My biggest fan – 15min read

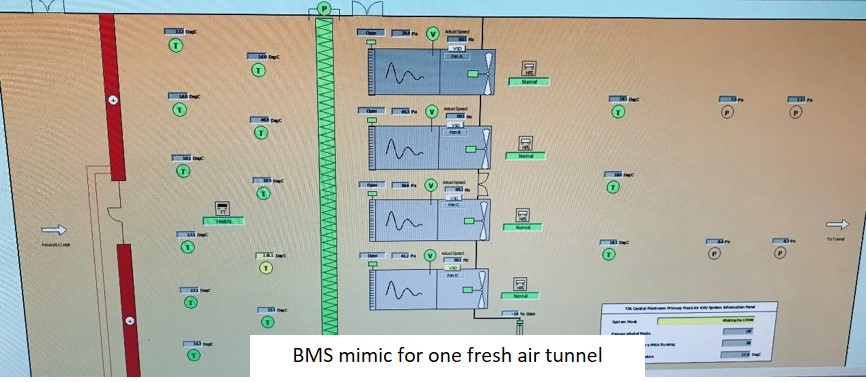

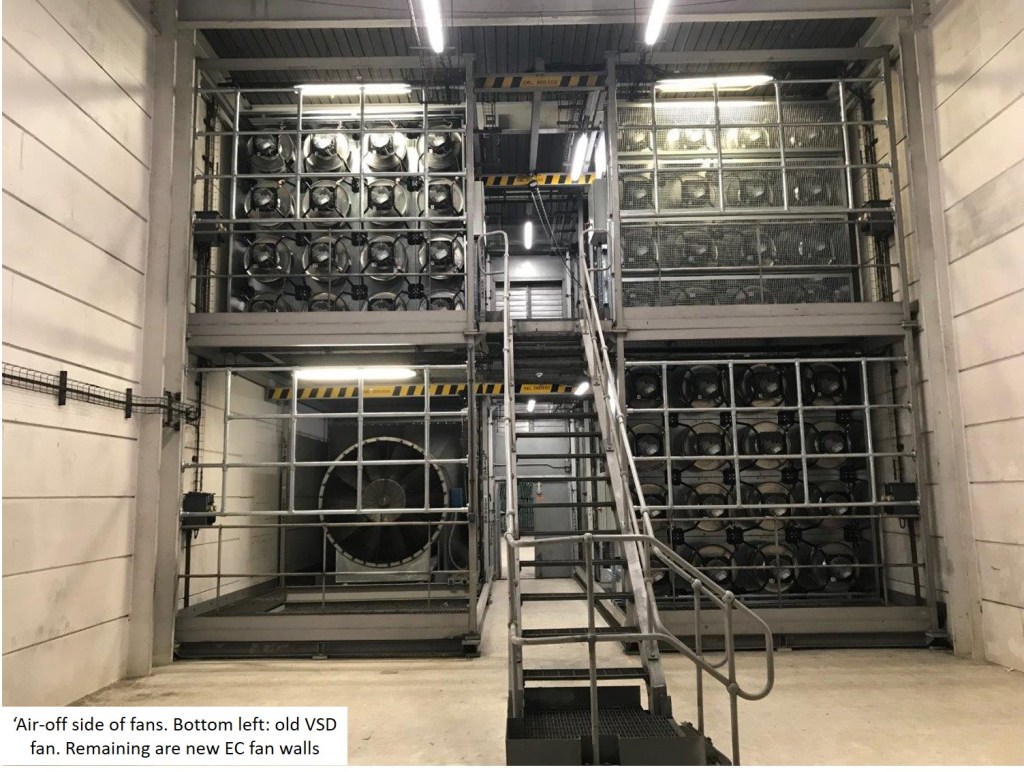

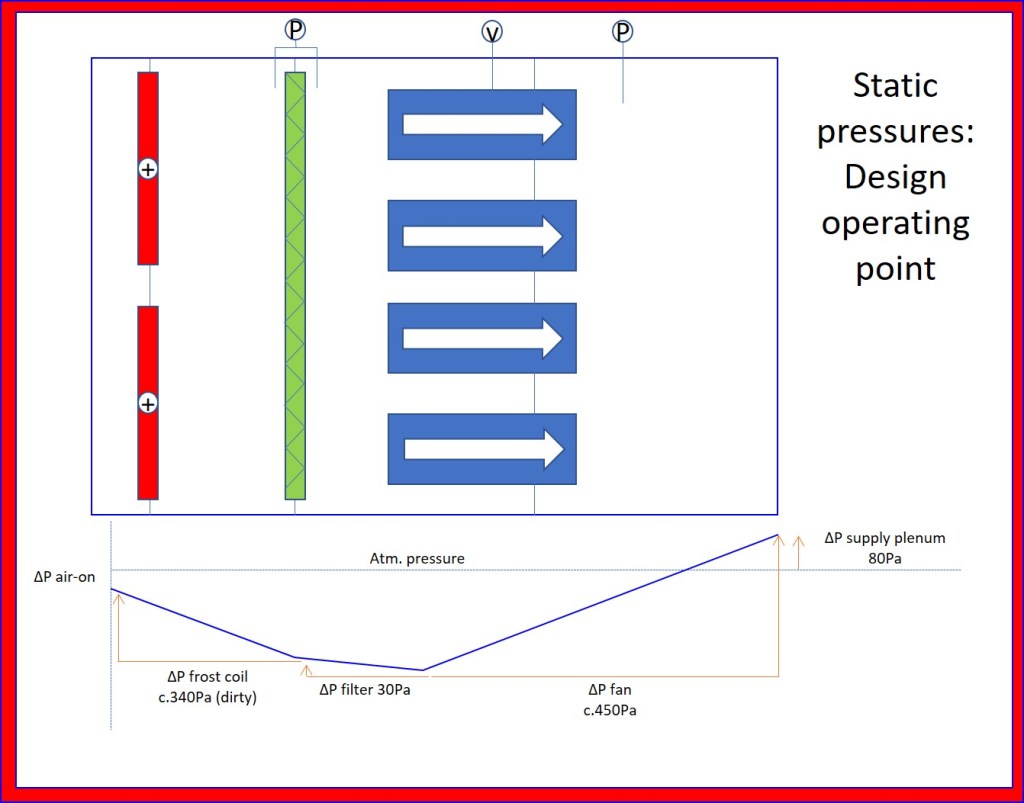

Part of the portfolio I have responsibility over as PM is the replacement of variable speed drive (VSD) motors with the retrofitting of electronically commutated (EC) fan-motor units (energy efficient motors, DC brushless motors by another name, sorry for the simplification John Marsh!). One of the sub projects is the removal of the original VSD fans from the three primary fresh air tunnels which provide fresh air to Terminal 5A. Essentially, there are three tunnels each with design flow rates of between 180 and 240 m3/s and a downstream plenum pressure set point of 80 Pa. These design conditions allow the AHUs within the terminal building to be able to ‘suck’ (I know pumps only ever push, Mark Hill!) fresh air into occupied spaces within the building. Each of the old VSD fans was replaced with a fan-wall composed of multiple EC fans.

The project was completed in late 2019 and the static pressure in the plenum has never consistently reached the 80 Pa set point. There has been multiple inspections and heated conversations over who is to blame.

On the client side, Heathrow are clearly disgruntled at the increased energy demand of the fans, currently running at 100% (with no redundancy) and not meeting operating conditions. The operational engineering team within the terminal believe it to be a lack of capacity from the newly installed EC fans.

