Archive

The cost of Covid19 to HS2 – £1 Million a day

A friend of mine who works in insurance sent me the article below which I thought was interesting. It talks about the industry’s concerns about which clauses an insured might make a claim under due to Covid-19. It sounds like construction companies will have to pay extra for ‘disease extensions’ for policies in the future.

Has anyone had any insight yet as to what insurance companies are saying to your construction companies? With HS2 so large we’re looking at delay costs of around £1Million a day, the piling on my site is £30k a day alone and the insurance picture is unclear.

The Article

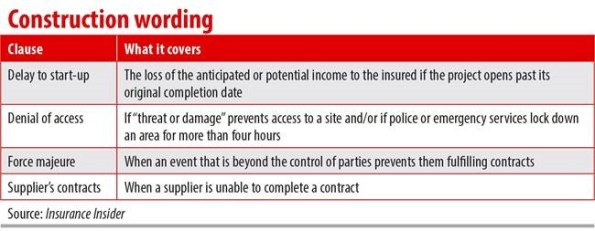

Vague construction wording could give rise to Covid-19 claims

The construction market is bracing for debate around Covid-19 claims as several wordings could be used by insureds to make a claim, Insurance Insider understands.

London-based sources told this publication that there will inevitably be delays to projects currently underway – with some sources giving estimates of six months or more – meaning policies would have to be extended. New projects that were due to start have now been left in limbo due to the coronavirus crisis.

While it is too early for loss notifications, construction underwriters are scrutinising wordings which could leave them open to potential losses that would threaten the class’ recovering profitability.

“We are in totally uncharted territory. We are in survival mode, we have to just get through the next two to three months,” one source said.

Rates in the construction market had been going up by 20-35 percent following high loss activity and a number of exits over the past 18 months including Beazley, Brit, CNA Hardy and Talbot, with a range of others passing through remediation exercises.

Delay to start up

One area currently under the microscope is a delay-to-start-up (DSU) clause, which is designed to cover the loss of the anticipated or potential income to the insured if the project opens past its original completion date.

However, sources told this publication that this clause’s trigger is typically physical loss or damage, and that it was not typical to have an infectious disease trigger, however the peril could be sub-limited.

One source added that, in the UK, infectious disease was a “standard or common” extension, so the UK may be disproportionately impacted.

Sources added that insureds typically have to wait until the scheduled completion date to make a claim, meaning there could be a time lag for claims.

Insureds can only claim under this DSU clause once, meaning they would have to buy this cover again – and possibly at an increased price.

Denial of access and force majeure

An additional area of concern is ingress or egress clause, otherwise known as denial of access. This wording could possibly warrant a payout, with one version of the clause implying that an insured could make a claim if there is a shutdown due to “threat or damage”.

Another version states that if emergency services or police have prevented access for more than four hours to a site, that could trigger a claim, even though it “wasn’t designed for this”, one source noted.

Force majeure wordings are also being examined by underwriters – where an event that is beyond the control of parties prevents them from fulfilling their contractual obligations.

Sources told this publication that, typically, force majeure events are specified in the construction contract, but some said coronavirus could be classed as a force majeure event, therefore making insurers liable.

There are various ways to invoke force majeure clause: a government mandate to cease construction, or prove that the coronavirus outbreak had caused one of the events on the list such as travel bans. The party would have to show that the events have impacted its ability to fulfil its obligations.

It was suggested that projects which relied on global supply chains were also struggling. This instance could be covered under all-risk or specific peril cover via suppliers’ contracts, but it is typically difficult to claim under, sources said.

Insurer actions

To combat uncertainty, insurers are introducing clarifications and exclusions on new business, but this is not universal across the sector.

“Some insurers are being slower than others to introduce the exclusions on new business. We are not looking to change existing contracts because that would be suicide; it would be stupid to go down that road. We are just looking at taking out disease extensions or making it clearer,” one source explained.

Overall, sources said the insurance sector was going through a “great period of uncertainty” and the picture globally was mixed, with some sectors stopping construction completely whereas others like the UK are allowing construction to go ahead.

Sources noted that risks were still getting bound and prices have gone up month on month for the past 12 to 18 months. This is set to continue, they added, and suggested it would be sensible for insureds to secure cover now before a potential price jump after the crisis.

There are still fears over the pipeline of new business as project financing is withdrawn by banks and lending is put on hold.

However, some underwriters were optimistic about stimulus packages, such as Donald Trump’s $2.2tn stimulus bill that was signed on Saturday, which could create jobs via new projects or infrastructure upgrades.

