Archive

Industry Lessons Learned?

I received the following document (Dated April 16) this morning. At this early stage there is nothing to prove (That I have heard) the recent tragic accident is related to the issues outlined in this report. That aside, in the continued interest of professional competence and safety going forward its definitely worth a quick read.

Foundations in congested ground

EXP-487-SK002 – In ground services clash review BH responses TS markupI’m looking at the foundations for a new elevated walkway at Wembley Stadium. The ground is pretty congested with services thanks to those pesky M&E critters. Needless to say the SSPs are saying it’s absolutely impossible for them to abandon or move anything so i’ve got to bridge over them. Anyone got any references for good guidance on these issues?

Update following RFs comments:

This is just conceptual considerations however, linked

(randomly inserted at the top of the page) is the latest of the clashes discussions I’ve been having with the services coordinator. My current aim is to work out if the foundations are achievable, meaning identify the types of problems we have (eccentrically loaded pile caps, services under pile caps, services adjacent to piles/caps) and say what the possible solutions might look like.

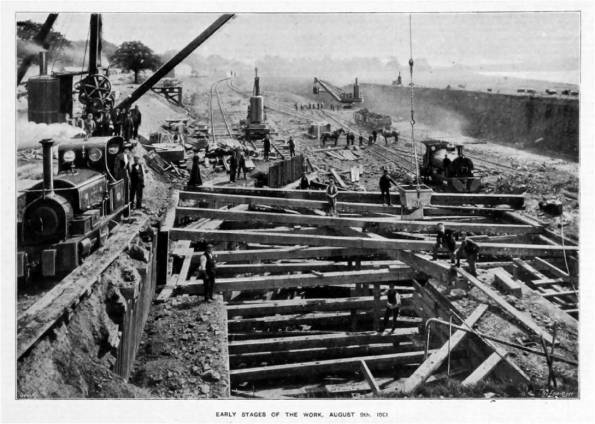

Construction – has it really changed?

Most of my time with RPS Consultancy has been spent analysing existing historic dock structures. I have been working on a design and build project to construct new infrastructure for the Royal Navy’s new frigates in Glasgow. In order to make alterations to the dock structure it is necessary to understand how the existing structure works. As a result, I have spent a great deal of time trawling through old literature sourcing information.

Recently, I found the following photos of the construction of a dry dock in Scotstoun in 1903. It occurred to me that, whilst there is no hi-viz and no fall protection, very little has changed in the world of construction.

Coincidently, my principal take-away from this analysis is that modern design codes are overly conservative. According to Eurocodes these docks should not be standing.

Dry Dock 1 – 1903

Dry Dock 1 – 1903

Dry Dock 1 – 1903

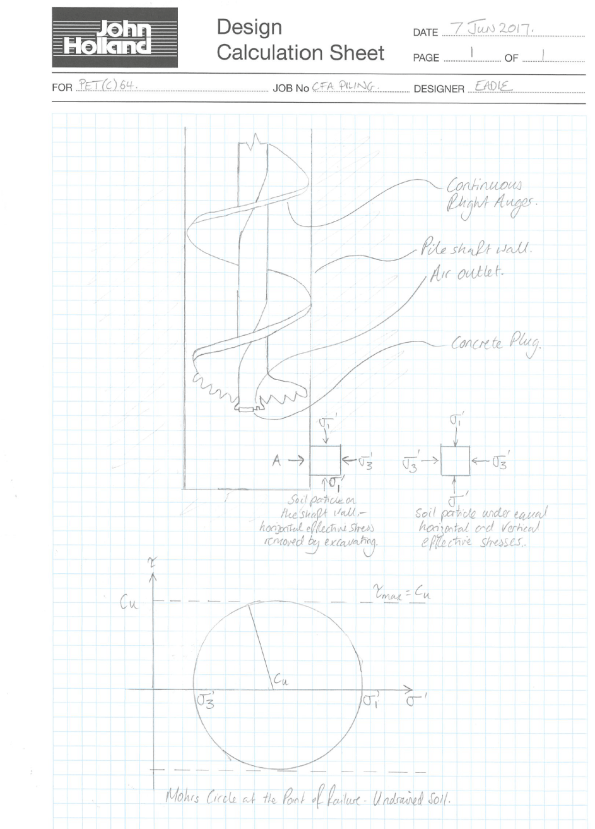

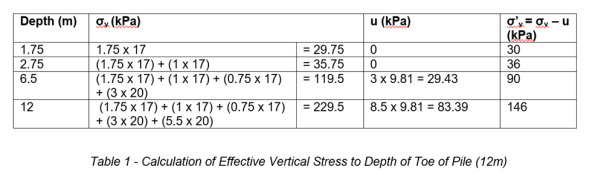

Stabilising Continuous Flight Auger Pile Excavations with Compressed Air

A commonly used piling method in Australia is continuous flight augering, with an experienced operator it can be relatively simple to install, cost effective, with limited noise and vibration.