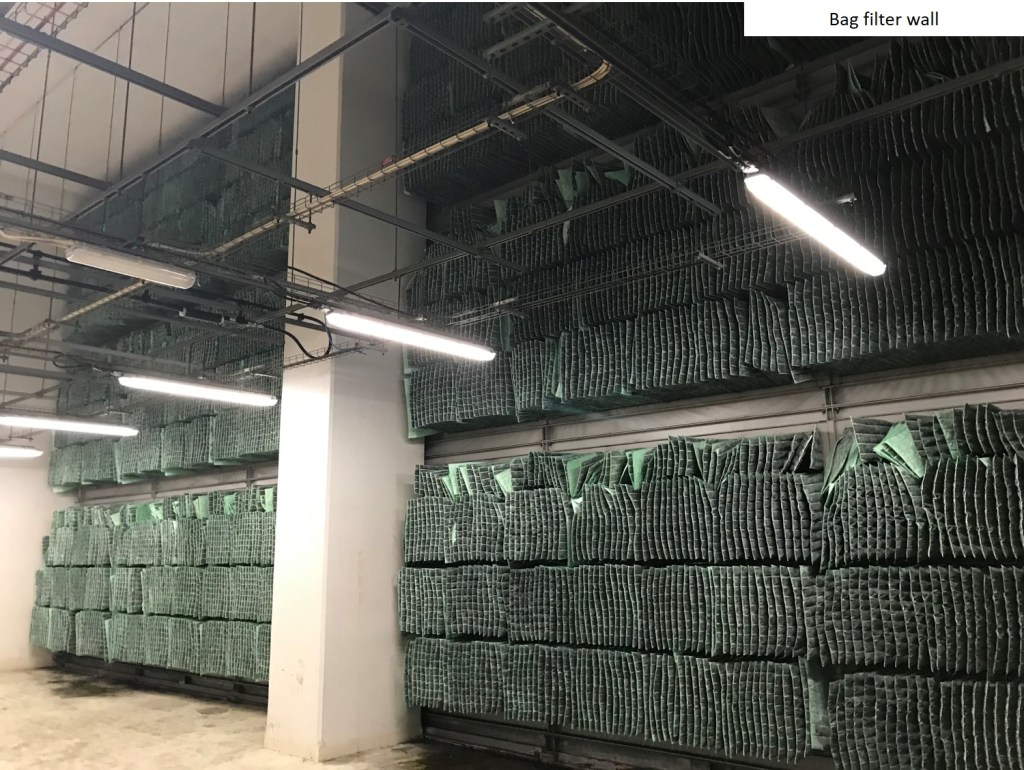

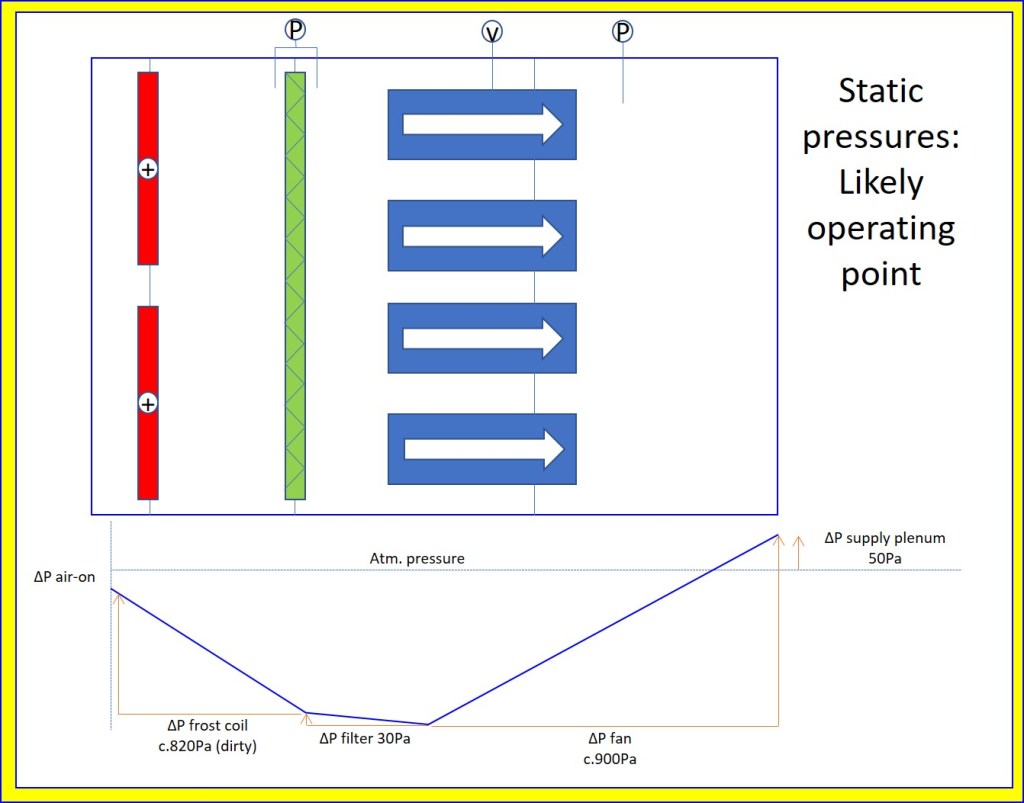

On the contractor side, they believe the fans are being ‘choked’ through poor cleaning and maintenance of the frost coil and bag filters that are the in the system and that the design is as specified by the original project scope.

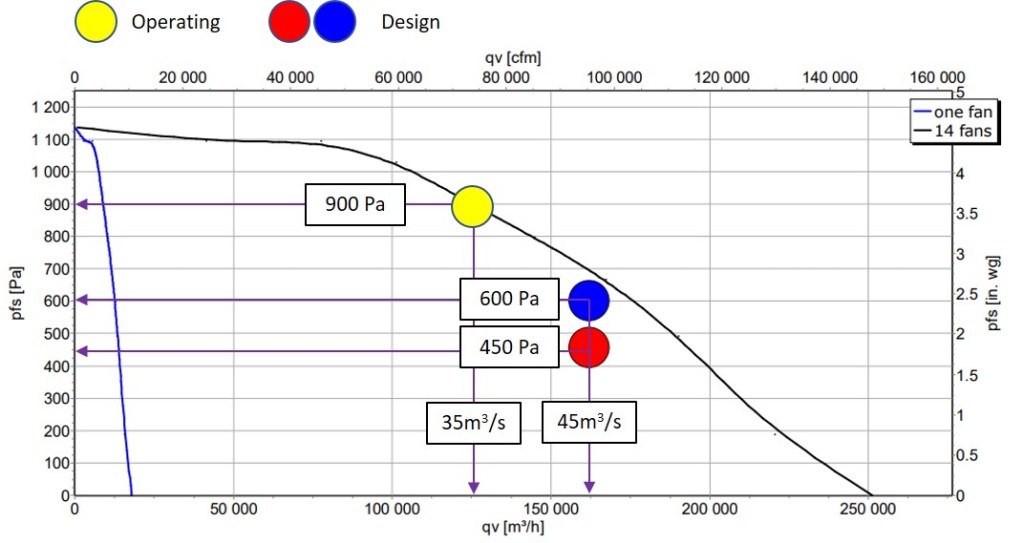

There had been a plan to install more pressure and temperature sensors within the tunnel but at this time there is no way to measure differential pressure across the frost coil or fans. The manufacturer of the EC fans published the fan-curve data as in the figure with the two operating points based on the original project scope that was handed to them in early 2019. Original commissioning information puts the maximum allowable differential pressure across the frost coil as 50 Pa and the bag filters at 225Pa. The frost coils are currently extremely dirty and gummed with incoming material entrained in fresh air. Although DP across the frost coils cannot be directly determined the bag filters are not running at anywhere near this upper limit.

The figures below show the likely operating conditions as is, along with the two cases published by the manufacturer, IF the EC fans are performing as per the published fan-curve.

Research into original commissioning information has revealed that there is a large difference between the maximum available duty of the VSD fans removed and the smaller EC fans retrofitted. Although this extra duty is not required in ‘normal’ operating conditions (ie. if the filters and coils remain clean and with low enough DP) in the past it could have easily allowed to overcome poor cleaning and maintenance of components by simply ‘turning it up to 11’.

