Archive

Is there such a thing as half a pour?

More rain again this week, but surprisingly Centre block decided to push ahead with a 620m3 pour that both started and finished in the rain. At some points it was torrential; the concreters walked off the slab several times and it was hit or miss whether they would have to place an emergency construction joint. The decision was taken to push through as the slab was not being poured to a finished surface. The pour took 13 hours to complete!

Concrete Finishes (South Block Golfball effect / Centre Block after the pour(ing rain) / the drip marks from overhanging formwork)

The following day was not quite as wet, but a very wet start caused the concreters to walk off site swiftly followed by all the other trades. This was supposed to be pour day for my SB GR Z2 slab but as nothing was completed the day before it was put off till Sat. I went on a site walk with the South engineers to just generally have a poke around at what was going on in the North and Centre. It was also a good opportunity to see techniques that will be incorporated into the South build shortly.

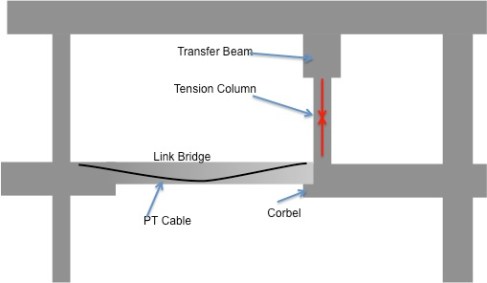

I had only heard of a tension column once before, not sure where though. It is pretty simple in concept really, the column hangs from a substantial transfer beam above, which sits on 2 hefty columns. The column will hold up a link bridge between the East and West blocks. The bridge itself, though only about 20m span has 4 longitudinal double PT beams which appeared to be overkill but when looking at the other end of the beams they extend 2m into a large transfer beam which must take a larger proportion of the bridge load to leave the tension column with less. I do question why it is a concrete column as a cable could probably do the same job more efficiently, but assume that architecturally it must fit with the aesthetic of the building.

My real issue this week is that of the topping layers. I have written briefly about the integrally poured topping layers before and I think I expressed my concern about pouring an additional 150mm on top of a structural slab with the initial pour. Essentially this is a money and time saving exercise (Concrete is cheaper than a screed layer poured at a later date) at the expense of quality (finish). The standard of concrete slab poured on the project so far has been pretty poor in my opinion (undulations mainly), so to increase the depth of concrete slab poured to over 500mm increases the potential for undulations. This was found on the pour of SBGRZ6 recently (The deck rings/snakes worked by the way though the steel fixers thought that they were too much work), where there is not fairly deep undulations in the surface of upto approximately 20mm – well over the tolerance allowed in the Aussie Standard.

The second issue is that immediately pouring to the FFL leaves no room for making good. What is poured is what you get. To pour a screed layer later is not only be expensive but time consuming but it does give the opportunity to produce a finish that will be accepted by not only the client, but the follow on trades. In some cases in the South after a light shower after the end of the pour the entire surface became pocked, similar to a golfball. This is not acceptable for the waterproofing trades so remedial action is required to grind down the surface to a smooth steel trowel finish which will not only cost additional cash it will be difficult to attribute to the concrete subcontractor as they had finished the job, but contractually they are responsible for the concrete finish. Difficult. From a JHG perspective it’s their problem, but from my firmly set moral compass I find it difficult to do.

SBGRZ2 finally got poured this week. After negotiation with the structural engineers I managed to place a delayed pour strip in the thinnest area of the pour. The reason for this was that the slab thinned to 4m wide a one point and it was assessed that the slab when poured would shrink in opposing directions as shown on the diagram below. This actually helped when it came to the pour this Saturday as due to the wet weather it was only possible to finish the slab, so we could concentrate on pouring up to the delayed strip location. The idea now that both halves of the slab can now shrink in their own direction without inducing cracking at the neck point, and the gap can be filled at a later date when the shrinkage has reduced to a minimal level.

More Rain

It has been a pretty slow week this week due to rain and wind which has resulted in approximately 2 days work on site. This is a severe blow as it means that the milestone pour of South Block, Ground Floor, Zone 2. There were far too many issues with the slab that it was decided to switch guns onto zone 6 as a more realistic target and hope that the client is feeling lenient and gives JHG the payment or at least, part of it. In my opinion, JHG has a terrible reputation with the Clients Representative so I expect them to just laugh and close their wallet. We will see what happens.

There have been 2 events of interest this week.

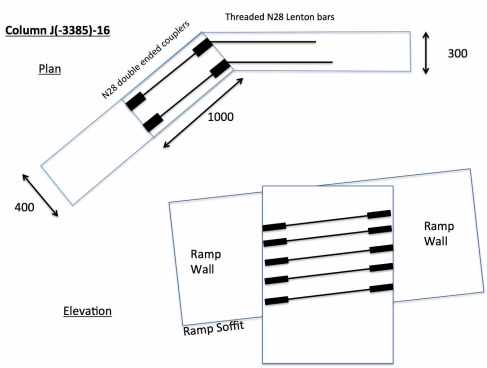

1. Column J(-3385)-16 is a 1000×400 rectangular column that sits along the side of the car park ramp and couples into the ramp slab. It also holds the ramp upstand wall reinforcement. The issue arose when it was discovered that the N28 couplers would not allow a threaded bar to follow the change in angle of the ramp wall. The options investigated were:

> Install straight threaded bars, then heat and bend to angle. (Structural engineer wouldn’t allow it as it was assessed that it would degrade the steel and there would not have the required bending diameter specified in Australian standards.)

