Assessing Plant Loading on Concrete Slabs

For the last couple of weeks I’ve been working for a Client (Keltbray) who was awarded the work to re-purpose a 7-storey office building at St. Pauls, London. As part of the structure re-purpose, Keltbray are required to conduct a full soft-strip and a partial demolition of certain structural slabs, beams and walls.

One of the design briefs issued to me was to confirm that the structural slabs on each floor had the capacity to support various plant including a Bobcat T450 compact track loader (see below). The T450 has an operating weight of 2,961kg, a track length of 1.28m and a track width of 0.3m.

In this post i’m going to summarise some of the quirks associated with plant loading and their load cases, and summarise some of the different methods I used to assess an in-situ slab.

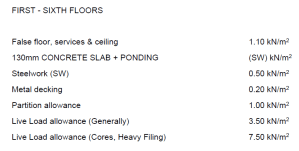

Check 1 – Structure Design Loads

Fortunately the Client was able to provide me with a demolition specification document which defined the working loads for which the structure was designed originally. If these are available, of course the simplest check to do is to see if the pressure exerted by the plant is less than the allowable loads as specified in the design load. In this instance I knew that after the soft-strip all false floors, services, ceilings, partitions and any other variable and quasi-permanent loads would have been removed. This consequently left me with 5.6kN/m2 slab capacity, unfortunately a very crude calculation showed that the load exerted by the plant would result in a pressure of nearly 40kN/m2.

Note – When using this method there is no requirement to factor the plant loads.

Check 2 – Check Max Bending and Shear

If check 1 fails, as it did for me, the next consideration should be that whilst the plant exerts a much greater pressure than the design loads, it is only exerted over a small area, compared to the design loading which could be exerted over the whole slab span. To do this I needed to consider the various loading combinations of the plant.