The interesting aspect of CFA piling by AVO is their use of compressed air to stabilise the excavation. Avo use a Bauer BG 24 rig, which has the ability to inject compressed air from the tip of the auger. Compressed air is injected near the discharge pump at 150kPa increasing by 100kPa for every 10m of depth. The pressure helps maintain the stability of the excavation prior to concrete being introduced through the stem of the auger.

As the soil is excavated from the pile shaft, the horizontal effective stress (σ’3) on a soil particle on the shaft wall reduces to zero. The air pressure applies an equalising horizontal force to the walls of the excavation of about 250kPa, this is larger than the 146kPa which is being exerted by the soil around the shaft near the toe (see table 1). The air pressure helps stabilise the excavation from collapsing by applying a passive force against the active force from the soil around the shaft walls. Excess pressure is forced up the shaft helping lift soil up the flights of the auger.

This method helps increases the pile skin resistance by limiting voids along the pile shaft.

How quick is base heave?

Battersea Station Box is a top down method of construction; we are currently excavating in London clay and blinding in order to fix steel prior to pouring concrete for the propping structure. The first blinding was poured about 4 weeks ago and what at first we thought were surveying inaccuracies appears to be the concrete blinding heaving. We have excavated about 10m of soil so the total stress will have reduced by about 200kPa.

I believe there are two forms of heave, elastic rebound and swelling. The maximum rise in the blinding is currently about 10mm, and we are now trying to track the rise as it appears to moving about 2-3 mm a week. I am surprised that this is happening over such a short time frame and as we are casting primary beams prior to digging down again we risk the soffits being out of tolerance.

Currently all I can surmise is over such a short time frame it is elastic rebound rather than swelling. Swelling is due to changing effective stress due to unloading and the change in pore water pressure which I would have thought would take place over a longer period.

The GDR only quantifies heave in relation to pile design and the pressure it will apply to the base slab in the long term (drained), it mentions short term relaxation but does not quantify it.

Has anyone come across a similar situation before?

Freds Giant Crane

I acknowledge that my last blog bored most of us to tears, so this Friday afternoon just before the office beer fridge gets cracked open for the weekend I thought I’d follow it up with a topic even the E&Ms might enjoy.

Hopefully some of you will remember Fred’s blog a few months back in which he essentially implied he had designed use of one of the worlds largest land based crane systems during a morning coffee break. I had the joy of visiting Freds crane earlier this week on CPD. It really is impressively large. See below some photos and a few basic stats I picked up whilst there.

Its currently supporting removal of very large reinforced concrete beams as part of the demolition job on the Earls Court Job. The demolition package alone, including this crane, has a contract value circa 28 million quid.

![IMG_5113[1]](https://pewpetblog.com/wp-content/uploads/2017/06/img_51131.jpg?w=595)

In its strongest configuration the Crane can lift 5000 tonne. On this project the greatest load they will lift is just under 1600 tonne.

The load is transferred to ground through steel pads onto a compacted earth foundation and generates a bearing stress of 0.28MPa.

![IMG_5111[1]](https://pewpetblog.com/wp-content/uploads/2017/06/img_51111.jpg?w=595)

Giant lifting tackle, required just to assemble the crane.

![IMG_5115[1]](https://pewpetblog.com/wp-content/uploads/2017/06/img_51151.jpg?w=595)

The crane moves when the grey hydraulic jacks drag the legs along the rail. The silver disks are Teflon pads which create a low friction channel. The gang genuinely lubricate these runners with washing up liquid before each move.

![IMG_5119[1]](https://pewpetblog.com/wp-content/uploads/2017/06/img_51191.jpg?w=595)

The crane has a maximum operational reach of around 130metres. At this range it can lift approximately 300 Tonnes. When you consider a standard tower crane can lift roughly 3-4 tonnes at a maximum reach of about 70m these are impressive stats.

All these fancy figures aside, for me the most impressive implication is that deciding to use this crane has saved the sub contractor, or so they say, 3 years on their demolition programme. I hope the person who actually came up with this plan got an appropriate bonus for his lightbulb moment!