> Short threaded bar with either short cog to allow it to be screwed in whilst formwork is in place. This would either have another coupler on the end, or if that wasn’t possible, a straight bar that could be welded to another straight bar to achieve the required lap. This option was dismissed as the manufacturer could only thread or couple a minimum of 250mm from a bend, and this would take the bar outside the perimeter of the wall.

> Break down the column to the underside of the ramp soffit and reinstall starter bars through the existing reinforcement. Messy and expensive, but appears to be the only way.

As it happens the weather has held back play this week, so nothing has been done to date. In my opinion, from looking at the structural design, the scheduler has interpreted the drawing incorrectly, scheduling couplers instead of starter bars. The bars were installed in line with the schedulers marked up drawing by the steel fixers, and the adjacent wall to the column formed up by the formworkers. To remediate this issue I have had to reorder the steel and column links (that will be destroyed during the breaking down of the column) and write site instructions for the steelfixers and formworkers to complete the work. This all has to be backcharged to the steel supplier who schedules the steel. It’s a fairly woolly reasoning especially as the steelfixers should have known better than to install reinforcement that wouldn’t work, and the engineer should have been more aware of the future intent with the column (But JHG won’t backcharge itself and it would be awkward to backcharge both the steelfixers and steel supplier so the scheduler gets it). It felt pretty dirty doing it as I have built up a good relationship with all parties, but it had to be done to get the situation moving.

The 2nd issue this week was the Health and Safety Representative for the formworker being sacked. The first that the South and Centre JHG teams heard about it was at the 0645 pre-start in the morning when the boys were all fired up and ready to mutiny. The root of the problem is all very childish as you would expect. Essentially the Northern formwork company, Crown, won’t let the Southern formwork company, West Coast Formwork, sit in the same lunch room as them (or vice versa). There has been a lot of playground tactics such as moving bags out into the rain, and name calling, but it ended in the WCF HSR heading down to the lunch rooms and essentially offering everybody out for a good old dust-up. Unfortunately for him, when he ‘threatened’ one of the rooms the JHG H&S manager was there and immediately had him removed from site for threatening behaviour.

I think JHG handled this situation particularly badly. Sacking a senior employee of a subcontractor and not at least briefing the JHG teams prior to the morning prestart. It was a difficult meeting as the rumour mill amongst the boys was working overtime and we had no information. You can’t reason with a mob. The situation ended with a meeting with senior JHG managers and WCF managers to no change. Relationships are now further tarnished.

In other news, we spent yesterday at a traditional Australian ‘Christmas in July’ party – strange, but good to have a hearty roast at this cold time of the year, and even more strangely just attended a first birthday party for a dog! If it wasn’t for the beers and BBQ I would not have gone. Still feel slightly dirty though.

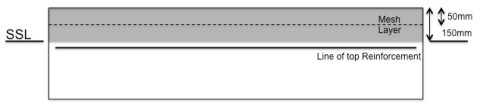

Chairing Mesh

It was decided that the building must be ‘futureproofed’ so one of the measures the architect has taken to ensure this is to pour integral topping layers to slabs so that if the intended use of areas in the hospital changes it will be easier to construct set-downs in the slabs without affecting structural capacity. This first manifested for me the day before the pour of the zone 4 ground floor slab in the South block where it was decreed that an additional 50mm of concrete would be poured on top of the existing structural surface level (SSL) taking the whole slab immediately to finished floor level (FFL). After discussions with the temporary works designer it was established that the falsework design did not have the capacity to support this additional load and could not be easily changed, so the pour continued to maintain programme. Future slabs are to have either a 50mm, 100mm, or 150mm integral topping layer applied to SSL in order to accommodate the futureproofing plan. This throws up several issues in addition to loading such as the placement of services (which were procured and tendered on a 2 stage pour, meaning that drains and ducts are no longer suitable and will require additional work to be completed prior to the pour and after to ensure that the design intent is complied with which will cost more money), and the additional cost that is incurred as a result of pouring quantities of concrete over the contracted limit.

The main issue for me was how to install the mesh at 50mm below the surface of the pour. In the 50mm topping it is not an issue, but for the 100 and 150mm toppings it will mean raising the mesh 50 or 100mm above the level of the top reinforcement. I discussed this with the designer, who hadn’t considered this issue, and the steelfixer, who didn’t want any additional burden (as he was already flat out on the remainder of the project). Due to the depth of the slabs, conventional chairs to raise the mesh were not adequate to do the job, therefore a custom solution was required. I investigated several options and used the scheduler and supplier to advise on manufacturing constraints. The options were as follows:

1. N12 Steel chair that could be inserted through the top mat or reinforcement and be tied to the B layer. An additional tie at the top mat would maintain rigidity and construction of a 1m square dummy bar mesh to support the mesh sheets.

