Archive

Big touble in little….town in the middle of nowhere.

Covers Period 30 April – May 4:

The best week so far at work! Plenty of variety and a chance to get the boots dirty, thus avoiding paper cuts in the office.

EDC SloarWall

At the end of the previous week the contractor had sent me a Risk Assessment (Called an Accident Hazard Analysis AHA over here). Essentially this was pipss poor and far too generic. I bounced it back to them with comments along the lines of ‘take this seriously or I’ll cancel your investigation’. This resulted in them sending ther H&S guy to supervise the task and conduct the relevant briefs and incorporating the issues that I had raised. Even so – our COn-Rep picked their guys up for lack of high-vis clothing, baseball caps under helmets, impropper ise of helmets, not using fall arestors when on the platform. Each of these issues were addressed on site before work continued but it was a constant bug-bear. The contractor has left with a much clearer perspective on the standards that the Corps requires. I have followed this up by sending the chapter and verse out to all parties who are expected to produce the AHA’s. In this respect we demand 100% commitment and complience – or they get 0% work completed at their expense…….I look forward to the inevitable repeat prescription on this.

Have been able to get the tech guys to be less vague about how they intend to deal with the roof ducting – as this overlaps two projects and had not been clearly defined as to where the responsibility on this project ended and the next one began. I was uncomfortable with the initial response as although everyone was happy to carry on working, it left contractual vagueries – and we all love those.

Ashley Reservist Centre.

Issues over defects on a loading ramp have come to a head and I have been giver catre-blanche to go and sort it out. This is going to be the basis for TMR 1 for me as there are opporetunities for technical analysis and research as well as contractual issues to solve. I booked the hotel etc and set off to spend 24 hoursd on site to investigate the defects, interview the contractors and gather evidence.

Breaking down the issues this is a historical birds nest of problems which will take a while to consider and provide appropriate solutions, but the best thing I was able to do was to apply the ‘big levers’ principle as preeched by the Moran and the Farmer. Cutting away all the chaff allows me to find the lever that allows the issue to be resolved and for work to continue. Bottom line solution is that the contractor will undertake spectrographic testing of the placed concrete to prove ifit was up to specification. This then triggers a decision point. If the concrete is up to standard, they recommend and submit remedial actions for us to authorise (at their cost). If it is sub-standard I will work with them to prove the extent of the sub-optimal concrete and the questionable areas will be removed and replaced (at their cost). Simples – but there are a plethora of other issues that also need to be resolved, some of them diplomatically, some of them bluntly. Other issues that need to be resolved are:

– Contractor’s Quality Control procedure has been historically lacking and is still not up to speed.

– USACE Quality assurance procedures are not being followed and need resolution.

– Materials testing documentation is not clear enough to give contractor the level of assurance he needs.

– USACE ConRep is not working cooperatively with the contractor…and vice-versa.

– Deficiency reporting procedure is not working or being applied appropriately.

– Communication on site is inadequate and will continue to cause further delays and disputes.

– Areas of the specification do not comply with the working drawings. Essentially we have 2 song sheets and each party is using whichever suits them best.

From here a quick and dirty report will be produced to get the ball rolling on the resolution. I will then drill into the detail and generate two versions of the findings. One for consumption within USACE and one for the contractor to see. Wrap all of this together and hopefully a TMR will fall out of the other end.

DDSP ECIP Buildings 732 / 760

Used our ninja APMP qualification and skills to review and comment on the proposed PMP for the energy efficiency projects for which I will be Project Engineer.

And in Other News

Enjoyed a site visit to the Mechanicsburg Reservist Centre project which appears to be running on fumes as far as funding goes……they said no blasting as well and look where that got them.

This week’s road kill includes deer, blackbird, hedgehog and possum…although the possum may have been pretending.