Baggage System Failure at Gatwick

For those who may have missed the news on Fri 26 May 2017, (note civvi date structure) there was a significant failure of the baggage system at Gatwick Airport which made national news. I will also share with you how BA managed to significantly divert media attention away from the baggage failure by their ability to seriously curtail the duration of their customer’s holidays.

Well, let me start by saying that the baggage system failure was not my fault despite the early conclusions drawn by my peers. The aim of this Blog is, to set the record straight, to regain control of my reputation as a polished E&M engineer, to give you an insight into how an airport baggage system functions and what went wrong on that fateful day; known as Bag Friday.

OVERVIEW OF THE BAGGAGE HANDLING SYSTEM (SOUTH TERMINAL)

To be able to describe the baggage system failure it is appropriate to give you the reader an overview of the mechanics of the Baggage System employed at Gatwick.

Meet Martha in Figure 1, she is a shy Check-In technician who takes control of your baggage at the Bag Drop. The bag is weighed and a bar-code is attached to the bag before it starts its very own journey through a myriad of conveyors, scanners, sorters and physical abuse sustained from the baggage handlers. The bar-code contains a list of descriptors which identifies you to the bag, flight details, destination, weight (of the bag), flight times and so on.

Figure 1 . Check in desk and Martha.

Your personal details are derived from your passport and tickets which are communicated to various agencies both internal and external to the airport. Internally, an individual’s personal data is forwarded to the airline which will checks you onto their flight manifest and central database for use of tracking and marketing purposes. Externally, Customs and Excise are alerted to you checking out of the country; their database is linked to the Home Office and shared with annexing databases owned by UK security services (this is applicable to both manual and on-line check in). In short, if an individual is on a Home Office ‘Watch List’ then basically he/she will be interviewed at the airport as they pass through security.

Assuming you are not a terrorist, your baggage is permitted to enter the baggage system. The bag is currently at Level 1 (blue insecure) and the Baggage System (governed by an Oracle database) is expecting the bag to arrive at the first scan point to perform a ‘handshake’ with the baggage. The scan is a function performed by an Automated Tag Reader (ATR) – the four blue boxes elevated above the conveyor shown at Figure 2. No matter where the tag is positioned on the bag and however the bag is oriented on the belt, the ATR can locate, read, and decode the bar-code achieving up to 99.8% read rates even for damaged or poorly printed codes. If the tag is unreadable, an operator removes the bag from the conveyor and then manually codes the bag into the Oracle Database and reintroduces it to the conveyor.

Figure 2. 4No Automated Tag Readers elevated above the inbound conveyor.

The ATR also scans the orientation and size of the bag, from this point forward the bag will be physically rejected from the baggage system if it has moved over a tolerance of 20mm on the assumption it has been compromised. For efficiency, conveyors default to idle when not in use and also the speed of conveyance is governed by Programmable Logic Controllers (PLCs). Each of the conveyors have a dedicated PLC gate which notifies the next PLC and so on to guide the bag through the conveyor system. The PLCs also feed data to the central Oracle database which tracks the bag’s progression through the baggage system.

The next step is to scan the baggage for illicit material. The Level 1/2 scanners perform an automated check in under 3 seconds and if satisfied with the contents, the bag is permitted to progress onto the next stage. The level 1/2 scanner is shown below in Figure 3; note the Level 1 blue conveyor presents the bag to the scanner and emerges on to the red (scanned) conveyor on the far side.

Figure 3. Baggage Scanner detects illicit material within the baggage.

The bag is passed to a vertical sorter (a decision point) as shown in Figure 4. The bag is either permitted to progress onto the next stage or a PLC command will force a transfer to Level 3. At Level 3, an operator has 15 seconds to check the bag on their screen and if the operator is unhappy with the contents, the passenger is summoned to open the bag for a Level 4 manual search.

Figure 4. The vertical sorter allocates the bag to either Level 2 or 3 conveyors

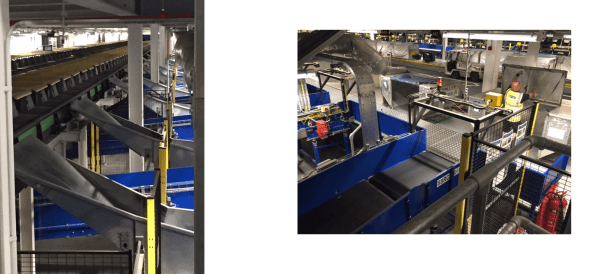

Assuming the bag has successfully cleared level 2, the bag is allocated to a tip tray conveyor as shown in Figure 5. PLC logic controls the speed of a delivery conveyor to ensure the bag’s approach is synchronised with the tip tray. The chutes also shown in Figure 5 are dedicated to particular aircraft, when the bag arrives at the appropriate chute it drops down to a Make Up Position where a baggage handler loads the dolly (bag truck).