2. N12 Steel Paperclips that sit on the top mat which would also incorporate a dummy bar mesh to support the sheet mesh.

3. Concrete blocks tied to the mesh to sit on top mat.

4. Trench mesh cut to desired height and bent into waves or rings, scattered liberally across the deck to support the mesh. This option came to me in a sudden memory from throwing in a half-arsed slab on ground construction during troopies course, using mesh rings to raise the lower reinforcing

Options 1 and 2 were decided to be both too much work and too costly. Option 3 was a non-starter really as it was reliant upon balance. Option 4, was decided as the best option for speed of construction and quality assurance. They are currently yet to be used on site but the first slab is expected to be poured by the end of the month. Currently I am procuring the strips through the reinforcing supplier at $7.45 each, but they are only able to supply a 100mm wide strip which leaves the 50mm solution unclear. After searching suppliers it will be possible to procure both solutions through a single source at a cheaper price but will involve flying the items from Germany. I am using the current supplier for the next slab but will be investigating the new supplier with commercial this week.

Union activity once again descended on site with another strike on Thursday. This is the second picket line I have crossed now, and find it actually quite fun. I managed to get in through the front gate this time as I arrived early before any padlocks were glued. Only a few of the JHG employees actually made it in on time, but the strike broke at about 1000hrs so everybody could get in then, though the lack of union members who actually returned was low so productivity took a hit. JHG doesn’t recognise unions and therefore can pay what they feel is required for a job (in this case low) which attracts non-Australian workers. From what I have heard, there appears to be a mindset change by construction companies in WA to unions. The number of sites in Perth that are union affiliated is dwindling and I think the unions are targeting the JHG NCH project, due to the scale of the project, in an attempt to regain the backing of the workforce. With the gradual demise of the mining boom it looks like in the future there will be an excess of labour which may crush the unions.

The senior management were aware of the intended strike but made the decision to continue with the pour. This resulted in 6 trucks of concrete that couldn’t gain access to site due to the picket line that were wasted (back-charged to the concrete contractor). At one point whilst chatting to the Project Director he said he was intending to place the traffic marshals out in the main road to stop traffic to ensure the trucks get in and the Police could deal with the traffic jam. I suggested that this would probably not endear the company to the community.

Other issues this week have been:

> The continued discrepancies between architectural and structural drawing details. Though it is understood that the nature of a D&B project breeds changes, I don’t think that JHG are managing the changes adequately. This wasn’t taken well by the design manager but hopefully will spark some action to ensure that these issues are caught earlier. There is a process for initial QA checks called the ‘Redstick’ process, where new drawings, which have been issued for construction, are run past engineers for comment. In theory this works well, but often there is just not the time to check the volume of drawings produced to the level of detail required.

> The reinforcement supplier not being able to supply the required N16 couplers for the ramp and having to supply N20s. Not a huge issue but changes all the reinforcement threaded bar in the ramp.

> Services clashing with beam steel. Memories from Richards lecture I think where services think they rule the roost. Beam trump toilet in this case. Architect….carry on.

> Subcontractors not even attempting to fix simple issues and resorting to firing it straight to the engineer. Couplers perceived to be installed too low for a header beam across a door in stair 8 internal wall but on re-measurement header beam soffit.

> inconceivable stupidity by trying to move an entire office across the road to a new facility and disconnecting the data connection prior to establishing one in the new office. By the time data was connected it had been over 24 hours. Certainly not acceptable on a project of this size.

> Another gratuitous crap concrete shot for Richard:

In other news I have signed up with “Team Ubique” for the Sydney Tough Mudder event. Jon, Myself and 2 other ex-corps lads living out here are going to participate in mid October (Now it is on here, it’s gospel Jon). I am hoping civi-spread has kicked in for them, though one being Will Gooderson, I expect not. Nicky and I went test driving a new Audi SQ5 this weekend, a good mornings entertainment but will probably wait till we get back to the UK to think about getting a new set of wheels. I did get some wheels though, I am now the proud owner or a 50cc hog. The MCI Riviera 50cc will roll from 0-60kph in approximately 2 days and will reach a top speed of 65kph. My mind drifts back to what a wise man once told me. “Mopeds are like fat chicks……great fun to ride until your mates see you!”

Self Made Issues

A temporary blip on the blogging last week where I just plain forgot, so apologies all round to anyone that reads them!

A few issues have cropped up over the last 2 weeks in and amongst the frantic push to meet a $20m milestone payment by the end of June. I think my last post eluded to the colossal amount of work that was required to meet the deadline and the equally large chance of a storm pushing through to make meeting it that little bit harder. The long and the short of it is that it was an uber busy week but we eventually poured the 4th slab in 7 days – for those of you who are interested, that’s approximately 100m3 of concrete. Good efforts all round.

The fallout from the epic push is that whilst all attention was focussed on reaching the milestone, very little was actually done to plan for future tasks. The following issues have arisen as a direct result of simply not have enough time/manpower to keep up with construction.