We enjoyed our first ever Cinco de Mayo celebrations / Kentucky Derby day. We attended a party where I now see that the theme was meant to be Kentucky Derby (i.e. posh hats and day at the races atire)……I went with the Mexican theme instead. And when we were in the fancy dress shop I saw the coolest Iron-man mask and simply had to have it. So to keep in the theme (or what I thought was the theme) I went as Iron-Man dressed as a mexican (with grigo moustache attached to the mask). In the group photos from the party there is one character that looks decidedly out of place.

Commercials on TV continue to horify me. Apparently your kids can get premature wrinkles. So if you really care about your kid’s future, you owe it to them to treat them with child friendly botox.

Weeks 4 and 5. 23rd April – 4th May 2012

Week 4. 23rd – 27th April 2012

MIST – Minimum Industry Safety Training. Two days of classroom health and safety training in the Oil & Gas Industry is very similar to H&S training in the RSME – lots of PowerPoint and a consultant charging megabucks to teach it! The teaching was actually very good, with the presenter’s experience being passed on through some good anecdotes (crushing injuries, falling injuries) and a video about the Piper Alpha disaster to make us pay attention! Lots of “as an employee, it’s your duty to…” made us realise that it really is up to individuals to make sure that things are being done correctly, and to report it otherwise. They take this very seriously.

BOSIET – Basic Offshore Safety Induction and Emergency Training. Following the MIST, we (my gang of ex-army mates from the MIST course comprising of an ex-sapper, ex-signaller and ex-South African Commando) had another three days of mandatory training before we were licenced to go offshore. This course was a bit more fun though; still lots of PowerPoint but the banter increased as the lead-instruction dropped in quality. Sadly, where we had the experience of an ex-rig worker turned consultant for the MIST training, we now had a little girl who used to volunteer for St John’s Ambulance, and whose experience came from her dad working offshore – and this was reflected in the standard of her lessons (and my Inval). However, the other instructors were great, and before we knew it we were fighting fires and practicing helicopter evacuation from an upside-down, submerged simulator – lots of fun, and great for giving us confidence by practicing what we may need to do in the offshore environment.

Figure 1 – Helicopter Escape Training

Having passed a medical I am now ready to go offshore for a project recce (or similar excuse); can’t wait!

Oh, and my attempts at looking like a civvy are still failing; maybe it’s my chinos, highly polished shoes and pressed shirt that give me away each time?

Week 5. 30th April – 4th May 2012

ETAP CPF ALQ

Well, the ETAP CPF ALQ (or Additional Living Quarters on the Central Processing Facility of the Eastern Trough Area Project platform) is going to Appraise, and I’ve got £150k to spend on appraising it. Easy enough, but tying down the right people to speak to is not so simple – I’ve been stood up once now by the APTL (Area Planning Team Leader, or SO1 ETAP Ops as I like to think of her) who is neither answering her calls, Outlook meeting requests or being at her desk when I pop round to visit; and I really need to speak to her about the business proposal and SOR! Still, no worries just yet, but I’m going to call out the big guns when I get back from The South so I can move forwards.

It’s pretty much as mentioned in the last blog, but with the installation looking to be around the £8-12m mark and the cost of an extra 30 POB being around £5m p.a. in wages alone, (plus increases in flights frequency, risk, evacuation procedures and all manner of other things) I have to get a good business case done to validate whether it’s financially viable or not.

But it’s a really good project to be moving forwards with and I’m genuinely excited about it!

Runcorn

Most of last week I was digging further into the spurious task from one of the Programme Managers, Peter Neilson of investigating where the issues lie (if there are any) between the PSN offices in Runcorn and here in Dyce. This is boiling down to being a question of “what works and what doesn’t?” So far I’ve interviewed a number of members of both BP and PSN staff here in Dyce: the BP members of staff find the engineers in Runcorn much better than the Dyce ones here, with the problems lying in PSN’s Cost Estimating and variation control mechanisms, that is, tying down the initial spec of a project at each stage before; the PSN Cost Engineer I spoke to says that everything is rosy. Funny that.