Covid-19 Response; Temporary Hospital Design (Exeter)

You will all be familiar with the extraordinary efforts currently going ahead to complete the 4000 bed NHS Nightingale Hospital in London. Although on a smaller scale, my design office has just been stood up en-masse to provide designs for a 500-bed facility in Exeter. Whilst waiting for the URD to be issued, we’ve all been briefed to familiarise ourselves with the requirements specified in the document:

Having reviewed the document and other relevant sources*, I wanted to give a bit of an overview of what is required from an E&M perspective, as I think the design considerations would be of particular interest in the current climate.

All Patients with suspected or confirmed COVID-19 should be placed in single rooms as shown below.

The following design requirement/ considerations are per treatment room;

Medical gases:

- Patients will need continuous medical care using piped medical gases.

- The design must be factored around the source of supply; bulk liquid oxygen plant/mini tanks/portable cylinders.

- Medical oxygen supplies must achieve a flow rate of 10 L/min, per bed (implied task; check and confirm all distribution pipe sizes).

- Distribution systems must alarm if pressure drops below 3.85 bar

- Medical air manufactured using compressors on site. It is required for driving ventilators and is supplied via a dedicated pipeline system. In addition, medical air cylinders are normally used as an independent back-up supply.

Fire:

- The use of ventilators will result in increased oxygen levels with increased risk of combustion, which should be factored into a fire risk assessment.

- Temporary fire-stopping should be provided for any wall or floor penetrations.

- Automatic smoke detection is required

HVAC:

- The density of ventilators may enrich the air with oxygen, increasing the combustion risk. To mitigate this risk the level of air changes through natural and mechanical ventilation must be maximised to lower the oxygen level to <23.5%

- Where locations are considered “early stages” or “high-risk”, patients with COVID-19 should be isolated in “negative-pressure rooms”. The recommendation is to use portable suction units which can be removed and sterilised.

Small power:

- Each treatment room requires –

- 4 x twin 13A switched sockets

- 1 x 13A cleaners socket

- Each room has a number of electronic equipment, including ventilators, for which the combined loads will need to be calculated. Diversity will be minimal as all systems will run at the same time.

Lighting:

- Each treatment room requires –

- 20-20 lux general illuminance for night-time

- 1 x 1000 lux adjustable examination lamp

- Emergency escape route lighting required: In accordance with BS 5266 and HTMs.

Domestic Hot and Coldwater:

- Each treatment room requires a hand wash basin, which should be fed through a mixer tap.

- Max hot temp = 41 dec C

- Max cold water temp , 20 dec C

- Max pipework surface temp = 43 deg C

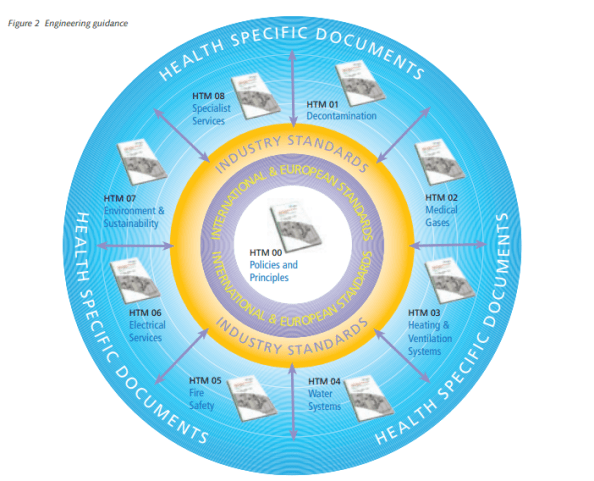

The above detail is just taken from the one document, but the HTMs go into much more detail and will provide the basis behind any designs.

I’m sure you’ll agree there’s quite a lot to think about there… and I’m looking at 500 beds, not 4000! As a standard project, on standard timelines, all of this would not be too challenging but when considered this is all to be completed within 10 days, you can imagine the challenges with design, supply, installation and commissioning. Not to mention the unprecedented level of collaboration and coordination required.

Although the treatment room designs can be replicated for each room, the distribution and containment networks for small power, lighting, water and medical gases will require careful consideration.