- Stair 9 Internal wall. The initial pours of Stairs 8 and 9 had many errors and were quite out of plumb in places due to an initial rush in the early phases of the project to get them poured. We have reaped the rewards of this by slowly closing out NCR’s with structural engineer input to bring them back into tolerance over the next few levels with no significant effects. The particular issue that could easily have been avoid was a lack of starter bars immediately next to the door (see image). I had a look at the initial setup of the formwork and discussed the missing starters with the steel fixers. I left it that if required, the error was theirs and they would have to drill and epoxy new bars in. As it turns out, they were not missing, the internal door had been set out wrong by the formworkers. By the time I had investigated this the steel fixers, pressured by site managers, drilled and epoxied and fixed the steel in the form. I had to order them to rip it out and cut the bars off when I found out. Sad faces all around. The issue now is who pays for the work conducted by the steel fixers. JHG won’t stump up because the work was conducted without JHG approval, so it looks like the formworkers will pick up the tab. I am speaking with commercial this week to discuss.

- Stair 10 Landing. When stair 10 was poured the couplers/starters were not installed as they were not delivered in time. The decision was to drill and epoxy new starters around the perimeter. A site instruction was written to the steelfixers to conduct the workswhich were detailed as N16 bars to be drilled 225mm into the wall (to internal edge of external steel) at 200 centres top and bottom of the landing. This work was completed and JHG informed that all work was in line with design and standards. On inspection it was noted that the bars were not at the correct spacing (but that could be put down to drilling around wall reinforcement) and also the ends were not aligned. ON closer inspection and a slight tug, a couple of bars came off in hand! To put this in context, the building is designed as a post disaster structure that feasibly could have a large imposed loading if people are rushing to evacuate the building. The landing is solely held up by the drilled and epoxied bars. This negligent work could have potentially caused additional collapse of the building. We are currently awaiting the outcome of a further investigation to ensure the work is completed adequately. To me this highlights the lack of personal pride in ones job and a complete lack of understanding of why they are doing something. It further highlights the problems with hiring 3rd tier contractors and the lack of any checks to ensure competence when hiring.

The hand removed N16 starter. Now I’m no good at estimating length (Nicky tells me) but that ain’t 225mm!

- West Block column. After the long drawn out negotiations with the client to decide the method an of pouring and finishing columns the following occurred 1 week afterwards. To top it off the Clients representative was at the stripping of the formwork with his Ipad looking for the density of blowholes in the surface finish – he got a bit of a surprise! It is assessed that the concrete was not vibrated adequately and the consistence was not sufficient. Therefore both JHG’s quality assurance and the concrete contractor for not carrying out the task correctly. The issue was escalated by the state to the WA Ops Manager who personally emailed the site engineer to express his dissatisfaction – not I would argue good management. A suggestion that it would be a good feature column in the X-Ray department was not taken well.

What this highlights to me is that a project must be adequately resourced to match the construction programme in both management and workforce. To not resource a project effectively is to delay the decision making process which will have a detrimental effect on progress.

The Construction Director who was pushing the programme (I think his job may have been on the line) has finally accepted that 2 engineers for the whole of the South block is simply not enough. A new engineer started who will be solely responsible for the Core C riser and jump form, and the rumour on the jungle drums is that a further engineer who was destined for the basement may be poached temporarily to reinforce the South team until the basement kicks off. Time will tell.

In other news, we had the Dollimore’s over for their last night in Australia this weekend. We had a fun night out with a few guys from the NCH to say goodbye, and a final breakfast at the beach in Cottesloe. Then it was time to head back to AER for me so I had time to finish in time for the Lions game. We set up the projector in the house and had a few mates over for a BBQ – Great game! Actually looking forward to work tomorrow now after the abuse I got last weekend!

Last minute design change

This weeks activity has been focussed on preparations to pour 3 suspended slabs by the end of the month to reach a payment milestone. This has been delayed by high level changes to task priorities that has affected progress. On setting out the first slab it was found that a 300×300 column that was set out to the architectural measurements was positioned on the edge of a slab edge-beam also set out to architectural measurements. The issue was that the structural design of the column assumed that it sat centrally in the beam and was therefore not sufficient for its current position.

This was raised as an RFI to both the architect and structural engineer to resolve the discrepancy in drawings.

The engineering issue here is that because the column was designed to be loaded equally the reinforcement is now not sufficient to withstand the additional bending. To resolve this there were 2 options.

- Extend the slab outwards to move the beam centrally on the column

- Insert a transfer beam to distribute the load between the 1000mm diameter column and the 300x300mm column.

Both of these options created issues. The slab reinforcement was designed to the structural dimensions, therefore was sufficient to accommodate the move out of the beam to sit centrally on the column, but the architect could not accept this option as it would affect the internal dimensions of the control room below making it too small for the intended contents. The second option required a redesign of the structure, rework to the formwork already placed, and the order of additional steel for the beam.

The decision had to be the transfer beam, which as it was designed could be designed to 450mm deep and therefore not affect the formwork already placed significantly. The steel was ordered immediately on a priority to arrive the following day. At the time of leaving site on Friday, all was in order and good to go – I will find out Monday I guess.

The managerial issue is that there was a discrepancy in the 2 designs (architectural and structural) that was not picked up sooner. The time it took to respond to the RFI took approximately 4 days after many to and fro emails between the architect and the structural engineer. A face-to-face meeting that may have taken 30minutes could have rectified this immediately. The final issue is that of costing. The cost of redesign of the beam should be borne by the structural engineer as it is the architectural design that measurements are taken from. Additionally the cost of the additional steel should also be covered by the structural engineer however the relatively small amount of steel required for the beam (3.5m long) will probably just be covered by JHG to maintain relationships.