Figure 5. To the left is an image of the Tip Trays and Chutes. To the right is an image of the Make Up Positions

Figure 5. To the left is an image of the Tip Trays and Chutes. To the right is an image of the Make Up Positions

SO WHAT WENT WRONG ON BAG FRIDAY?

To understand the error you need to understand how a baggage Oracle database works. The central Oracle database manages the automation of the baggage system which is fed data from a vast array of PLCs distributed across the baggage network. The database stores the data into tables which dynamically increase/decrease in size in relation to the amount of data accrued by the system. The data tables are called ‘Stacks’ and have a limited capacity before they start to overflow and discard data.

A bespoke programme queries the Oracle database and presents the baggage system performance characteristics to the Building Management System (BMS). BMS is a Graphical User Interface which can manually or autonomously manipulate mechanical systems around the airport, such as the baggage system and also the air conditioning.

The communication path between the Oracle database and PLCs contributed to Bag Friday. The PLCs fed data to the Oracle Database, however due to latency issues in the communications network, the database was receiving data spikes causing the Stacks to increase in size beyond their maximum capacity. The Oracle Database became overwhelmed and gave a stop command to the PLCs which in turn closed down the baggage system.

As a consequence, within 7 mins of failure the Check-In desks were closed and puts the airport on alert status ‘Bronze’. At 45 mins the Arrivals and Departures fills up with passengers which heightened the alert status to ‘Silver’, at 90 mins cars on the M23 and M25 were backed up and Gatwick hit the headlines. The baggage system was down for just under 3 hours resulting in a total of circa 3000 bags remaining in the terminal, later repatriated with their owners at a cost of approx. £150 per bag.

WHAT HAPPENED TO BRITISH AIRWAYS?

BA tweeted to the media that they have a data HUB near Heathrow that lost power; one would suggest they should have factored redundancy into their power supply if indeed this was the case. According to a senior BA rep at Gatwick, the actual reason for the their system to collapse is because they sold their operating system to India to reduce costs! BA operate on a Virtual Local Area Network (VLAN) which allows their operating system to be placed anywhere in the world. Situating an entire Operating System on a VLAN is a sound concept and common place for many multinational companies, however in the case of the BA system failure, the link from OS in India to the satellite ‘dropped out’ to the Master/Slave servers. The failure caused their entire management system to collapse, grounding all aircraft, ceasing all bookings, aircraft tracking and configuration of flight manifests. The entire fleet had to re-set to a start state two days out from the time the failure occurred.

In summary, the issue with BA overshadowed the Baggage failure at Gatwick, therefore we owe BA a great debt of gratitude.

Pingo Bingo

Last week Beresford tricked me into attending what I thought would be a notoriously dull lecture at the Royal Society of Geologists. The talk was on a ground condition known as a Pingo, or using its more technical name, Drift Filled Hollows. It turned out to be mildly interesting because the ‘expert’ openly admitted that Geological understanding of this condition remains relatively basic at the moment and from engineer’s perspective, the implications for a large structure are potentially very severe.

To try keep this short, a Pingo is basically an unexpected disturbance and variation in the ground strata caused by (they think) perma frost occurring in the ground some millennia ago. This created a hole which is then essentially filled with differing material over time. In the London Basin this is an issue because it means, where you might expect to find a decent band of London Clay there could actually be a column of terraced gravel, or another material, penetrating to significantly greater depth.

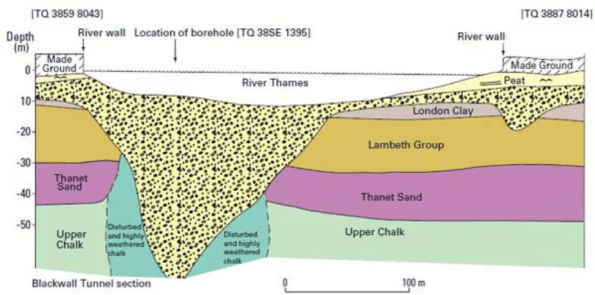

The following image shows a cross section of the anomaly discovered during the Blackwall Tunnel project.