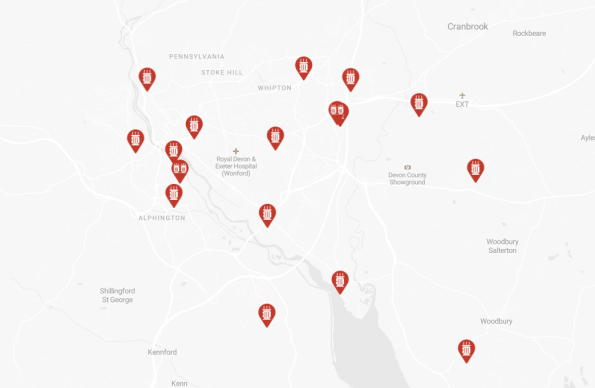

A major consideration will be the availability of supply from the local utilities companies and medical supply chains. The newly appointed site would have a much higher usage of water, electricity and gas. It will be important to calculate the requirements and engage with the utilities companies to ensure that the demand can be met. I know from recent experience that Exeter does not have a great deal of spare capacity in the electrical grid as shown below;

Hopefully, this has been of interest and given you some insight as to what is expected, with what I suspect might be the first few of many of these sites.

*A list of all relevant Health Technical Memorandums (HTMs) and Health Building Notes (HBNs) can be found on the UK Gov website HERE, but as a rough guide;

Virus stops play

Following on from Colin’s blog about the contractual implications of tightening restrictions on non-essential travel around the world, I thought I’d start a thread for any interesting updates on the impact to us all. (Here is the NEC article I commented about but couldn’t link).

Phase 3 for the most part are able to work from home to a greater or lesser degree but how is it affecting Phase 2? And how much work will there be for design offices, especially the temporary works houses, if on site activity dries up?

My main site in the City has closed today but the project team are still active from home and they haven’t mentioned any intention of slowing down on the planning side so all is still go here. I have heard of one or two smaller projects in our office cancelling design work but as of Monday morning we have a full workload for the whole office – we will see how long that lasts.

It has been interesting in London to note the political views on construction as ‘key workers’. The PM seems to think construction counts as worthwhile but the Mayor of London not so much. It seems agreed however that national infrastructure projects will be allowed to continue so anyone embedded in Tideway, HS2, Crossrail, Highways England, (Hinkley I imagine?) etc should have a chance to keep some money trickling in.

Coronavirus contract webinar

I was provided the following link to a Coronavirus contract webinar (1 Apr) from Turner & Townsend who are quantity surveyors for one of my work’s projects.

Everything I have seen so far seems to suggest that it is likely companies under JCT will seek a force majeure event, potentially receiving additional time but not money. Under NEC it looks like clause 19.1 – prevention. This being an event which stops the completion of works on time, that that could not of been prevented or foreseen. This would link to a compensation event under clause 60.1(19).

The Built Intelligence website seems to have quite a few other interesting free resources which could help people looking for some CPD.

No longer being on site it is harder to get a handle on how the issue is being dealt with. It would be good to hear what other people are experiencing.

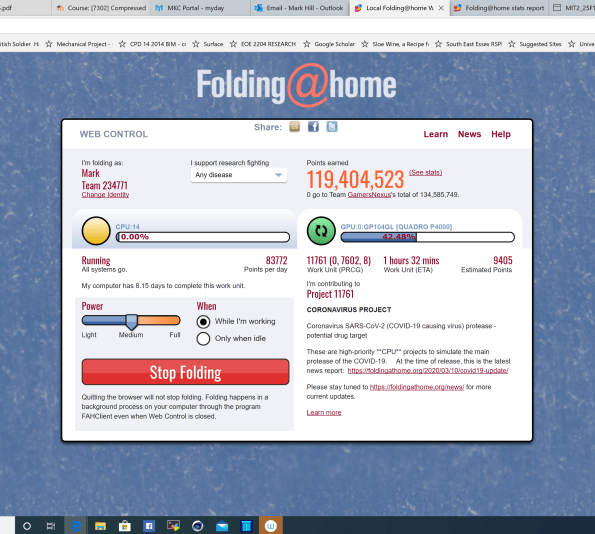

Distributed computing

Off topic for the blog but on topic for the current climate. For those of you writing up your thesis and other academic work then why not consider using your spare computing power to look for the achilles heel of COVID-19?

I’ve signed up to folding@home – a distributed computing model that utilises spare CPU and GPU power , why not give it a go? All you old bitcoin miners out there dig out the rigs and put them to use again!!

Government Approved Blogging?!

After a week on site at Martin Place Station, Sydney I have an interesting topic (rock reinforcement) for a blog. However, upon approaching my PM, I have been initially advised that all project related comms need to go through the client – Transport for New South Wales. The process can take up to a month or so. Has anyone else had such problems previously? Any advice would be appreciated.

Happy Sunday all.