In other news, the reorganisation is apparently underway and should be in effect on Mon. The notice period of the weekend is probably not enough time for a full handover so I am expecting a fair degree of turmoil this week. It has been good to catch up with the Knowles and Dollimores this week at their leaving parties, and we are having a RE BBQ at ours this week as a final send off.

Concrete Quality Issues

The dispute on the surface finish for upper basement columns has apparently been settled, though I am not too sure it has really started yet. The tender design specified grade 3 columns throughout the building as from ground floor up they will be sheathed and those levels below ground were only going painted for the car parks and storage areas so there was no requirement for anything better. The intention to paint the car-park columns was decided to be a maintenance issue (questionable) and that the columns should now be bare concrete. About 2 months ago the clients representative (CR) said that the finish on the basement columns was not suitable, and though it easily met the class 3 finish it was not quite what they wanted. The CR have promised to submit a variation order to change the spec from Class 3 to Class 2 but this is still pending. The initial issue was with the spiral “Ezy-Tube” forms giving a spiral effect on the outside – though not anything to do with the surface finish (concrete wise) it was really the catalyst. So the last few months has seem several test columns poured to reach the fables grade 3 column with a grade 2 look, it didn’t happen and was beginning to stall progress.

The decision by the construction director was made to purchase grade 2 forms (GSC) and provide 5 test columns (1.2m sample height poured and vibrated in different manners for the CR to choose from – the fact none of them had rebar in made the test fairly nugatory mind). This produced a definitive sample which was then required to be tested on a full column to produce a standard column from which to work to. The column was poured using the standard 65MPa, 20mm Agg, 150 Slump column mix but with a slump of 190mm which in my view is out of spec according to Aus Standards (>150 = (+or–) 40mm). This soup was always going to give a good finish and the addition of 10 minutes of vibro-poker action cranked up to 11 just finished it off nice.

The resulting test column is magnificent, it is so smooth I could lick it (it is clearly Class 1), but the additional vibration has clearly had an effect on the structural capacity as there is no way that 10 minutes of uber-pokering could not have the effect of separating the large agg to the bottom and the small agg to the top. This is apparently falling on deaf ears as JHG attempt to suck up to the client promising something which in my opinion we will never produce again, well not on my watch – I have been quite rigid on concrete spec and will no doubt get my arse chewed shortly for turning away too much concrete! (60.7m3 from 1336.7 so far (4.5%)). I am gaining commercial experience of how to pass the buck though.

I called an on-site meeting with the Quality Manager to discuss this issue and asked him to transmit to the CR the annex from the Aussie Standard that showed images of the surface finish grades as I do not believe that they even know what they are.

We were ready to pour 18 columns on Zone 4 on Tuesday but were held up by a 500m3 pour in the North. Unlucky really as the CR mentioned to me whilst on the deck that they had received no correspondence from JHG with reference to the column finish and that if we were to pour it would be entirely at our risk and we could be made to rip them out and start again if they were not happy. Strange really as JHG contractually carry all the risk anyway but stern words all the same. They also stated that they required confirmatory test columns to be poured too. This was conveyed to the upper echelons of the NCH and it was decided to pour 3 more test columns.

The pour was started on time for a change, but the first test I did on the mix gave a slump of 230mm so I immediately retested as per AS and got 220mm so turned it away and got the next one on. It was tested at 230mm and then 220mm so I turned it away too. I spoke with the concrete ninja at the supplier and he said it must just be a bad batch as both drivers claim not to have added additional water. The pour was aborted and rescheduled for the afternoon. This pour went relatively smoothly with a 140mm slump (added 10l to the mix to bring it to 160mm, and a 160mm slump for the next truck) and 3 columns plus a ramp wall were finally poured.

All the detail about quality mentioned above said, the columns were stripped this morning and I would assess them as high class 2 so pretty happy considering. Now I just have to deal with the admin of turning away vehicles and the fact the pump operators decided that blowing out their slurry mix onto the access slab was a good idea.

In other news the rumour mill is in overdrive as the management have decided to re-organise the teams to inspire better teamwork. This has been widely conveyed yet with no detail, so everybody is in limbo. The only definite is my comrade in the South who is moving North, so I fully expect the workload to increase as he goes. The unions have started a new campaign, portraying JHG as a circus, including a ringmaster and animals – actually quite funny.

Nicky and I also went to cheer on the British and Irish Lions on Wed, fairly average game and pretty poor stadium for an atmosphere, but town was alive and good fun – still on the hunt for tickets to the 3rd test, so keep your ears/eyes open please.

Milestone hit!

This week has seen yet another significant concrete pour, and actually a milestone we hit! Once again there were several issues though. Reliance upon the sub-contractor to do what he is meant to do is actually more of an issue than it would seem. I have organised pre-pour meetings with all the involved sub-contractors and managers in order to inform, discuss and resolve potential issues for the last 5 suspended slab pours (I even have an “Actions On” section in the minutes) but it appears that no matter what is decided the contractor tends to do what he wants to anyway. This recent pour of Zone 6 was no exception. It was a relatively large at 330m3 and incorporated a mix with the addition of Xypex for a small area of the slab. It was to be pumped from the semi-permanent concrete pump in the slip-lane through about 130m of 150mm diameter pipeline on the boom mast. The issue with this pour is that the 3rd mast is not yet operational, and therefore the 2nd was used which didn’t quite have the reach (this meant time consuming pipe connecting, and the inevitable blockages each time).

