Grasscrete – Paving the way to a sustainable future?

Recently, whilst working on a small access road I was introduced to what I thought was a novel, sustainable and simple paving solution – Grasscrete. After a cursory Google search, it transpires that it has been in existence since the 1970s- and indeed some of these uses are still standing. So what is it? And has anyone come across this before?

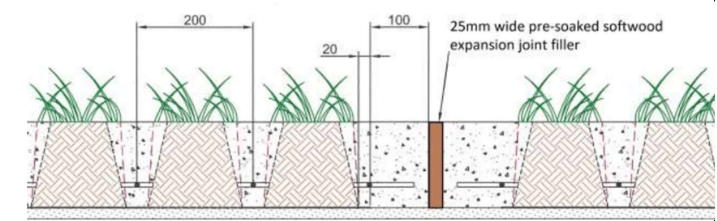

Simply put, it is a permeable pavement made up of recycled plastic formers and some steel mesh. Once installed some configurations claim to be able to carry weights of ~40T and use approximately 50% less concrete, with no need for active drainage. Relatively simple to assemble one can see why it would be attractive to a customer such as the MoD:

Less concrete means less water, less cement and ultimately less logistics – usually a major consideration when operating in austere environments.

Resistant to differential settlement – Acting as a monolithic slab, loads are uniformly distributed.

With much less run-off, grasscrete is more resistant to storms and stormwater run-off, not requiring active drainage.

Much more durable for expedient roadways and even HLSs for expeditionary theatre entry.

So what are the downsides?

More expensive than standard RC slabs

Plastic formers can be fragile – especially if left in hot temperatures or direct sun.

Lateral forces, especially from heavier vehicles braking/accelerating, may crush the narrower sections of the voids.

Rebar is at more risk from corrosion, minimum cover – especially if voids are filled with soil rather than quick draining gravel.

Whilst it may seem that I’m taking a commission from Grasscrete (c), perhaps Grasscrete/permeable pavements are something the Corps could look at? Whilst not structural and worth a TMR or two on its feasibility, I thought I’d sow the seed on this one…

I’d be keen to see if anyone else out there has seen this before and perhaps why its not been rolled out more often, especially for less trafficked areas/access roads etc. Without getting too far into the weeds…

What’s the total construction time for a set chainage (say 100m)? If you only have to dig down a little (or maybe just strip topsoil if you have a decent subgrade) would be interesting to compare timelines and plant requirements to say, the PAM figures for a similar unbound earth road.

There’s a few factors that’ll affect this – taking into account workforce, ground conditions, concreting kit available etc. As a planning figure the section in the photo (~50m x 3.6m) took about 3 weeks, however the ground was incredibly saturated and this is with 700mm sub-base + capping (designer’s choice, not mine!). On that basis I would venture that 100m (in optimum conditions) could be achieved in 2 weeks? Plus some curing time for full load bearing.

Not much of an answer I’m afraid!

out of interest what type of loading can this take? / what has it been designed to be trafficked by? – I’m thinking WRT RE application could we traffic it with our B and C vehicles? I’m thinking probably yes?

Depends on the mould sizes. Tracks would rip these apart so as you say B & C vehicles only. Depending on the size of formwork and what size steel mesh goes in – up to a vehicle load of 40T according to the manufacturer, specified as an allowable point load of 41kN (over a 150 x 150mm piece). Although you’d have to make sure you had a pretty solid sub-base with a ground bearing capacity >44kN/m^2

So in summary – yes, it could take some B and C vehs.

Sorry for late entry on this…. Grasscrete has indeed been around for a while, at the beginning of the millennia I used it for fire routes around sheltered accommodation and gym/sports facilities which would not normally be trafficked save perhaps by a mobile access platform conducting facade repair work or similar. The original version was supplied as 600×600 precast pavers for laying by hand on a prepared base course or directly onto a prepared subgrade. Normal form was not to be unduly worried about water in the pavement layers because it was not being routinely loaded and unloaded. There were three issues we encountered fairly regularly; uneven settlement of the ground around the perimeter of new buildings where the foundation for the track was not prepared subgrade or engineered fill i.e. dodgy “it’ll be reet” builders attitude to “a bit of paving” which lead to uneven pavers with edges standing proud or cocked at an angle. clearly not an issue with in situ mesh slabs like the newer version will provide. The second issue was drainage of the track because a prepared base does not let water through as quickly as a storm deposits it. so a track that doesn’t fall away to the side can become a stream bed very quickly. The solution was to treat it as an impermeable surface and try to shed water to a point of disposal without need for formal drainage. The final challenge we found was that the alkali nature of concrete and poor quality of backfill usually meant that grass struggles to establish and more often than not all than you had after about a year was a concrete grid of encased mud that had usually shrunk below surface level and was a risk to anyone walking on it due to the uneven surface, potential to turn an ankle or trip. The Corps did use it quite extensively in the 39-45 period and there are still examples of it around although most have now been replaced with more suitable surfaces. Perhaps the time has come for the technology to be properly revisited?