Step 1 – Establish loading configurations of plant

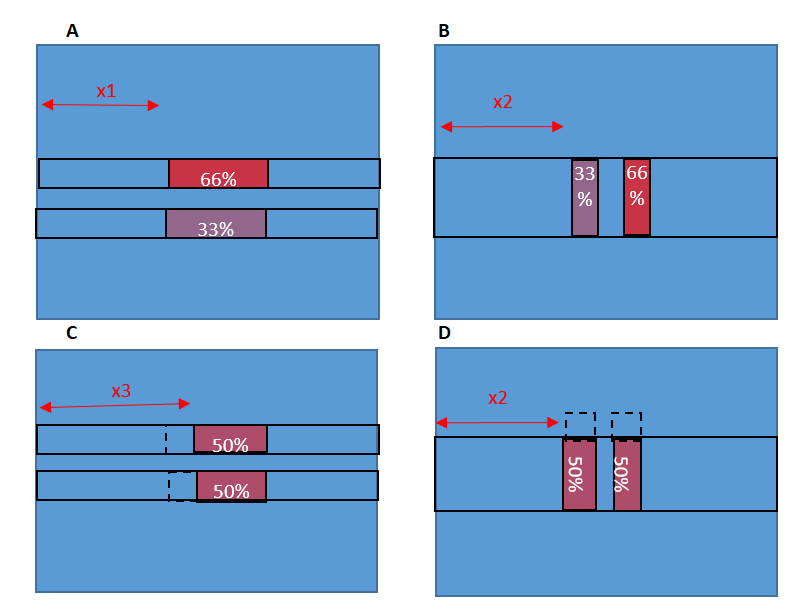

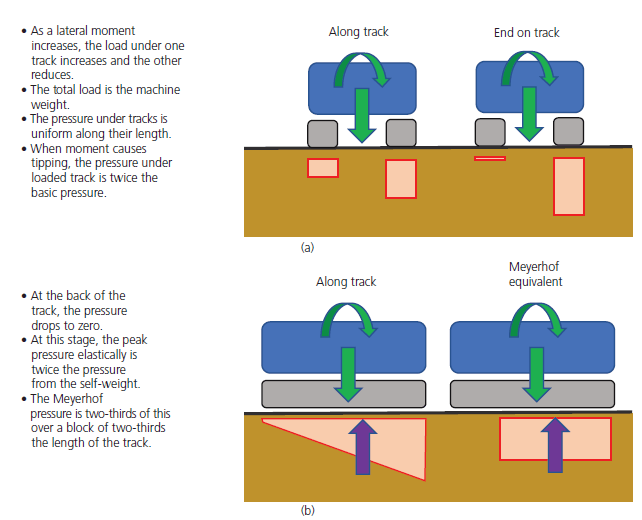

Tim Lohmann, Director at WHP, wrote an article in the ICE Forensic Engineering Journal explaining that the moments experienced by plant (through their typical construction activity) can cause an imbalance of loading. When these moments are perpendicular to the direction of the tracks, it can lead to up to 66% of the load being transferred through a single track. When the moments are in the same axis as the track direction, they can lead to a 33% reduction of effective track bearing area to due to the Meyerhof principles.

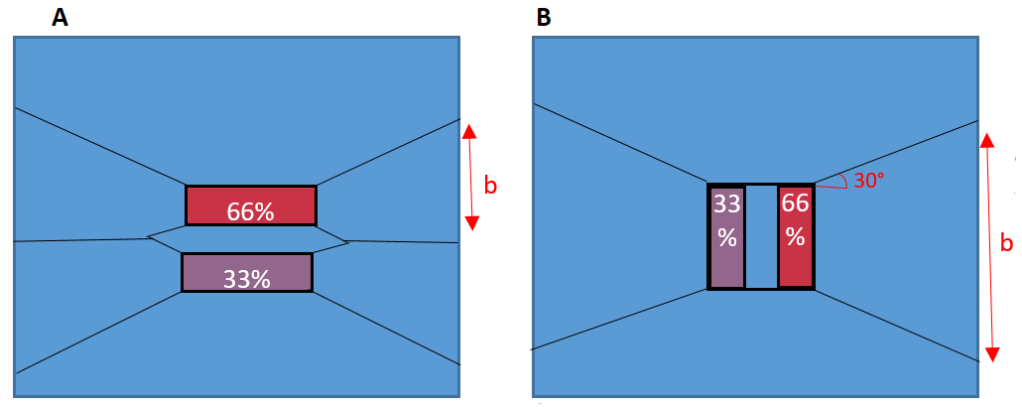

These principles are demonstrated in the figure below, for more information the article can be read by clicking ‘download’ below.

Because the slab I was assessing was one-way spanning, I had to consider both cases (a) and (b) above for the plant sat parallel and perpendicular to the slab direction. The four cases considered are in the diagram below. To find the max bending moment, the plant has been modelled at the mid span of the slab.

Step 2 – Calculate max SF and BM due to plant loading

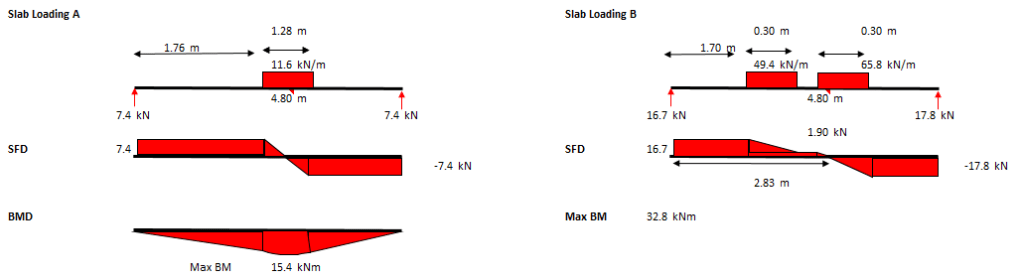

The maximum bending moment and shear should then be calculated for each of the 4 combinations shown above. The SFD and BMD for cases (A) and (B) above are below.