Following some investigation I think there to be are a number of possible outcomes, in order of likelihood, following the correct cleaning of the frost coils an replacement of bag filters:

- The system will operate correctly and pressure set point is reached. Everybody goes home happy and electricity bills reduce.

- There still lacks the sufficient pressure in the fresh air plenum. This will then cast doubt upon the EC fan capacity and likely reveal that the original scope handed to the manufacturer did not allow for the total air flow capacity of the original VSD fans; no fault of the designer. Due to the size of the project this will likely be tolerated and downstream operation strategy of AHUs will have to change from working on pressure set points to perhaps CO2 levels.

- The EC fans are found to be lacking still and only through extra monitoring of running conditions of the fans (differential pressures and air volumes) the manufacturer is held to account.

Hi Al, very interesting read. The one thing that I’d like clarification on if possible is detail regarding the advantages of EC motors over VSDs (I take it they were variable frequency drives?). I’ve just had a quick google but it isn’t immediately obvious why EC motors outperform VSDs, am I right in thinking both of the motors principally save energy by being able to adjust their speed? Is it the fact that the residual/base losses of the EC motor are lower than VSDs/VFDs that make them so desirable?

Very interesting stuff Al. It seems to me that this is a classic case of assumption being the mother of all fuck ups, with the fatal assumption (as in understand it) in this instance being that the VSD motors were operating at design conditions and this duty was sufficient for the load, when in reality, the fouling within the ductwork necessitated pushing the VSD motors beyond their design intent (cranking up to 11). This implies to my mind that the original VSD motors were maybe oversized in the first instance and this oversizing had been masking the issues with system fouling?

If you had the opportunity to go back in time and be part of the team who identified the engineering problem and susbsequently crafted the SoR for the contractor, what would you have done differently?

John, the new EC fans were originally pitched as an energy (and cost) saving opportunity for the two main reasons of:

-electrical power usage: at all air flow rates the newer EC fans use less electrical power and so make a cost saving in this way. If we think back to Marshy’s lectures (DC brushless motors). the EC fans change speed/torque by providing a changing excitation current to the spinning fan axle, which changes the electromotive force etc etc.

-maintenance: the EC fans are marketed as ‘maintenance free’. What this actually means is tht they comes with a 12 year run life without any requirement to change/maintain any components. When you consider the alternative is a variable frequency drive with a belted motor to a fan in the air stream, can be seen how this ‘dirtier’ set-up will require more maintenance.

Scott, you’ve assume completely correctly. The original fans, rated at up to 90kW electrical, had enough push to overcome some dirty system components. If i were back in 2008 and responsible for commissioning? I would have installed more comefri sensors to be able to accurately tell when stuff needs cleaning and the operating conditions of the fans.

In a nutshell then (Correct me if I’ve misunderstood):

An EC motor with an adjustable excitation current for speed control is more efficient than an inverter altering the frequency of the supply for speed control?

I imagine it can get quite technical when digging into that?

Maintenance point makes perfect sense!

Essentially yep. The fan/motor combo needs to be looked at in combination with the whole circuit’s resistance (system curves and all that), in order to determine/predict how the retrofit will be beneficial. In essence it’s down to specific fan power (SFP) which is the electrical energy used for every volume of air pushed, units kWh/m3/s, simplifies to kPa in SI (there you go Harry!). At almost all air flow rates the SFP for the EC motor set-up is preferential to a VSD motor and belt. However(!), some of the common practice I have seen is heavily based on assumptions and the proof of energy saving is not always carried out but assumed for an EC motor retrofit job, for reasons including; lack of BMS sensor data, lack of proper scrutiny and time, comfort with the assumption that a trial retrofit scenario applies to other cases in a similar manner (clearly not to be the case given each ductwork system will almost certainly be different and the operating points of each AHU will be unique).

^^ correction! SFP is kW/m3/s. i clearly need some Ph1 tuition again.