Tomorrow (Tues 8th May) I fly to The South (Manchester) to interview a number of Job Responsible Engineers (JREs – PSN’s title for Project Managers), Programme Managers and Delivery Focal Points to see what their views are in some closed-door interviews. Having spoken to a JRE on the phone already, I expect that they are all ‘in the dark’ on what the delays are from, and as frustrated as the BP staff are, but I guess we shall see… Then, on Wednesday (as I found out this morning), I get to present my findings! This will be in an open forum manner to those in Runcorn I’ve interviewed, plus Peter and a few other Programme managers from here. The aim of this will be to see if there is a ‘best way forward’ if anything does need to change.

So, here’s to hoping for some constructive criticism from the interviewees so that this can form the basis of a managerial TMR!

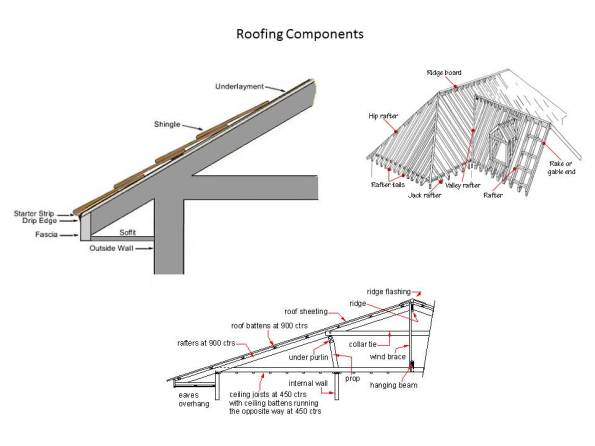

Roofing Components – Learning To Speak Builder

Have spent much of the day trying to understand what the hell my mech sub-contractor is on about. He has been telling me where he’s going to put his screws (not as funny as it sounds), but it seems all builders speak Klingon. I didn’t know half of these words so have made myself a translation slide – though you guys might find it useful if you ever need to sort a purlin from a rafter, or if, like me, you don’t believe that underlayment is really a word.

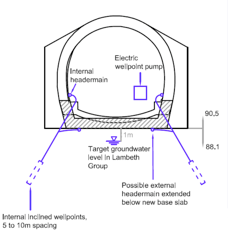

Arial Drainage – Anyone?

Has anyone ever come across ariel drainage? I haven’t been able to find anything on it from my own cursory research. I’d like to know a little about it because the hydraulic consultant on my site is telling me that it is because he has employed an ariel drainage strategy that the soil stacks and vents don’t line up. This is a man who I’ve caught out telling me porkies a few times already so I’d like to know my onions before I challenge him about it. I had understood that it was standard practice to have a soil stack that rose from the sewer in the ground slab through all floors to the roof where it vents, and that the drains at each floor run into it. I know that sometimes the stack has to make a slight detour, because drainage falls below mechanical services and structural elements in the priority of change, but thought that any deviations would be minimal and with a big radius. The deviations I’m talking about use 90deg bends and are across many meters on a single floor.

The job I am working on is a little unusual, in that there is no services riser. The section of the hospital that we are currently re-fitting was originally built as a single story, and then converted to a double, then a triple storey affair. Things seem almost to have been piled up on top of each other as the various re-fits and expansions have taken place over the years – even the structural columns have moved around (Mark, this probably answers your earlier question about the location of the med gas isolation valves – As is happening with this referb, they seem to be thrown in wherever they are needed to allow the next extension to be built). Here is a drawing of the new drainage system in my referb area, with my annotations of where the soil stacks are located on the floor below. The stacks and vents are linked by a vent header system in the ceiling above the floor shown.

Do you think that the use of air admittance valves on top of the stacks might be a more economical arrangement than using the vent headers?

Engineer..?

Period Covered 23 April – 4 May 12

Summary: Engineer…?

My responsibilities have grown considerably over the last 2 weeks as my role has shifted away from supervising to being a project engineer. This has happened rapidly and I have to balance my on site work with office based work. Efficient time management and communication has been essential as I have also been away from site for 4 days (AER writing, ANZAC Day and 2 days on a Safety Course.)