The pour was due to start at 0700 but due to rain during the night, the client declared that the falsework required an additional inspection before the State was happy to sign off on the pour card to let the work commence. This delayed the pour to 0800. The pour was then delayed to 0900 as the concrete sub-contractor had not moved the required tools across the night before (as agreed in the pre-pour meeting). As the concrete arrived there was a brief shower of light rain which resulted in the concreters retiring under cover stating that they don’t work in the rain. This added an extra 30mins to the start, whilst I had to call the sub-contractor to sort the situation. Once the inevitable blockage was cleared the pour started at approximately 1000. I was not considerably worried about this, as I know that once the pour has started it will continue until complete and it really will be a case of “You’re in your own time now.” So the incentive was on them to work efficiently. As the pour progressed I became increasingly aware just how lethargic the concreters were, there was just no sense of urgency. Concrete was continually at the pump throughout the day – I was actually pleased with the JHG performance during the day – yet it just wasn’t being placed as quickly as required. The pour finished at 2030, approximately 10.5hrs after starting. JHG laid on pizza for the late workers, but I decided that I was not going to wait around until they had finished the surface correctly. They eventually finished at 2330.

On inspection in the morning it was clear what an awful job had been done. Unfinished surfaces, badly floated surfaces, holes in the top, aggregate showing, undulations in the surface, and even footprints. I had a walk around with the camera to record the post pour inspection. The most striking issue was with the use of Rugasol. Rugasol is a chemical agent that prevents the cement past bonding with the aggregate to a depth of about 4mm in order that post pour the construction joints at column tops and upstand walls can be water blasted to a good scabbled finish instead of chipping them out. The rugasol application on zone 6 was pretty liberal, and not confined to the columns and walls. This coupled with the undulations meant that the fluid had spread around the CJ’s damaging large areas of the surface. I raised all these issues with the PM and Site Manager, supplied the evidence and then sat back as they went into battle. The remainder of the non-conformance points will be raised in the project pack for resolution.

During the recent concrete pours I have become aware that the management of the pour is dominated by JHG personnel, who take a lot of abuse for pretty much any issue. I was not overly happy with this as it is usually me that takes the brunt of it. Whilst I was delving into the sub-contractors contracts to build the cases for later arguments about the NCR’s I noted that the concrete sub-contractor was actually responsible for calculating concrete quantities, receiving concrete onto site, and managing the actual pour and that the concrete supplier should have a representative on site to manage the trucks. I proposed to my PM that the concrete pour is broken down into stages.

- Preparation. Managed by JHG. Engr continues to calculate concrete quantities and types. Site Manager orders and briefs sub-contractor of when it will occur. Pre-Pour meeting as normal.

- Delivery. The concrete supplier is responsible from batching to delivery onto site. He manages the trucks ensure that no more than 3 are waiting in the slip lane at any time (Maximum allowed in Safety plan). The concrete sub-contractor receives the trucks and marshals them in order to the pump. The JHG engineer tests to ensure quality.

- Placement. The concrete sub-contractor is responsible for the pouring of concrete and calling in the excess to finish the slab as necessary.

Risk-wise, I think JHG had put too much on the line by involving the Engr and Site Manager so heavily. The sub-contractor is being paid to take the risk, so he should take it. (By all accounts they are actually quite keen to do it). I have drafted a concrete management plan that I have thrown around the Engrs and Site Managers and will submit to the PM this week to get it signed off. Nothing official really, more of a Memorandum of understanding to ensure that the sub-contractors are aware of what their responsibilities are. There is even a task-org in it. I think the Sync Matrix was pushing it!

WA has its fair share of public holidays, so Nicky and I have made the most of this long weekend by driving down to Margaret River, 3hrs south of Perth to spend some time with mates in the wine and surf region. I finally managed to get in the water on Sunday. It wasn’t as big as I would have liked, but the reef that was only 4ft below the waterline was incentive enough not to wipeout too heavily – Success, you’ll be pleased to hear. We returned today with a heavily laden car full of wine and a very unheavy wallet. This week sees the British and Irish Lions visiting Perth. I don’t think productivity in the site office will be high on Wed afternoon. Nicky and I are catching up with Steve and Fay and a few other mates, so it should be a good night. Having attended Western Force’s fixture last Saturday, I do not predict any real issues for the Lions. Potentially a 3 figure score.

