Archive

Defects in Melbourne Fitout

I am currently working in the “tenancy team” at Norman Disney and Young in Perth CBD. The tenancy team completes small scale building services consultancy fit out projects in a short period of time – usually a couple of weeks from start to finish.

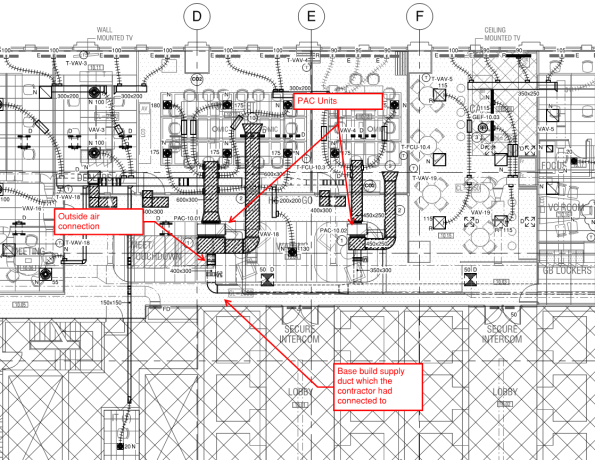

Amongst several other small projects, I have been given responsibility to consult on the mechanical construction phase of a HSBC tenancy in Collins Street, Melbourne. During the commissioning phase, a colleague of mine in Melbourne compiled a defect list, which happened to be extensive and include a number of concerning items. Given the tight timelines, by the time I received this document, users had moved in and started operating in a functional office space. One defect in particular was alarming – the mechanical contractor had connected outside air provision for two packaged air conditioning (PAC) units to the existing base-build supply ductwork. This presented a series of problems:

- Insufficient outside air provision to the two main meeting rooms.

- Imbalance of the existing base build system.

- Conditioned air being introduced to return air in the PAC mixing boxes.

To make matters worse, the client has unsurprisingly received complaints from the users – half complain about being too hot, while to rest are grumbling of being too cold. As the proverbial rolled down hill in my direction, I was asked as the mechanical design authority to rectify the situation. Both the builder and mechanical contractor were naturally eager to shift responsibility to the mechanical design, when in fact the system had been installed incorrectly. After an afternoon of rather animated phone calls and meetings, the mech contractor is now starring down the barrel at removing office users, taking ceilings down and installing the ductwork correctly. And rightly so! Understandably, both the builder and contractor were set on blaming the consultants design and I had the pleasure of going through the system design calculations with both parties. Luckily NDY’s design and quality assurance for this particular project was thorough and correct.

See Mark up attached.

I am somewhat surprised that the builder/ project management company allowed the user to move in before all of the defects had been addressed. Additionally, the original commissioning results are incorrect, invalid and wrong. To that end, I am pushing my project leader to request a re-test by the mech contractor – with a perhaps a young, enthusiastic, British engineer in attendance 😉

Update – Picture for you Fran.

xx

‘Expectations for those heading to Australia to work for Multiplex’

1. Multiplex have an excellent reputation in Australia for being a ‘fair’, reputable builder. They aim to employ good people, pay well but expect a lot!

2. It is highly likely that middle management will expect 12 hours + per day. Get stuck in, but set your stall out from the start. My priorities were academic work, gaining varied site practice and experiencing Australia – not working all hours to get my line manager promoted.

3. They push the contractors hard. Some bully, some build relationships, which was interesting to observe.

4. They work in fast paced environment. I found processes, general administration and management of pers to be lacking in comparison to what I’m used to. They were clearly focused on building stuff on time and making money $$$$ !

5. What we consider as unethical practice happens every day on site! (in WA anyway)

6. Attitudes towards health and safety can be extremely varied. Be mindful of the term “that’s a Saturday job”.

7. Workers unions are very strong and powerful in Australia. The majority of Multiplex projects are union sites which present their own management battles.

Give me a bell if you want to discuss anything further: +61 498 145 474

Great Idea

I saw this in an email from a director while working in a design consultancy and thought what a great idea to generate work. Suggest something similar within the organizations you work for and claim it as your own idea….even earn yourself an Omega watch?

NDY Perth recently offered to update the engineering standards for the University of Western Australia (UWA) – I assume this was done at no or very little cost? This provided the university (a huge organization with enormous amounts of real estate) with up to date building/maintenance codes for which any contractor working on their site must conform to – it forms part of the initiating contract between the university and any third party contractor. In return, NDY reap the rewards of consulting on any large future projects the university carries out. Assuming UWA appoints them!! Great business methods and one in which could be applied to any large organization that maintains real estate.

Unrelated and just for fun: A friend and I were playing around with a time lapse camera this Christmas – he produced this. Pretty cool…?

Steel Penetrations

The New Perth Stadium faces a race to be ready for the first Australian test match of next summer – which also happens to be an Ashes year. I’m hoping I’ve contributed enough to badger a couple of hospitality tickets for the first day for some good old fashioned international relations engagement.

Throughout Phase 2 I have managed the entire services steel penetrations register and works. This involved receiving penetration requests from sub-contractors’ BIM modellers, confirming all alternative solutions have been exhausted, gaining structure approval and instructing a cutting firm to carry out the works. In the 7 months I have spent on site, over 200 penetrations have been cut in the structural steel. As the majority of these works have been completed on ‘day rates’ Multiplex is now feeling the cost of hurried structural design, which was forced through without considering the full extent of services within a stadium.