Also during this period the weather has shifted and the rains have begun. This has caused considerable disruption and as foreseen in my last blog it will be the simple/stupid errors that threaten the job and not the complicated technical aspects.

During this period I have completed the following:

- Supervision of GMF ground work contractors – bulk & detailed excavation and pile cropping

- Technical Anaylsis and plan for project dewatering, including brief to client. (Support from John M really appreciated)

- Dewatering Tender Analysis and award of $700,000 of dewatering work. (13 deep excavations and 180 pile caps)

- Dewatering Activity Method Statement written

- Given responsibility for approx. $3 million of Post Tensioning work. I will be responsible from writing the scope and schedule of work through the whole of the tender process to implementation on site.

- Completed TRA and Hazard Inspection audit

- Attended 2 day Safety Risk Leadership Course

- Safety Supervision

- Programme co-ordination meetings

Work on site. Exciting times on site as the Northern end of the service tunnel has begun to look like a tunnel with the blockwork wall being constructed and the formwork for the roof slab in place ready for a pour this week. Work on the remaining sections of the tunnel continues but the arrival of the rain has caused disruption (lost time, unable to waterproof in the wet and the problems with Syphon A, see below).

The remainder of the site continues its steady progression with the site opening up as the bulk excavations continue and piling the final portions of the retaining system has begun.

Finally, worthy of note is that work to divert a high pressure gas main in the North East Corner of site is due to occur on Monday. Once complete this will enable the completion of the logistics sliplane and provide a drive in/drive out solution to material deliveries. This work has been delayed for 3 months whilst the Client and Power company come to an agreement!!

Issues/observations. Water Water Everywhere:

With torrential rain arriving in Perth it has caused considerable problems for the Southern End of the Service tunnel.

The first bout of rain arrived overnight last Saturday and resulted in the collapse of an excavation. This was dramatic enough but was made worse as it covered the final portion of the service tunnel that had not had its slab poured. The collapse caused a 10m x 10m area containing the already the set out reinforcement ready for a pour on the Monday to be covered in sand. This took 3 days to clear as the reinforcement was stripped back and various “honeysuckers” were employed to clear the sand away from the mesh.

This meant by Thursday parity was reached. Just in time for another morning of torrential rain on Friday. What was first suspected as just bad luck (no one was on site to see the first collapse), turned out to actually be a simple mistake by the project.

In order to connect the hospital to the storm water system (run South to North) a serious of symphonic drains (connected chambers) are required to store water and divert it under the major energy services will run ( they run East to West). The syphons had not been fully constructed (not an issue in the dry) and the project had forgotten/not thought about capping the inflow from the rest of the surrounding area’s stormwater system.

As a result a “water flume” began pouring out of the unconnected syphon and flooding Area A again!!! After much wading around and “playing” with small grindex type pumps we lost the battle! A more permanent solution has been devised we plan to construct a sump where the stormwater enter site and a gilkes pump to pump water from the sump past the offending unbuilt symphonic drainage system and into the existing stormwater system.

Storyboard to Show Area A Problem

Further Work

- Continue with dewatering plan. Liaison with contractor, co-ordination with contract administrators and sub contractor to ensure delivery on site.

- Post tensioning work. Write tender plan and schedules in order to brief management on Wednesday and begin the tender bid process.

- Prepare for CI’s Visit.

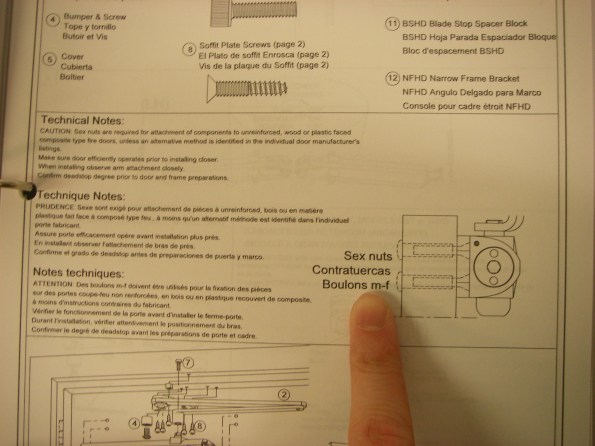

It’s not essential, but i am intrigued…

I found an interesting term within some of the Fire systems literature that i have been reading – see photo.