Technology in Engineering

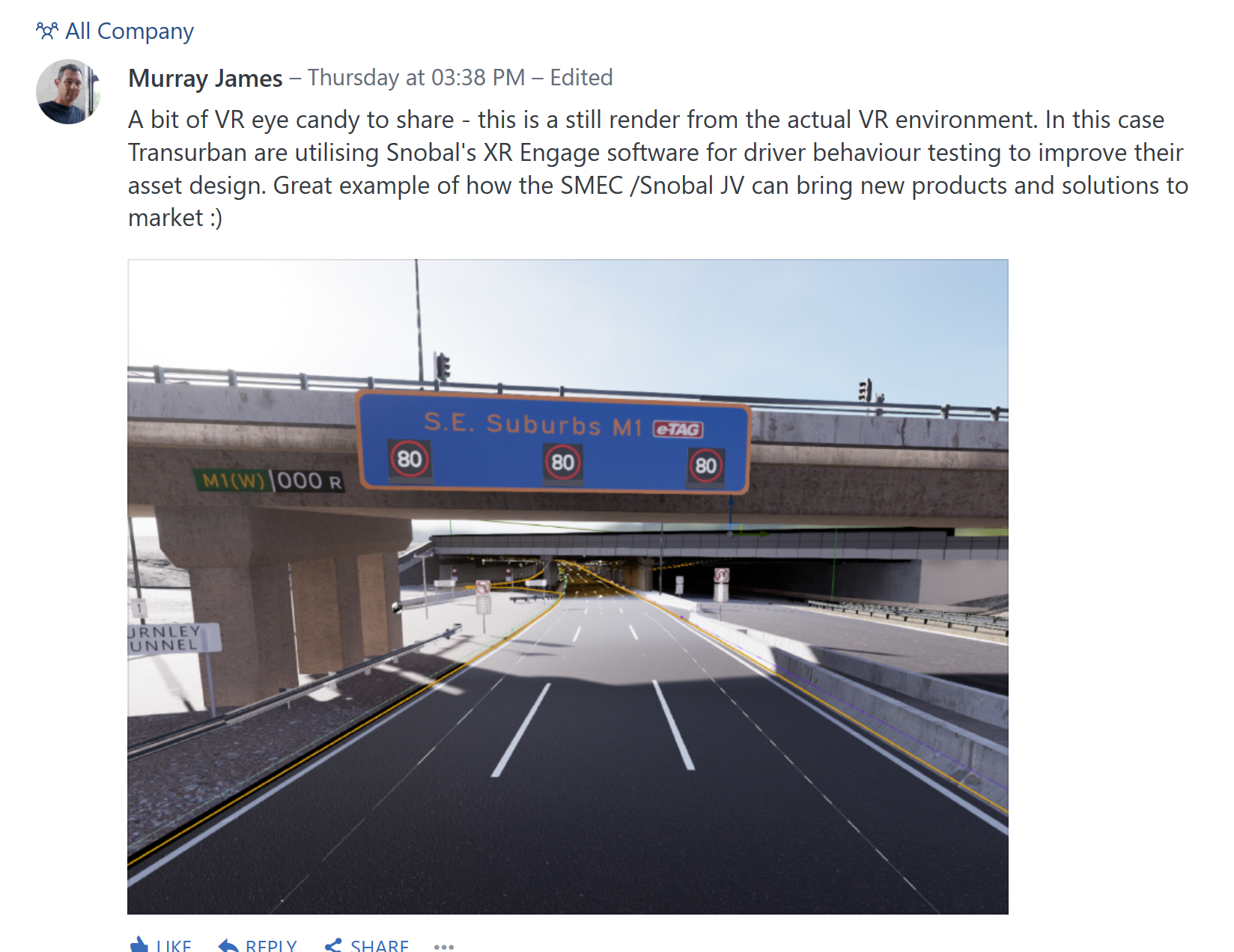

Tom I remember you asking about companies using VR technology. Below is a still from SMEC’s internal blog.

The image is a still from a VR model developed by Snowbal’s programmers as part of a JV with SMEC to push the boundaries of their current VR technology. From an inital glance it looks pretty convincing.

We have a team of programmers based in the office as well as VR technology including a driving simulator (think arcade racing car set up). This enables Clients to get a immersive VR presentation of a design or for the engineers to asses and improve different design options.

I can see this being really useful for highway/rail/building and services design. Is anyone experimenting with this on Phase 3?

History vs Modern Needs

Did anyone have any interesting issues thrown up during their phase 2 relating to historical artifacts or heritage? We had a few items discovered on my Batemans Bay project.

A key part of sustainability is reducing the negative impact of our engineering on society. I remember Dave and Tom providing earlier blog posts discussing the reuse of building facades vs entire reconstruction. On Sunday I came across this gem so thought I’d share. Sorry for the double picture but I couldn’t get it all in one shot.

