Powerhouse

Thought I’d share an interesting and beefy mechanical services problem I’ve been landed with over the last few weeks.

Following a successful competition bid, I have been placed on the ‘Powerhouse Museum’ mechanical services team.

The Powerhouse is a new event/museum/art space project (think a mix between Science Museum and the NEC) that forms the ‘largest investment in culture and the arts in Sydney since the Opera House’ and has a budget of around AU$400m.

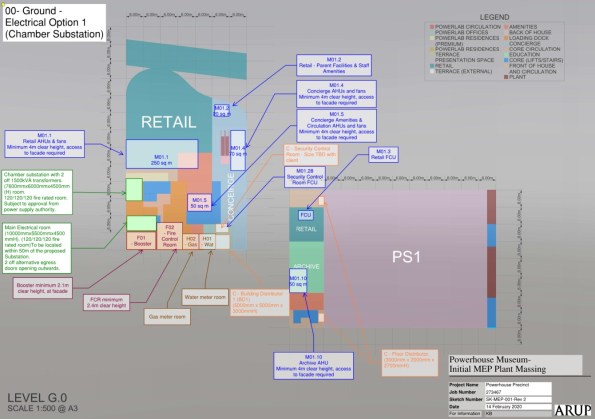

We’re at the very early stages of design and I’ve just finished knocking out the initial space conditions appreciation for the internal space in an attempt to provide some plant massing figures for the air handling plant.

All I’ve had to work with is a rough layout from the architect, depicted on ‘Rhino’ (coloured blobs depicting rooms/areas) and a very ‘strategic level’ project brief.

It quickly became apparent that there are some significant issues with what the winning architect wants, what is physically possible and what the Client (Govt. of NSW) can pay for. Not only has the building envelope shrunk by 30% whilst the expected space populations remain unchanged, the control level for the spaces is to the ASHRAE ‘AA’ standard (rigid temperature and moisture control to protect sensitive artwork).

Helpfully the architects have allocated less than 1% of the floor area to plant space and are appalled that we may request more. Considering the location (summer 40+ degrees and high humidity) and the fact that the façade is all glass…my numbers are coming out silly sized!

Taking the largest presentation space as an example – the space is approximately 3000m2, with a floor-to-ceiling height of 30m. Current plans have this space with a peak population of 5000 people (0.5m2 per person).

I’ve had to make some pretty savage assumptions to ensure the entire structure isn’t just filled with plant:

- Firstly, the assumption that the population will reduce, so I’ve been modelling at 50% occupancy relative to the original value

- Secondly, we will only be treating the lowest 4m of the room

Even with this, to ensure minimum indoor air quality I need to deliver over 40m3/s of cool air to the space. This OA requirement, coupled with the estimated heat gains, sees a cooling load in the order of 1.4MW; and this is one of seven presentation spaces.

Another big issue is how we deliver the cooled air to the space. With a 30m high space, the means of controlling the mixing with the layer above 4m, which will have its own humidity, temperature and stratification presents a problem for control. ‘Top down’ delivery sees the air thrown 26m before it reaches the 4m layer to be cooled. I conducted a benchmarking exercise against other museums, which seem to favour floor level grills. These require thicker walls for the ductwork – however the spaces they are used are kept relatively small and are located at the core of the building to assist the plant.

What is inflating the numbers is the rigid control class and the population – these are our first targets to ‘manage’ with the architect. I get the impression that this is a once in a lifetime/legacy project for them and the museum curators; as such they’ve asked for all the bells and whistles.

Thankfully, the Client has appointed Arup directly – so there’s some leverage to play with when interacting with the JV of French, Japanese and Australian architects!

Does anyone have experience of controlling temperature in very large spaces? I’m thinking that airports will have similar volumes, albeit with more flexible control regimes. Can you throw air that far, still maintain control and not ruin the comfort conditions with the effects of draft?

David, the use of convective cooling in a space with a high roof is analogous to the heating workshops problem I used as an example during the heating module. One of the answers to this problem is to use very high velocity and extremely hot air streams that are designed to entrain the air that they are injected into, so that by the time the streams reach ground level, the air is at the right temperature. The entrainment and tempering of the air in this manner is considered to be reasonably cost effective and if the nozzles are high enough, noise shouldn’t be a problem. Using super chilled air could achieve the same effect. The heating example of course doesn’t require humidity control and I am not sure how you would do this accurately using this technique.

How about using a chilled floor to deal with the sensible load and a much smaller convective system to deal with the latent energy and humidity? The wall facings and window treatments will also greatly affect the eventual load you have to cope with. Polished concrete or marble would be good. There was also some talk about using phase changing materials to sort the Denison Block sweat box problem back in the day, but these got taken out of the design on the grounds of cost. Passive measures such as these will significantly assist with reducing the size of the eventual services that have to be fitted. As another thought, how about using some form of absorbent material to remove the latent load and control the humidity? Arup’s research people must have come across similar problems to this on past commissions. Do you have reach into their services?

Thanks Jim. It’s definitely turning into an interesting problem. We’re still at the early stages, so at this stage seem to be using these large numbers to bludgeon the stakeholders into accepting more realistic space conditions.

Arup do indeed have previous experience in this field and we are reaching out to the global offices for advice. Arup were involved with the Tate Modern, V&A, Western Australia Museum, Natural History Museum and a number of high profile US museum projects – I’ve just finished up a benchmarking study that we are to present to the Client/curators to massage them into line.

I forgot to mention that the main presentation space has a full length, glass hangar door that they can open for major events. We haven’t even considered the infiltration load of the air sneaking past this closed ‘mega door’.

Fingers crossed they relax the control class and reduce the expected population so we can work with some sensible numbers!