Note – Ensure that the span you select is the maximum slab span anywhere on the floor you are assessing, as this is where the maximum BM will develop.

Note – The loading due to the plant should still not be factored.

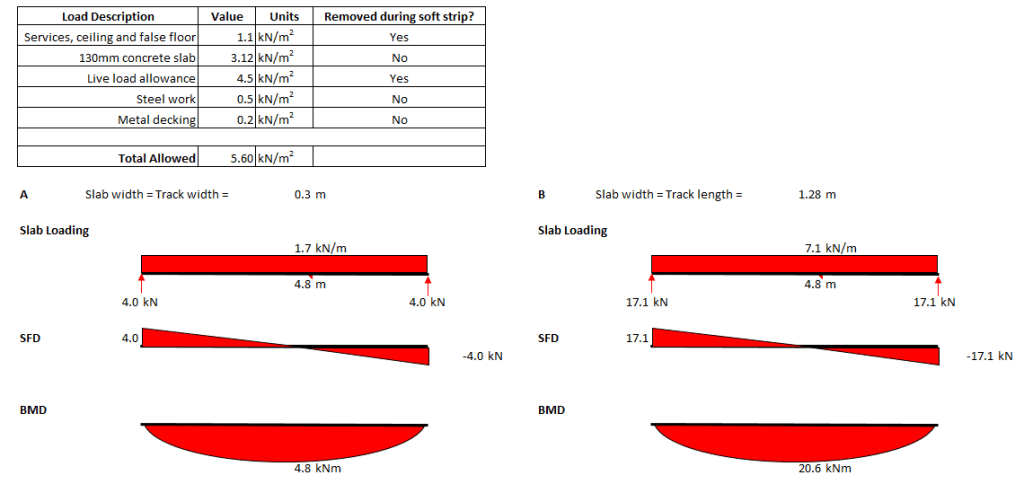

Step 3 – Calculate Max SF and BM due to slab design loading

Using the design loads for the slab (5.6kN/m2 as determined from demo spec), the maximum SF and BM that the slab has been designed to withstand can be calculated. Below are the max SF and BM for cases (A) and (B) above. The 5.6kN/m2 pressure has been multiplied by the width of the one-way spanning slab being assessed which is a track width for case (A) and a track length for case (B).

When compared to the max BM due to the plant in step 2, you can see that the SF or BM due to the design loads is significantly less than the SF and BM developed by the plant loading. If, when checked, it is found that these BM and SF are greater than those developed due to the plant, the assessor could safely say that the slab does have capacity for the plant.

Check 3 – Slab Section Analysis

If check 2 failed then the checker should check the section properties of the slab for capacity against the max SF and BM developed in the slab due to the combination of plant loading, slab self-weight and any other loads that may not be removed during the soft strip. Whilst the plant is positioned at the mid-span, the max BM will be at the mid-span.

Note – For this check the loads should be factored.

