Return of EFC

For those who have read Tom’s blog about EFC this is just a small addition as you can’t add photos to comments it needs its own post. For those who haven’t read Tom’s either go back and read it or ignore this one as I won’t waste time regurgitating what he articulated better than I could and it won’t make sense unless you have.

Basically BAM sent out a message to us temporary works designers encouraging us to use EFC in our designs. It seems that due to lack of codes or experience with it they are not confident on recommending it to larger permanent jobs but they think the temporary works environment is a perfect start for its incorporation. We have been sent both Wagners (Toms post) and CemFree brochures to read. They both offer similar properties and savings.

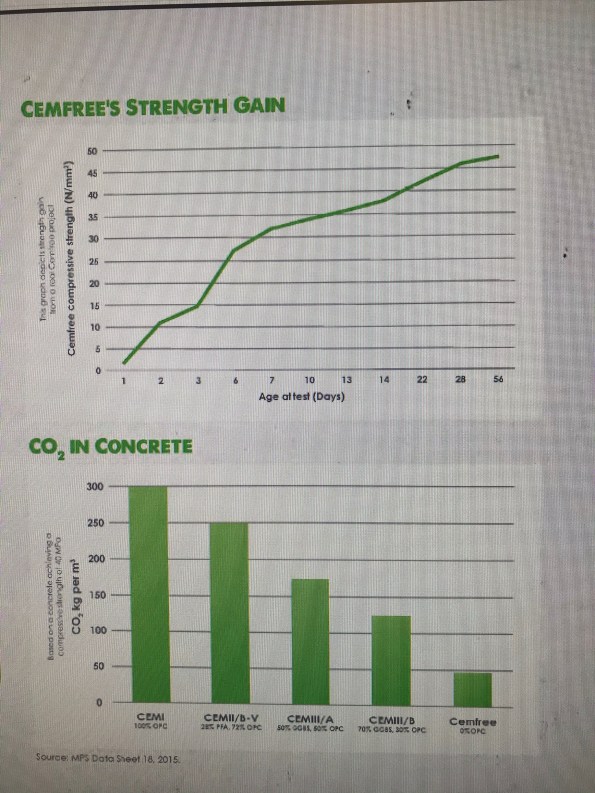

That is the strength and savings promised by CemFree for their product.

The fact BAM have suggested it for temp works first is either due to the lack of risk on our designs (perhaps due to the perceived inefficient low risk designs produced by temporary works designers) or maybe they have worries about its durability.

CemFree advertise a coastal defence job used in Harwich using 100% EFC saving a staggering 88% in embodied carbon, they clearly have no such worries on durability.

I do wonder if the H&S of using AACM instead of cement powder is advantageous as well as there is no mention of the dangers of its powder form on either companies brochure.

Great post Ash, a really interesting topic thread developing here. What are the COSHH implications of this stuff in powder form please?

It’s great to see this stuff (or at least the concept) gaining traction. It does seem odd to me though that BAM are reluctant to use it in permanent works. As with all things, there will be applications for which it is not suitable but drawing that line arbitrarily between temporary and permanent seems short sighted. In real terms, temporary structures are just as able to kill people when they fall over.

On the codes: the only codes I can think of which may not apply to this are those regarding mix design and constituent parts. The base codes (resistance > effect) clearly still apply and EFC has known characteristic strengths which can be applied using the Eurocode approach.

In contrast, Keltbray are trying to push EFC for piling (permanent), for all the environmental benefits as well as some very good chemical resistance properties. Wagners released a case study on EFC in sewer tunnels advertising its resistance to sulphate, chloride and acid attack – ideal for piles in potentially contaminated soils. CEM-FREE are obviously saying the same with their Harwich example. Maybe the inland maritime arena can make some good use of this?

This is not to say there is no longer a place for OPC anywhere, and there is certainly a lot to learn about EFC still, but perhaps BAM (and anyone else not looking at similar products) might push the boat out a bit further…

I don’t think the line between temporary works and permanent not structure is drawn on the basis of probability of structural failure resulting in death, more that there is risk aversion to working with a new material (although I content this is nothing new). The drawing of the line is to allow learning to take place within a risk environment that is in the control of the contractor so there are no external claims under the contract, any issues can be addressed and impact on programme absorbed. I suspect a similar absence of issues surrounds piles because of the challenge in seeing them!

I am surprised by any ‘stir’ around this as a concept. CEMIII/C is defined in BS EN197-1 as a common cement, it is up to 95% GGBS and also falls in the sulphate resisting common cement category. It is used in piling because of the resistance to aggressive chemical environments and ability to be useful with gradual strength gain at a rate faster than the speed of construction of the finished structure above. The more challenging applications are elements such as pre-stressed, post-tensioned slabs where properties like elastic shortening and creep are important. I suspect similar challenges in pre-stress pre-tensioned components when early strength gain helps with striking time as well as concrete losses.

I note the plot of strength gain provided is a single uncontrolled example from ‘a real project’, which is extremely dubious and says nothing about the designed performance, conditions under which performance was recorded, statistical reliability or repeatability. Fortunately I know you wouldn’t use this stuff without transferring all of these risks to the supplier and double checking their insurance details first.