Using polystyrene as a structural filler replacement

Recently I’ve finished the installation of a welfare facility for a package of works I’m currently managing. One of the few outstanding tasks was to pour a very simple 100mm concrete footpath with a bit of of A193 mesh in the middle for cracking protection. The footpath was to surround the perimeter of the welfare facility.

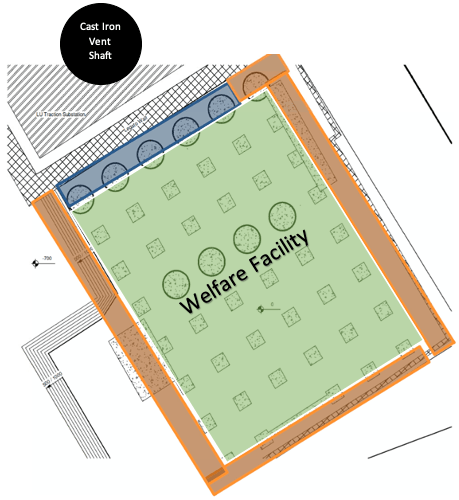

However shortly after installation, the temporary works team contacted me to say that their calculations for the welfare platform had been Category 3 checked (the highest level of check, conducted when there is a high risk to a third-party asset) and had failed. It failed on the basis that the crush (6F2) platform on which the footpath was going to sit was exerting too much pressure on the adjacent cast iron Victorian London Underground vent shaft and could lead to a catastrophic failure. Consequently the temp works team said that the platform needed lowering along one side of the welfare facility (see diagram below – area to be lowered in blue.).

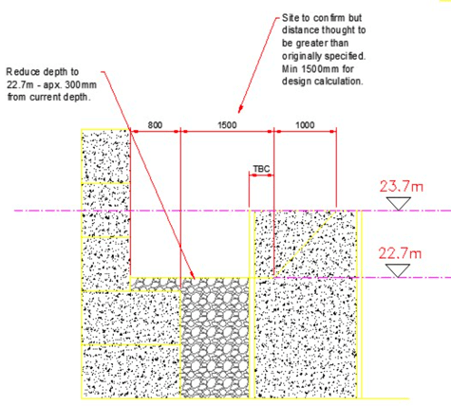

The platform needed lowering by about 1m over a 20m length to reduce the loading on the vent shaft – by removing 20m3 of 6F2 crush we would be able to reduce the loading on that area by about 48 tonnes. The sketch below shows the requirement to lower the platform from 23.700m to 22.700m.

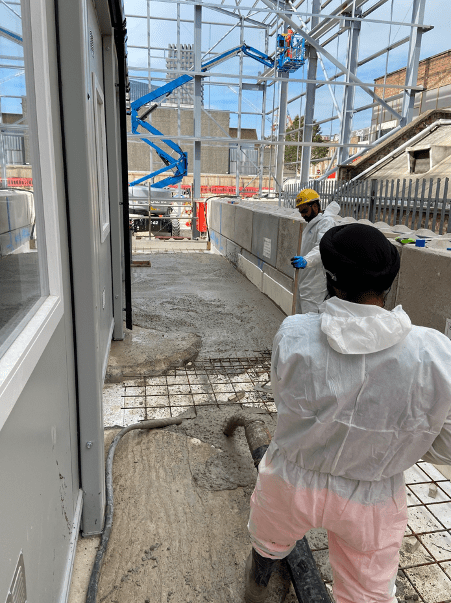

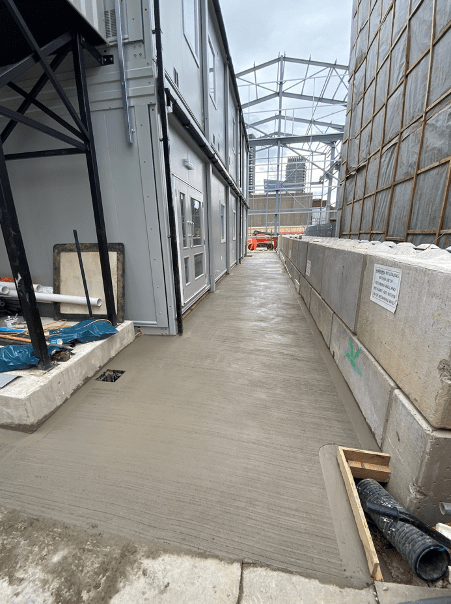

The photos below show the reduction of the welfare platform level.

Back to the footpath. I now had to install a footpath over a perimiter that over a 20m length had dropped by 1m. We considered 3 options:

- Build the platform back up to 23.700m with a scaffolding solution (not permanent enough and would be a burden for the weekly temp works checks).

- Drop the footpath down to 22.700m with either a concrete or Haki staircase (not DDA compliant and restricts maintenance to this north west side of the welfare facility).

- Build up the platform to 23.700m with a light weight material. (this is the option we selected).

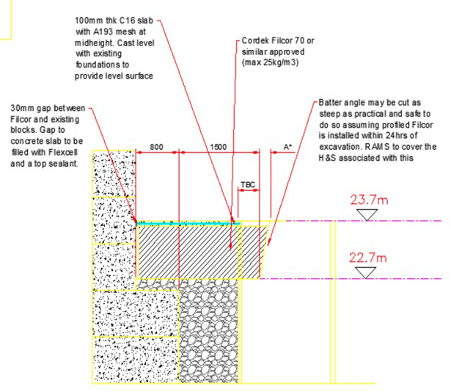

The foreman mentioned that he’d seen polystyrene being used before as a lightweight filler and although no one else in my team had any experience with it, it was proposed as a solution to temporary works who signed off the design (see below).

Filcor 70 is an expanded polystyrene with a density of 25kg/m3 and a compressive strength of 70kPa – plenty enough for us (although Filcor’s products go up to 190kPa, see link: https://cordek.com/products/filcor).

The photos below show the installation of the polystyrene followed by the concreting and finished footpath. I hadn’t heard of using polystyrene as a lightweight structural alternative so it might help people solve similar issues in the future – one to bear in mind.

My Phase 2 project had a similar challenge to overcome in designing the access ramps, corridors, service ducts, drainage falls, etc in the Level 00 loading bay and service areas which were on the roof slab of Moorgate Underground Station. In order to minimise the weight of concrete all the levels were made up with Cordek products (various, depending on load capacity and thermal properties) with only the minimal layer of concrete on top. Sadly I never got to see those pours take place so good to see it here in practice.