More Slabs, More Safety

Finally we get the go ahead to pour Zone 5 Upper Basement slab. The contractor found that his pumping strategy didn’t work on arrival of the mobile pump so changed the plan. It then involved a mobile pump and about 35m of hose. This wouldn’t have been such an issue if they had started from the back and worked forward but due to the restricted angle to pump could boom it meant that we had to start at the front and work backwards before coming back again. In all, it was a very awkward pour. From the pumping location I noticed that there was likely to be area that would be left for several hours before the pour line met it once again. After the issues of the last slab I was involved with I did not want this to happen, so called the JHG supervisor to remind the subcontractor of this issue. It eventually took the movement of a kibble from the other end of the site and a commandeering of the crane to get some concrete down and keep the edge alive. As the pour was ending the supervisor called forward to the batching plant with his excess to the ordered quantity, to ensure that the pour did not go short, expecting the final programmed truck to arrive. It didn’t, the concrete batching plant had decided to retain the last 5m3 of the mix to send at the same time as the excess. Why?! If somebody has ordered concrete, why wouldn’t you send it! This resulted in a further hour delay in pouring. The whole pour took about 7 hours, and the concreters were still there at 2000 finishing the surface.

The surface was not good. It appears the concreters got bored about 2000 and went home. This initiated the next phase of my week – Getting involved with quality control. When a task is not performed correctly a Non-Conformance Report is raised detailing the issue to the contractor and asking for their rectification methodology. Unfortunately Crown (Concreters) have been at the end of my wrath this week. A poorly finished slab and then I found some reinforcement sticking through the surface of a poured slab. Actually the client found it and asked if I had, I went down for a quick look so that I wasn’t lying when I emailed a reply that I had. This formed the second NCR for Crown. Subcontractors don’t want to pay to remediate their own poor work, they would much rather we sent them a site instruction so they can be paid to do it. The backlash to my NCR’s was interesting, I was surprised that “The dog ate it” didn’t feature in the reply. I stuck to my guns and quoted contractual points that they are responsible for the finish no matter what and that if there are issues with the reinforcement they have a duty to raise it during construction. As yet I have had no comeback to my last.

We finally poured concrete using the Boom Mast on Friday. The pipeline that was serviced by a semi-permanent pump in the slip-lane was finally plumbed in and was tested on the columns in SB Zone 2 in order to set the conditions for pouring of the ground floor slab with is a milestone for May (not likely). Things actually went quite smoothly for a change, apart from one column requiring formwork remediation and mixes changing from 65MPa to 40MPa and back again – not ideal but necessary.

The final parting shot of the week was from the concrete boom mast, that decided to shed its top ladder (approx. 200kg) when it was being put away. The ladder fell approximately 20m onto a thankfully empty deck (at 1700 on a Friday site was effectively a ghost town anyway). Cue ComCare on site once again Monday morning – they may as well get an office here! The investigation is ongoing.

This weekend was spent dashing like warriors around a 5km muddy obstacle course. The RE contingent (Steve and I) was strong, and we both managed to rope our wives and a couple of lads and lasses from work in too. I was so enthused that when I returned home I signed up for a 20km version in October – apparently this one is a bit tougher. I think I may miss the green a little!

The Storm after the Storm

Monday – Rainy/Stormy

Tuesday – Rain/Stormy

Wednesday – Rain/Stormy

Thursday – Patchy Rain/Windy

Friday – Sunny with spells of rain.

So, even though, over half the workforce is Irish, Tradies in Australia don’t work in the rain! I think they must melt.

The Zone 5 suspended slab sits quietly rusting in the South, and now the clients are unhappy that there are rust patches on the formwork. This was also an issue with the Zone 4 slab but after negotiations at PM level, JHG eventually issued a site instruction to the formwork contractor (who is responsible for a daily blow out of debris (including tie-wire) from the slab) to powerwash the deck. It visually made bugger-all difference but there are minimal rust marks on the soffit now the formwork has been stripped. On the stripping of formwork, I did think it was rather open beneath the slab and pretty soon realised they had stripped all the backprops. I asked the question of the formworker whether he thought it wise to strip all of the propping from a suspended slab on which they were forming the next level on, but he seemed fairly unfussed that he was stood under a loaded, unsupported 3week floor. I pointed out the requirement for backprops in the design and sent the email to ensure it was rectified.

The big news for the week is that the structural engineers report into the Zone 3 concrete has come back and indicates that although the concrete is not to the expected strength and exhibits de-bonded steelwork and delaminated aggregate in some places, these places are in areas of contra-flexure and therefore any remedial work to the slab may in fact make the situation worse. This is a massive bonus as I was expecting to see Sappers down there chipping out concrete with chisels. We can now forge ahead and form up the columns and decks and push onto ground level.

The rain did very little to affect the programme, it only affected the amount of work completed during the week. Therefore milestones that were set to be complete in May remain where they were before the inclement weather and Strike action. This increased pressure on Engineers to hit targets doesn’t really transmit to the tradies though who continue to amble along at their normal pace. Frustrating.

The phrase that has been thrown around most of the week is attributed to one of JHG’s senior managers who stated during the planning for the NCH that “It doesn’t rain in Perth so don’t factor in that many days for wet weather.” Sensible. This decision was also made at a similar time as the one not to build in days for strike action – we currently sit at about 25days in just over a year lost to industrial action.

I organised a meeting with my PM this week to discuss a few issues that had arisen over the last few weeks. I put my suggestions to him as positively as possible in an effort to make them heard and maybe effect a change in the team structure. They were:

- A weekly mid week meeting to RAG status the Short Range Programme in order to proactively manage and focus the effort of the team for the following days to meet the level 3 milestones. Currently the SRP is slipped weekly and I don’t think there is any buy in by the engineers as there is no real incentive the aim for milestones if they are all verging on impossible from the time of publishing.