Some of these anomalies have been found to be more than 90m in depth and have relatively small surface areas. This is potentially a problem because if you insert a large load bearing column designed to use skin friction from the London clay, Lambeth group or Thanet sand, and it actually sits within a deep column of terraced gravel, the performance of the pile could reduce significantly. An Engineer in the audience stated that if you double the Pour Water Pressure the bearing capacity of the pile roughly halves. Clearly permeability in the terraced gravel is considerably greater than the clay.

This issue is even more of a problem because you could conceptually have a Pingo anomaly positioned between site bore holes. This means that you might be unaware of the issue on site until the point the pile is being installed. This is obviously too late in the day simply because by the point piles are being installed the design of the building and its foundations should have been finalised.

As I left the lecture it occurred to me this might make a decent thesis topic for a phase 2 student currently struggling for ideas. It looks like the Geologist lot are working hard to collect data on this issue. Combining this data with a detailed look at the risks a Pingo presents from a civil engineering perspective might prove interesting.

Laurie’s added site product from Phase 2

BP – Hydraulic fracturing hanger

Blog summary

I’ve been at BP for around 7 weeks working in the Projects & Modifications team. Unlike most other Phase 2 attachments, the BP one is slightly different. The overall ‘project’ doesn’t always exist as they are often carried out on a discrete basis, but, like all brownfield offshore engineering, it requires a lot of interface management with the core business of production, and other functional areas of the organisation (reliability and maintenance, wells, inspections etc).

I’ve recently taken up a project which involves the fabrication and installation of a hydraulic fracturing (frac) hanger to connect pipelines during a frac campaign of 4 wells. This is a purely structural project (even though I’m E&M!) but was given to me as it is being fast tracked through the project life cycle to meet an offshore construction date in July. The discrete nature of the project allows for sole ownership under direction from the asset programme manager. The scope is simple but allows exposure to the various stages of the project life cycle in a short time frame, while interfacing between various departments.

Background

The frac hanger is to be installed on to a laydown area of the platform which will allow for interface between the frac vessel and the platform. A 4” co-flexip pipeline is to be lifted in to position using the platform crane and connected into temporary flowlines located on the platform. This interface allows the vessel to pump large volumes of frac fluid down the well to initiate fracture. It will be used for the duration of the frac campaign and removed thereafter. There is not much requirement to chat through the design but I’ve added a picture of the proposed solution and an example of a ‘landed’ co-flexip style pipeline onto a frac hanger. The 3 pins are the interface between the hose and platform. An offshore survey is currently on going to confirm the exact scope of works required, but will probably include a destruct of a side panel and a construct of the frac hanger and new side panel. The hanger is designed to support the worst case scenario, 8.1MTe, of an emergency release of the pipeline from the boat end. Structural assessments have been carried out on the frac hanger and global structure of the platform. These are to be reviewed by a BP structural discipline engineer before approval for construction is granted.

Commercial

The well is co-owned and therefore when something, such as a frac campaign is scheduled, it must have agreement from all parties and will generally be co-funded accordingly. This is unless one party is willing to solely fund the operation to boost the production levels. In this instance, however, this is not what is happening. A third party contractor is funding the whole operation in return for a percentage of the production for a number of years. They are therefore carrying the risk of a non-increase in production (possible), while BP profit from the campaign if this isn’t so. That being said, the actual costs for engineering are fairly straightforward. The frac hanger is being constructed under the Engineering, Procurement and Construction contract that BP have in place with Wood Group (WG). WG will submit an estimate for all aspects required to get the frac hanger in place, BP will pay them while the third party contract will reimburse BP. Simple. I have no appreciation for costs in the construction industry but £250k for what is standard UBs and stock steelwork seems quite a lot.

General offshore construction observations

If you have got this far with reading, well done! I’ll finish off with some general offshore construction observations.

- Offshore construction scheduling is driven by the number of persons on board (POB) on the platform. There is a requirement for a number of ‘core crew’ to continue with production at all times. There is then a float above this for any others that may be working on the platform, with a self-imposed maximum POB (less than the beds available). This is then further constrained by flight frequency to the platform. In order to secure POB the requests must go through levels of authorisation at 12, 6 & 2 week gates, with the risk being accepted by the ‘gatekeeper’. Sort of like Gandalf on the bridge of Khazad-dûm. The ‘bums on seats’ on the flights must be confirmed at the 2 week gate. Below is an example of a platform POB level. In short, everyone requires POB and it is the asset planner’s responsibility to ensure that the correct POB are on the asset at the right time. This often means projects being delayed until areas of lower POB.

