. By using a 150mm diamond drill bit and drilling along a given line around the substation overlapping the holes creates a seperation of 150mm of the foundation under the substation and the foundation to be removed. This is an incredibly slow process with each driller completing less than a metre a day each. With 4 operators on site this will still be nearly 2 weeks work.

In the photo you can see 4 drill rigs set up as the drill out cores of the foundation. It hasnt been raining that soggy foundation is caused by the amount of water used to keep the drill piece cool.

I still have my reservation on whether this will prevent vibration when it comes to removing this foundation considering I feel it in the site office, but it shows we are taking practicable measures to comply with UKPN targets. Whether UKPN have set unreasonable targets is a question for another time I guess, a quick bit of research told me that structures can normally resist up to 20mm/s but I dont have a full understanding of sensitivites to generators or transformers that may be inside.

Thanks Ash, I’d suspect very few issues with equipment and the occasional shock or bit of vibration but that won’t stop an E&M putting a silly limit on it if they think they can get away with it without having to think. It would be interesting to ask about the basis of the limits and see what comes back.

Has any though been given to stitching about Dx1.5 apart and then splitting the slab by bursting with hydraulic pressure or expanding grouts? It would reduce the drilling time by at about a third.

I did ask our environmental manager about the basis of it and was told “cos that’s what we’ve been told” which means she didn’t know and didn’t like my tone. This was why I asked the question at the demo lecture last week to their environmental chap and his response was it’s just a standard limit for different receptors. The only research I’ve found states that statistics and experience has shown structural damage to buildings happens above 15mm/s but couldn’t find much else.

I did research a couple of these methods when they were doing the drilling (we all had the time to considering how long it took) and I think ultimately the answer was the demo subbie who subbed it out always use this company and wanted to keep using them. Time wasn’t a critical driver in this particular area so there wasn’t any need for them to think outside the box or look for another solution.

The issue isn’t so much the building itself, more the large amount of copper and associated enclosures that are all held together with bolts, screws and the like which could cause quite an interesting light show if they started to separate!

The maximum vibration allowed is 7mm/s according UKPNs standards (EOS 07-0118), assuming the vibration effects have a non linear response would the extra 2mm/s help you?

I think it would. However, the appetite of our environmental manager doesn’t seem to be to push back with a counter offer. I think UKPN will probably know their actual limits and when we have crept over ours they have not raised any issues because they know they have some wiggle room between the two.