I tried “Googling” it to find out what it was, but had no joy, but had no success…

What do you think?! I had to ask everyone round the office is they knew what one was.

I think Chris W might be the best person to advise.

Contracting, Sub-Contracting, Re-structure & Conflict Resolution!

Contracting

Re-profiling & Sump Installation. Re-profiling works has continued and the installation of temporary sumps within the tunnel, as well as localized temporary measures to divert the water have been sufficient to enable a -45mm tolerance, set by the Designer to be achieved. The profile of the existing tunnel allowed for 300mm (West) and 800mm (East) of slab and brickwork to be excavated to the final Structural Slab Level (SSL) at the sump locations. This step change was sufficient to create a natural shallow sump and negated the requirement to install addition temporary infrastructure that would impede access and have to be stripped out. Manual setting out and checking levels remains relatively time consuming but has proved the most flexible and effective method. The Client is remitted to check levels in accordance with the Inspection & Test Plan, which we invite them to witness following an EDM survey. The re-profiling has however uncovered significant longitudinal cracks which as well as severely increasing the flow of water into the tunnel, are of some concern to the Designer, who has been on site to carry out inspections.

Re-profiling at the entrance to the West Single Tunnel.

Re-profiling at the entrance to the West Single Tunnel.

Re-profiling at the base of the East Approach Ramps.

Re-profiling at the base of the East Approach Ramps.

Re-profiled section to create natural sump.

Re-profiled section to create natural sump.

Temporary ‘Temporary Services’. As a result of a 10 week delay in the Temporary Services Contractor commencing on site, it has fallen to Vinci to provide the requisite enabling services within the tunnel and approach ramps, including drainage, lighting, and ventilation. This has proved an extremely costly exercise, both in terms of manpower and resources. The drainage system, at any one time, comprises a minimum of 2 x 6” and 2 x 4” pumps operating constantly, pumping up to 1000m3 water a total of 1 km, over 15 m head every day. I estimated the size of pumps and pipe work based on the predicted seepage from re-profiling in the river terrace deposits (above the clay layer), and a contingency for rain. I also made the (in hind sight optimistic) assumption that the Temporary Services sub-contractors would gain Client ‘Acceptance’ to start within a couple of weeks from the Vinci installation. Upon reflection: despite the uncharacteristic hot weather in March, it is the UK – it rains A LOT; seepage is unpredictable and despite similar geology, the seepage encountered in the West side of the tunnel is considerably more than the East, and, Client ‘Acceptance’ is not a viable planning tool! Fortunately nothing that a simple change of pump and 300m of pipe work couldn’t solve – it pays to stay in with the site workforce!

Temporary sump and drainage in West Single Tunnel.

Temporary sump and drainage in West Single Tunnel.

Now that the central pump house has been turned off in preparation for shaft deepening and the Dock discharge consent has expired. All construction water within the tunnel must be diverted into sewers on the East and West surface sites. The Thames Water consultant carries out random checks in order to check that the quality and quantity of water being discharged is in compliance with the consent. Re-profiling is 70% complete on the West and the discharge is currently 676 m3 (176m3 over the consent) and 363 m3 (337 m3 under the consent) with 60% re-profiling remaining. To further compound the issue, the Temporary Services design allows for construction water to be provided by the fire main, which will generate additional construction water discharge. Potentially an extremely costly aspect of the project, not accounted for at tender. Whilst the foremen have ‘solutions’ for reducing the flow rate readings, the ‘legal’ alternative is to apply for an additional consent (which will take weeks if granted). Dependant on the outcome of the Thames Water consultants report, the Contractor may raise an Early Warning Notice, which the Client may accept or dispute as ‘foreseeable and/or within Vinci’s scope’.