This is a historic building that used to be a lead pipe and shot factory that now sits inside one of Melbourne’s shopping centers that is built above Central Station. Clearly there was some kind of preservation order on the building so the new construction was built around the old to preserve it and transition to commercial use. I’m sure there were contamination issues to overcome but an interesting way of preserving the building for the future.

Geology on the Western Front

Another topic on geology; this time lack of geological appreciation during WW1.

The Germans took the initiative in utilising geology to influence planning, but this was not until 1915, despite the efforts of Walter Kranz, a German fortification engineer. Through his efforts, by the end of the war 250 geologists were trained and placed in the front line directly supporting troops. The problem was their low position in the chain of command.

The British did not appoint their first geologist until it was identified that there was a need for clean drinking water. Lt King, originally serving with the Royal Welsh Fusiliers, was placed in the British General HQ. The advantage of this was his advice was heard at the highest level and he could influence strategic planning. But military geology was not taken seriously until mining became important and then the most senior geologist became Major Edgeworth David, Professor of Geology at Sydney University. By the end of the war, there would be 5 geologists in the HQ.

The biggest contribution the geologists made was to the mining. The biggest success being the attack on Messines Ridge, where 19 mines were exploded on 7 June. This contributed to a significant advance of the allied front line. The reason for the success was tunnelling expertise and the Blue Clay that the British sat upon. Whilst the clay produced significant issues with ground water in the British Sector, impacting on above ground mobility, it enabled the British to dig deeper than the Germans who sat on sand fed by an underground aquifer; the Kemmel sands. This provided many challenges to their mining.

The devastation caused by the mines is best shown in the pictures below; mines at spanbrokmolen (pool of peace) and Caterpillar crater.

The success of the mines would not have been achieved without geological understanding. Geology also had a part to play in water supply, drainage and resources. Plenty to consider next time you listen or contribute to a ground brief; think underground as well as above ground.

What is 3D geology modelling?

Aurecon regularly put on ‘Lunch & Learn’ sessions for their engineers. This is a great opportunity to here from other areas of engineering and hear about some cool engineering technologies being used across the company – yes, I used the words ‘cool’ and ‘engineering’.

Recently, an engineer from the geotechnical team delivered an interesting presentation on 3D geology modelling and it’s use on large infrastructure projects. As I am working in the bridge design team, I decided to go along and get some time away from superstructure ‘stuff’.

3D geological modelling is a key ground engineering technique, which is increasingly being utilized on large and medium sized projects, particularly for large linear infrastructure projects (think tunnelling and mining). Over the past two years, Aurecon has aligned to the use of the software ‘Leapfrog Works’, although a range of software applications exist. This was of interest to me, as I know it was used for the West Gate Tunnel Project (WGTP).

3D geology modelling is transforming the way ground engineering data is acquired, analysed, and communicated. Some of the key advantages are:

- Improved ability to compile large ground information datasets, which in turn improves the way you can capture and communicate geological complexity;

- Enhanced data visualisation, which aids with interpretation of ground risks and improves our ability to detect problems with input data or with the ground model;

- 3D geology modelling is visually engaging, which can enhance client or stakeholder presentations;

- Improved process efficiency and semi-automated section production;

- Dynamic integration with centralised ground investigation databases, allowing for rapid propagation of changes and revisions

- A centralised, online environment, that enables improved collaboration on modelling projects and allows for tracking of changes and improved model QA.

On the WGTP, 3D geology modelling (using Leapfrog) was used for the 6km of tunnels and supporting road upgrades to determine spoil volume, of which the Leapfrog model anticipated to be over 2 million cubic metres; this included earth and rock spoil material. This ability offers clear advantage for tendering purposes; how many spoil trucks will I need, etc.

In addition to this, it was also used to: highlight risks at the portals, model aquifer units used in hydrogeological impact studies, generate 2D sections for geotechnical ground movement modelling and was key for communicating risks/design to the client.

However, GROUND IS RISK!!!!!! (as a pen flies across the room towards Mr. Dale)

Like anything within the dark art of ground engineering, there is some considerable risk involved. 3D geology models do not just ‘magically’ understand everything about the ground and, like any software, require information input. Models are generally built from borehole data, ground investigations, etc. Therefore, most of the model will be based on interpolation and assumptions of ground conditions based off the data available.

Ultimately, clear communication of uncertainty remains a major risk, and the importance of good geological expertise is paramount when using 3D geological modelling. But the process and softwares available clearly offer a powerful tool for modelling and understanding the potential risks.