Archive

A flavour of Mace projects in the city

Last week I visited 5 Broadgate which is another Mace site. It is right by Liverpool Street Station and is prime banking territory. UBS is having built a 700,000 sq ft building, based on a single block form, with a gun- metal grey finish. At 12 floors it will include up to four trading floors, each able to accommodate approximately 750 traders, allowing UBS to consolidate its London trading operations into one building.

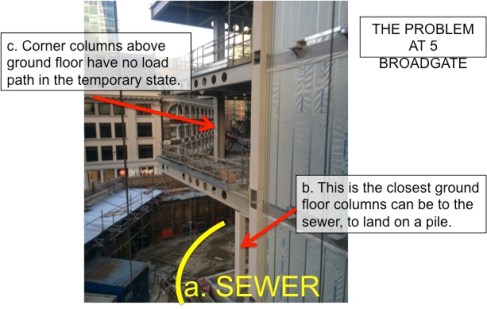

So here is the problem:

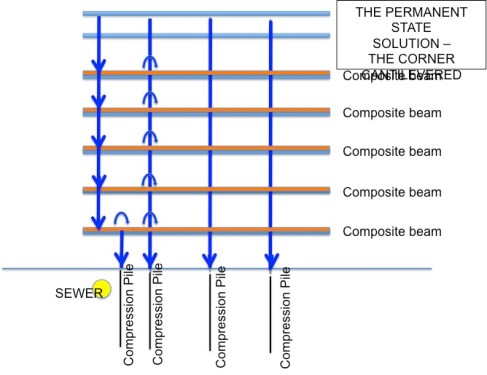

In order to overcome this issue the corner would be hung from a truss on the roof as well as Macalloy hangers on the 1st and 2nd floors.

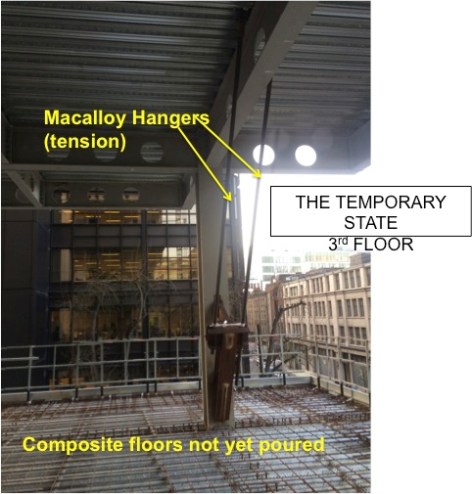

Here is a picture of the 3rd floor with the Macalloys in use

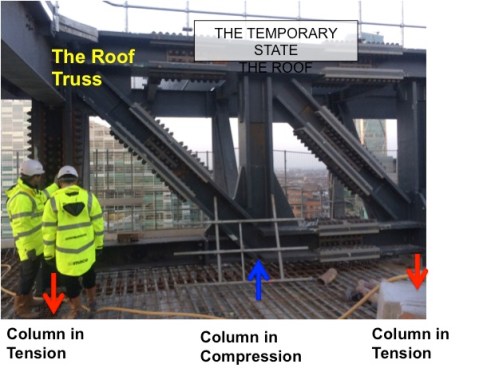

The (big) truss on the roof cantilevers out to allow the perimeter column to hang in tension and suspend the corner. Jacking was used to ensure it had ‘picked up’ the perimeter.

This system seems to have worked well on site. It is reasonably simple to set up and control (with jacking). Mace plan to pour all 11 floors of corner concrete at once so that there is no differential movement between the floors. The Macalloys and roof truss will be ‘stressed’ so that any elastic extension is accounted for with pre camber.

On the South Bank Tower we will also be using Macalloy cables, but ours will be used in the permanent design. The proposed force in them will be 7600kN. Anyone else got any experience with them?

It is a good idea to hit steel to steel connection bolts with a (small) hammer

So here is a picture of Tower Crane Two (TC2). It is a WOLFF tower crane with a 45m tower and a 40m jib.

It was installed on Thursday and Friday last week by HTC. On Thursday morning prior to the installation I went on site with Roy (the Mace Construction Engineer) and the designer (from a consulting engineers) to sign off the grillage.

The steel grillage connects the tower crane to the piled foundations beneath. Simple right? That is what I thought. So we went on site, had a look at it and signed the paperwork after some discussion.

The Grillage

Well on Friday afternoon with the crane built and the load test about to start, the HTC inspector just thought he would check the bolts on the grillage (sprayed yellow in the picture above). Technically doing this was not in his remit, but he thought it wise to give them a tap with a hammer to see if they’d ‘ring’ (tight) or see whether they were loose (and don’t ring).

Well, many didn’t ‘ring’! In fact maybe 5-10 (of 240) were positively loose and perhaps 50% could be tightened further with a long spanner! Queue phone calls to the Construction Manager, Sub Contractors and me! The questions being:

1 Why are the bolts loose?

2. Who tightened the bolts?

3. What torque should they be?

4. Who signed off the grillage?

Since Roy was not in the office I found myself answering these questions. It turns out the answers were:

1. They were not checked, or re-checked.

2. The sub contractor PC Harrington responsible for the grillage sub-contracted the fabrication to DAM Fabricators. DAM didn’t check the bolts.

3. There is no torque. They had to be tight (manufacturers guidelines)! I think this means a man/woman hanging off of a spanner. As I understand it only friction bolts usually need a torque.

4. PC Harrington, Mace Construction Engineer, the Lifting Operation Manager for Mace.

The bolts in question

So what is there to learn? All sub-contractors need to sign off their work (DAM were responsible for the bolts and they had no sign off directly to Mace); Sub-contractors need close supervision (no surprise there); Hit bolts with a hammer to get an idea of how tight they are; And finally understand what checking procedure has been used prior to you checking something.

Have I missed anything???

The key question I haven’t answered to myself is whether we (Mace) should have done a random check of bolt tightness? You chould say yes, but then we’d have a lot of other bolts to check too. I guess it’s all about the risk associated with that particular bolted connection!!!