Tunnel water discharge into Thames sewer.

Tunnel water discharge into Thames sewer.

Tunnel Health & Safety. In addition to the control of water, the progression of re-profiling into the tunnel required the implementation of several additional H&S measures such as control of dust, noise, fumes, and gas levels. Dust suppression, additional ventilation, and heightened levels of PPE were put in place. However, high levels of Nitrogen Monoxide, as well as the ignition of a methane flame as a result of excavating the tunnel floor, have since stopped works. We carried out a full monitoring investigation, and a tunnel gas consultant has been called into offer advice regarding intrusive works, before re-profiling works will continue. I am in the process of updating the ‘Tunnel Access, Egress and Emergency Procedure’ in order to improve it’s relevance and practical application given the changing nature of works and services within the tunnel. In fact, I thought ‘The Practical Application of H&S within Tunnels in the Construction Industry’ might make a relevant H&S TMR (and of course kill two birds with one stone, or at least kill one and make the other one ill through gas exposure?!)

Re-profiling within the Single Tunnel.

Re-profiling within the Single Tunnel.

Current temporary ventilation configuration: positive airflow in from the ventilation shaft and out the West portal.

Current temporary ventilation configuration: positive airflow in from the ventilation shaft and out the West portal.

Re-Structure

Commercial. Currently the Vinci bill for plant on site, of which 30% is providing temporary ‘Temporary Services’, is £35k per week. How much of that cost Vinci can recoup from the Client (for prolonged ‘Acceptance’ times or unreasonable rejections of submissions), or from the sub-contractor (for sub-standard submissions or delayed start times) now sits with the Commercial Team. A recent 50% increase in Quantity Surveyors, may be a reflection of the Contractors current predicament. For example, since the start of the Project Crossrail has raised 63 NCEs, and Vinci has responded to 30. Early Warning Notices are also a common occurrence.

Project Team. In addition to the uplift of QSs, several additional positions have been created across the Project Team. Namely, an additional Construction Manager (there is now one for Surface Rail and one for the Tunnel and Central Section), an Engineering Manager (to deal with design issues, which have thus far caused significant delays, and future interface management between sub-contractors and the Client), a Materials Compliance Engineer (to deal with the ‘Acceptance’ of materials, currently a disproportionately time consuming component of a Section Engineer role), a additional QA Advisor, and 3 more Section Engineers. The reasons for the sudden uplift were not disclosed, however I suspect the following are significant factors: the full scope of the Project was underestimated; insufficient contingency for problems encountered on site (although arguably the piling sub-contractors who are on their 5th iteration of site team have probably exceeded any reasonable assumption); and underestimating the strict procedural nature and commercial advantage of the Client. Whatever the reasons, the realization by Project Management that Vinci needs to meet the demands and standards on site, reduce Client ‘Acceptance’ timelines, but also have the capacity to achieve an equal commercial footing, is a positive and welcome move.

Sub-Contracting

VVB. Only 10 weeks on from their original start date, the Temporary Services sub-contractor has finally started on site! However, the site is still awaiting Mains Power (delayed by 3 weeks) to be turned on at the central compound in order to feed the tunnel via the ventilation shaft. The biggest contractual error: Vinci not delegating responsibility for access to VVB. In an attempt to provide mobile access within the tunnel, a ‘mobile’ platform was designed and procured by Vinci. Unfortunately, the mobility of the platform was subject to a lengthy re-configuration process each time a move was required. Since Vinci would inevitably be charged for the ‘standing time’ during this configuration, it was deemed unfit for purpose.

The proposed mobile access platform provided by Vinci

The proposed mobile access platform provided by Vinci

Vinci are now remitted to provide a MEWP to VVB for all access requirements, including fixing brackets at 3m intervals along the length of the tunnel. Access scaffolding through the ventilation shaft and into the tunnel, has now been subcontracted back to VVB and Vinci are awaiting a design, which will then require Client ‘Acceptance’ before work can proceed. Another additional plant hire cost, and significant delays incurred by the omission of one line from a sub-contract.