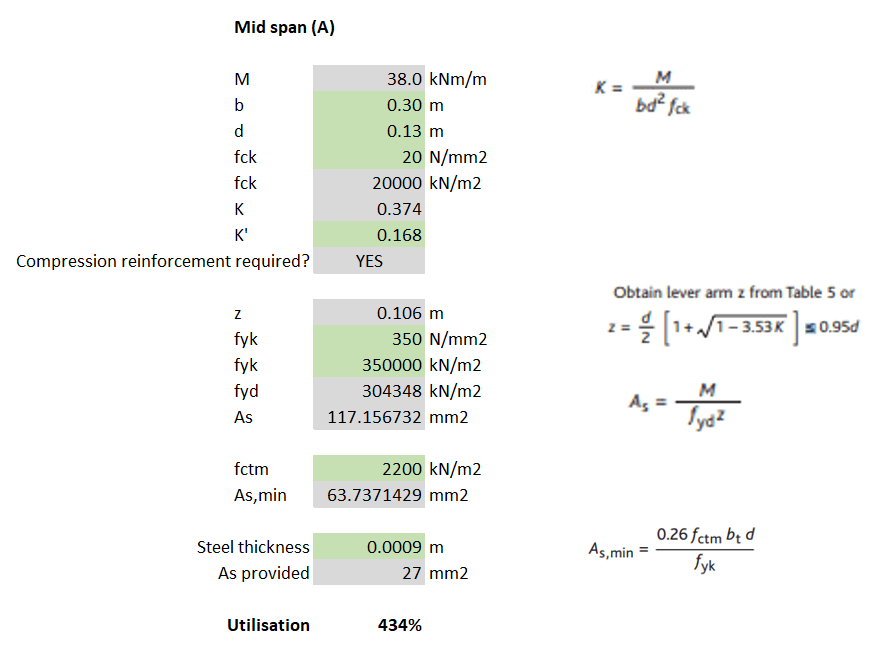

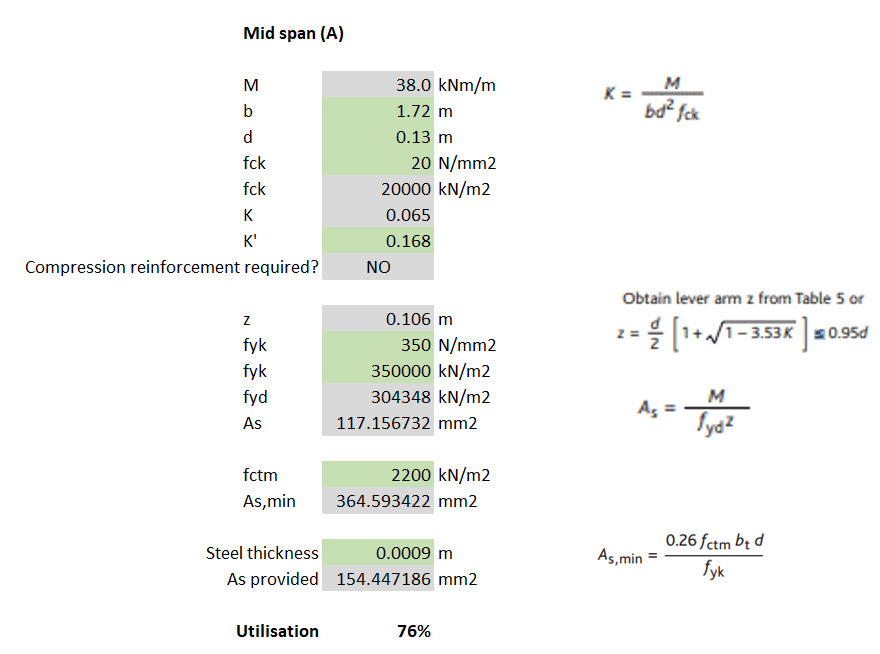

For my example, I calculated that for loading case (A) the max BM was 38kNm and then used EC2 to determine the steel reinforcement required. Because the slabs I was analysing were 130mm deep composite (steel deck) slabs, the 0.9mm thickness of the steel deck can be assumed to work as the tensile reinforcement.

Note – The yield stress of steel deck is unlikely to be the same as that for structural rebar (500N/mm2). I found it ranged between 280-350N/mm2 but check the manufacturer’s technical literature. The assessor should also check that the steel deck allows for sufficient bonding with the concrete for it to act compositely (normally achieved with dimples in the steel and shear studs).

A fundamental part of the check requires the slab (section) width to be considered. I noticed that when I considered load cases (A) and (C), where the slab width = track width = 0.3m, the section did not have sufficient bending resistance (failed by 334%) – see calculations below.