- Following on from point 1, a team review of the SRP to set realistic targets that will be bought into as everybody would have had a role in the planning. I quoted the Project Director who said “I realise the SRP’s are near impossible.” By having a programme that is not achievable, targets are continually missed and this damages team morale.

- Following on from point 2, we need a team social. Time is obviously short so a day out of the office is not feasible, and nobody would go for a weekend, so I suggested volunteering for a charity for the afternoon (assisting in local image and sustainability targets set by JHG) or at the very least a team lunch for 2 hrs once a month. I had also noticed that in the pub down the road from my house there is the 141 challenge (141 beers to be imbibed by a person or team in the shortest time possible – 28mins seems to be the record, so must have been a huge team or big drinker, but days seems quite common). Probably not in keeping with the 0% tolerance on alcohol on site though so maybe this is just one for after my TMR submissions.

The overall thought on my suggestions was that they are not new, there are changes in the pipeline, and a monthly lunch would be good. 1 out of 3 isn’t bad. I am still planning on a daily “RAGing” of the South area as a method to highlight the risk to the Snr Engr and PM.

So the Stormy weather has ended in time for the weekend, now the next couple of weeks look set to become a thrashing to meet the milestones that are in danger of being missed.

On a brighter note, I have just fired up the BBQ.

A very unproductive week.

This week started in the normal manner of Mad Monday where everything that was meant to be done over the weekend was started on top of the planned works. The focus this week was on the continued preparation of the Zone 5 suspended slab and column, wall and ramp fixing in Zone 2. The slab finally started on Mon, after the calamity of reo deliveries last week, but was held up by cranage moving the bottom mat across from the slip-lane. Zone 2 is more of an issue. Drawings issued on the same day by both the architect and structural engineers differ in their portrayal of the detail around the ramp and were missing detail on slab set-down levels which dictated soffit levels for slabs and beams. After several RFI’s to the Architects I received a satisfactory answer for set-down levels which allowed work to continue but a vague and pretty non-committal response on whether a wall was ramped or horizontal. This matter is still open.

I received an email from the concrete testers stating that the 3 and 7day tests on the 65/20/140 mix used for a column poured last week were significantly understrength. My initial response was to investigate with the tester what the expected final strength would be and whether the mix was as designed and noted on the docket. This was confirmed and it was suggested that it may be a mix that was on the lower percentile of the range. It may reach the approximate strength after 56 days but the question now is whether the risk can be taken to accept this or whether remedial work is required. I forwarded all info to the structural engineer to investigate the situation and recommend a course of action. In my view, as the column forms a corner of a vertical stairwell that is tied into the slabs it may be possible to increase the reinforcement around the connection in order to minimise the loading on the column. This may be the best COA as it will allow construction to continue with minimal rework, and if the column does not reach the required strength it will have an element of redundancy built in to assist in carrying the load.

Tuesday was largely spent in preparation for the work I would not be able to complete during CI’s visit on Wednesday. I think the visit went well and I imagine the change in the site since the CI’s last visit was considerable. From my perspective it was good to talk through the project and highlighted just how much I do actually know about it.

Black Thursday

During the later stages of the CI’s visit we became aware of an altercation between one of the contractors and the JHG H&S representative. This must have escalated after our departure from site as on arrival at site on Thursday there was a significant union presence at the main gate. I had no dramas getting into site though. The lads had more of an issue and the pre-start was lacking numbers. As it happened the rain had effectively stopped play on site (Aussies don’t work in the rain!) which pretty much negated the strike outside. The issue can about 1100 when it was noticed that there was a small fire outside the cab of Tower Crane 2. The operator raised the alarm and evacuated effectively, which resulted in a full evacuation of site. This would not usually be an issue but the fact the union was camped out on the assembly area 1 and after H&S closed the slip-lane (assembly area 2) to access from outside site it meant that the Union propaganda machine whirred into action to get as many photos of their ‘massive’ turn out until we managed to gain access to assembly area 2. The incident was handled well from an operational perspective with the Fire-service on the scene within minutes, but in my view the JHG information flow to the workforce was lacking and the fact a contractor took charge of information passing was a little embarrassing. Work was later put on hold, and eventually stopped for the day (for the lads). A team meeting was called by the PD who briefed that an anonymous text had warned him of a Picket Line for Fri morning.

Quiet Friday

I planned on arriving early to avoid the masses so parked up my bike at Steve’s and walked down to site. It was relatively quiet along the main road, but as I approached the main gate there were about 12 union blokes blocking the path. I weaved my way through to find the gate locked and padlock injected with glue. A couple of choice words and a push in the back and memories of Ex Broadsword flooded back. I walked back along the fence-line and was let in through a manned gap in the chain-link. I have spent the morning walking around with a H&S as the site has been locked down and everybody told not to bother coming in. So I am sat here with my fellow 10 JHG inmates listening to the Union songs and chants whilst the remainder of the staff have a day off. This had better be remembered come report time. I just hope I can get out in time for my flight to Melbourne this afternoon.

So in effect, I have worked 1.5days this week. It is lucky the CI visited when he did – what a difference a day makes.