- The BP contract with WG is well established and works well. Value for money, probably not, but I’m not sure anything in oil and gas is. When WG are given a SoR they will engineer, procure and construct everything that is required. They have project and asset programme managers who are responsible for the delivery of the project with embedded construction supervisors on the platforms. Most of the onshore positions are also replicated on the BP side too! There appears to therefore be an element of ‘man-marking’ when it comes to the delivery of a project, however, the BP side is acting more as performance managers than project managers. That doesn’t mean you can sack all BP project managers, where they become invaluable is the integration with other functions within the organisation. This is key when ensuring that the project is actually delivered as they are rarely conducted without the help of the platform’s core crew. This is particularly difficult to understand when new to the business as decision rights aren’t always that straight forward.

I’ll look to blog when anything exciting happens, but in the mean time I’ll just explain other works areas I find myself part of.

- Construction of 4 lots of new choke valve pipework. I haven’t actually received the scope yet so nothing more is known than that!

- The appraise/select for the increase of 2 x electric heater capacities to allow 3 gas turbines to be run simultaneously on the platform. This involves selecting the best option based on estimates conducted by Costain and the technical knowledge of the various process, electrical, mechanical etc. engineers.

Your thoughts on blast vibrations.

I know I said I wouldn’t blog again but this is pretty interesting. I am looking at bidding for a contract for an 8 level basement in argillite rock in the centre of Brisbane. This will be the deepest basement ever built in Brisbane is quite ambitious.

I have two problems:

- The site is surrounded by heritage structures and the Riverside Expressway which have vibration limits of 5 mm/s.

Aerial View of Queens Wharf Development

The shiny structure is Queen’s Wharf – you can see why blasting rock may be an issue.

The shiny structure is Queen’s Wharf – you can see why blasting rock may be an issue.

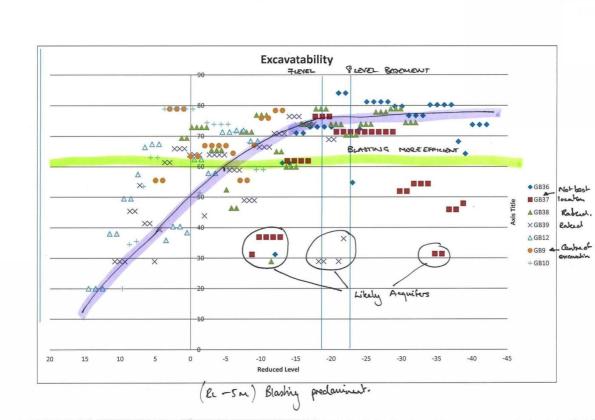

2. I did an excavatability assessment and nearly the whole thing needs blasting.

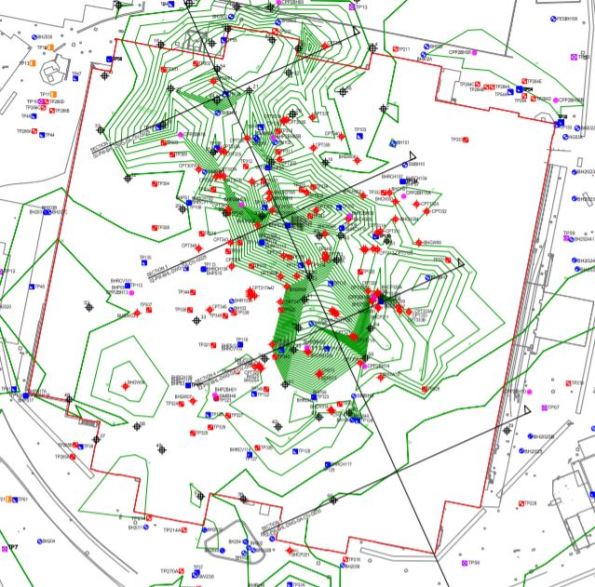

Excavatability Assessement (GSI vertical axis and Reduced Level horizontal axis)

Site map and boreholes GB27-GB35 are missing!

The less permissable vibration the greater the cost (see below). The arguments for the 5mm/s limit come from a german code (the most stringent). I need to produce a paper to argue with ARUP that this vibration limit can be increased. There is about $3 M AUD in savings if I can increase or mitigate the vibrations. Any thoughts?

Some useful background reading.

200281_ Selection of Blasting Limits for Quarries and Civil and Construction