After a conversation with the Senior Services Manager, he claimed every effort was made to delay the steel frame construction so that most (if not all) service penetrations could be captured. Instead, the button was pressed acknowledging future penetrations would be required. Although not privy to exact costs, I assume the price of cutting hundreds of penetrations (and installing stiffeners) in structural steel far outweighs the cost of delaying steel fabrication over two years ago. Something for us all to consider in the future..?

Just for a bit of fun:

…?

…?

Plinths for MSBs

Not the most exciting blog from me, but any assistance would be appreciated. Has anyone dealt with plinths for mechanical switch boards (MSB)? They are all being installed in ground level plant rooms of a sports stadium – some of which house AHUs and significant ‘wet’ pipework. Having dug into the specifications, there appears to be no requirement…?

That said, I presume it would good engineering practice to install a concrete plinth to aid installation, routine maintenance and prevent damage.

Cracking photo worth sharing…

Busy sports afternoon. Standing by for deserved abusive responses….

State to check major projects after deadly asbestos found at $1.2b children’s hospital

Hot off the press:

“Two major State Government projects will be checked for asbestos contamination after deadly fibres were found in roofing panels of the new $1.2b children’s hospital.

The State Government announced the audit this morning after Health Minister John Day said tests had confirmed the asbestos.

The roof of the hospital will be replaced and could further delay its opening.

Premier Colin Barnett said the latest problem with construction of the hospital meant builder John Holland would struggle to win other Government contracts.

The contaminated panels were supplied to John Holland by a company called Yuanda.”

Yuanda (Chinese subcontractor) are supplying the façade at the New Perth Stadium, as a result we have had state government health inspectors on site all day.

Some of the newspapers are suggesting JH are sourcing ever more Chinese products since their take over last year.

All Fran’s fault….!

One for the Cs.

Since arriving at the ‘New Perth Stadium’ I have spent the majority of my time on site – predominately to top up my ever improving glowing tan, but also coordinate an entire services install on a $1.4 Billion 60,000 all seater stadium. Last week, while stood in the middle of a disagreement (read massive punch up) between the blockwork and plumbing foremen, I noticed our mechanical air side contractor had started hanging fans and attenuators. See picture below.

This led me to ask a few questions – how heavy are these items? How are they hung? Were there any constraints? Weight limits? I also remember how poor concrete can perform in tension so thought I’d better act on my initial concerns and investigate further.

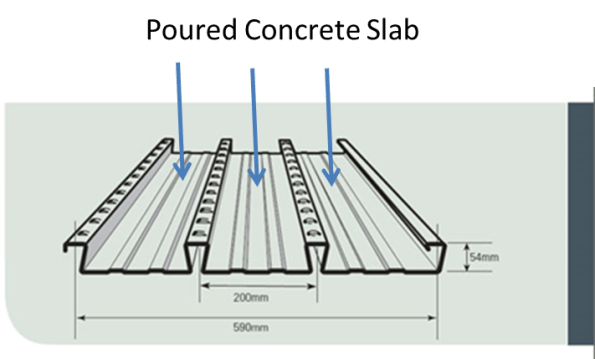

The current slab detail is simply made up of Bondek and poured concrete as detailed below:

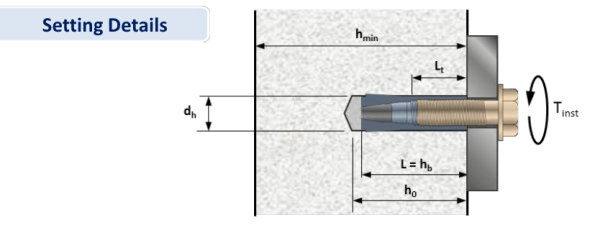

SOP for hanging fans involves drilling a 50mm hole through the Bondek and poured slab, before driving in a M10 drop in anchor which simply splits open at the top to provide a means of attaching a hanging rod.

So simple, even the E&M arm wrestling champion understands….Safe working load in tension for each item are published as:

Drop in Anchor – 3.4kN

Hanging rod – 10kN

Therefore if a fan is hung as per the photo with four anchor points, one could assume a weight limit of 1360kg. [(3400/10)*4]. Luckily (or unluckily) the Icelandic Arup Structure Consultant sits next to me, so I thought it prudent to confirm my findings before giving the green light to install 60 enormous fans.

His response didn’t fill me with confidence “go ahead and install the fans/attenuators which weigh between 200-300kg, heavier items may require secondary steel.” I AM YET TO GET THIS IN WRITING! This left me with further questions and additional concerns – not least how long is this steel going to take to design, how long before it is installed and who is going to pay for it? Services install is months behind schedule and I fear this issue is only going to compound our woes! What is more concerning is that I have no doubt that our mech air side contractor is ignoring all advice and hanging everything as fast as they can in order to knock off at 1430hrs. Welcome to WA. Best get back on site…..

Beer Economy

Has anyone else experienced the ‘beer economy’? Credit for anyone who knows the going rate for removing the three and a half blocks detailed in the picture below. It would personally take me 4 minutes with a Stihl Saw.