Check 4 – Assume load dissipates at 30 degrees

The assumption I had made from the very beginning was that, because the slab was one-way spanning, it was only the width of slab that was being loaded that could provide any resistance to bending/shear. However, according to BS8110-1, similarly to the way a concrete beam without shear links will normally fail on a plane inclined at an angle of about 30° to the horizontal, it can also be assumed that even a one-way spanning slab will utilise the strength of the surrounding slab, at an angle of 30 degrees.

Using the principle described above, a new b (slab width) can be determined which can be inputted into the same section analysis conducted in Check 3. For load case (A), I calculated that at the slab support, the slab width was now 1.72m. This new slab width allowed me to calculate that the slab did have sufficient tensile steel.

Note – The issue with utilising this 30 degree spread is that the same checks should be conducted with the plant moved from mid-span to close to the supports. As the plant is placed closer to the support, the max BM will reduce but so will the effective width of the slab (due to the 30 degree spread).

Additional checks required

- Whilst max bending occurs whilst the plant is at the mid-span, max SF occurs when the plant is closest to the slab support, this should be modelled to check shear capacity and punching shear.

- If check 4 (the 30 degree spread) is conducted, checks should be conducted for all 4 load combinations with both the plant at mid-span and close to the supports.

- If the slab is continuous, checks for tensile reinforcement in the top of the slab to deal with hogging should also be conducted.

Summary

When working for a design consultancy, the efficiency with which we carry out these kind of checks is what makes the company the most money. This post demonstrates a hierarchy of checks that can be used, from most basic to more complex until I reached the stage where my check passed. Whilst the labour intensive check 4 gives the highest chance of a check passing, a quick check might show that the simpler checks 1 or 2 might also pass (and take a fraction of the time to complete).

If even check 4 fails then FE analysis may be required. Otherwise it might be time to tell the contractor that they either need to downsize their plant, or back-prop their slabs.

Jordan a really interesting read. Thanks for posting. I’ve not been involved in this type of analysis before so a couple of questions if I may:

1) Do you account for the machine bucket being full in the machine weight? Is this what Wc is referring to in Tim’s article where W = Wm + Wc?

2) You say theres no requirement to factor the plant loads in Check 1 and 2. Is there a code basis for this or just approved practice? I might have misunderstood or missed something.

3) I was interested to see you considered both parallel and perpendicular moments for the skid steer. I can understand why both would be required for an excavator but I’m struggling to see what would cause the skid steer perpendicular moment unless it was being operated over uneven debris which could cause it to tip over sideways. Again have I missed something here?

Hi Mark, thanks for your questions. Sorry that I didn’t clarify these in the post, it was longer than I’d expected already!

1) In Tim’s article he says that Wc = the crowding force from excavator working. Whilst i’m not exactly sure what this means, yes the load from the bucket load should be included. I only considered the vertical load of the bucket load. It will of course induce a moment but the moments have already been considered for in the different load cases considered.

2) My understanding is that when conducting the type of analysis explained in Check 2 (Step 3), the slab capacity (5.6kN/m2 in this case) is given as a working load. That is, when the designer originally designed the structure, they would have factored their loads, the output of which would have been a safe working load. Typically loading capacities given to on-site teams are working loads so there is no requirement for the contractor to factor loads by any partial factors, reducing the risk of error. Another example of this is that most proprietary equipment gives the capacities of their props as working loads. You could consider Check 2 to be a type of back-analysis. However, if check 2 fails and check 3 is used, primary analysis is being conducted and the loads must then be factored.

3) This is something I didn’t elaborate on for brevity but you’re absolutely right. When I conducted my checks for the track loader I used judgement to determine that there would be no moments induced that could tip the Bobcat sidewards. However as you say, an excavator with an arm that can slew could induce these moments. Tracking over debris is a case where a sidewards moment could be induced even for a track loader but as part of my calculations I made the caveat that plant was not to track over heaped demolition debris for this very reason.

Jordan thanks for the response and clarifications. I’ve certainly learned something new through your post- thanks!