VVB installing LV cables from mains supply to distribution board in tunnel.

VVB installing LV cables from mains supply to distribution board in tunnel.

On a positive note, I attended the ‘Hilti’ Installation and Testing Course and am now qualified to test the installation of services brackets as part of the Inspection & Test Plan. On a not so positive note, if the Eastend residents don’t stop steeling VVB’s cable, there will be no power cables to install on the fully fledged and tested brackets! Another contractual debate: who is responsible for the security of sub-contractors equipment (in storage and once installed)? The VVB director is currently pushing for the installation to be handed over in sections in order to shift the risk to the contractor, which Vinci is resisting. The contractor is arguing that it is deemed a ‘secure site’ and that the security guard contacted the police, VVB have a lockable container, and that they could order materials to site in accordance with their programme and not stockpile. Police and insurance report are being generated, and I will disclose the results of the theft and sectional handover commercial battles in my next Blog!!

VVB installing LV and lighting brackets.

VVB installing LV and lighting brackets.

Bachy Soletranche. Only 1 week behind schedule, the Drilling & Grouting sub-contractors have mobilized and started on site today. Contractually, unlike VVB, they were tasked to provide all enabling equipment, and whilst initially I could not see the logic behind them bringing in generators, when there ‘would’ have been mains supply, I can now see why Contractors want to shift all possible responsibility for enabling works onto sub-contractors. The unforeseen delay in mains supply connection would have been billed as standing time to Vinci, or Vinci would have had to hire generators, (for which noise consent requires 4 weeks) resulting in further delays.

Extent of TaM grouting within the Twin & Single Tunnel (pink extent lines mark sump locations).

Extent of TaM grouting within the Twin & Single Tunnel (pink extent lines mark sump locations).

Vinci were however, responsible for providing a Working Platform for the Drilling Rig. The platform had to meet the requirements of the Bachy ‘Working Platform Certificate’ specification, as well as gain Client ‘Acceptance’ as a Temporary Works Design. By using the ‘arisings’ (I did question if this was actually a word, but was duly informed that it is an engineering term meaning material resulting from an operation) from the re-profiling, the requirement to ‘muck away’ the arisings was negated, as was the expense of procuring new material. By sending a sample away for a Particle Distribution Test, we were able to prove to the Client that it was of a suitably well-graded nature (characteristically akin to the Crossrail approved 6F2 fill material), to compact and use as the platform. The drainage diversion scheme correctly assumed no seepage (and thus flow of water) would occur between sump locations, and, that all water would be pumped out from the existing central drainage system prior to the pump house being closed. The later part of the assumption has however, not proved to be correct, and residual water from the existing drainage system is seeping back into the central section, thus slowly saturating fill in the centre of the twin tunnels. Whilst the steel lined central section does not form part of the platform, remediation works will be required to retain access.

Platform laid and compacted from re-profiling arisings to create Bachy Drilling Rig.

Platform laid and compacted from re-profiling arisings to create Bachy Drilling Rig.

A further consideration, which fortunately for Vinci was in the sub-contract, is that Bachy are responsible for recycling their own water, which will be fed down the ventilation shaft from the central compound. Both the contracts manager and the foreman came on a recce to the site and were made aware of the sump locations. However, it now transpires that no plans were put in place to divert water to these sumps. Bachy contingency planning is now taking place, which may involve guttering along the ledge or a trench within the platform.

Drilling and TaM Grouting control panel.

Drilling and TaM Grouting control panel.

The rig platform had to be extended in order to accommodate the fact the control panel is on the left hand side and thus the rig can only operate in one direction. Another example of additional work that could be avoided by attention to detail and early contractor – sub-contractor engagement and planning. Something that is often victim to disproportional resource allocation to gaining Client ‘Acceptance’.

The 10 week Drilling & Grouting operation will be a ‘Red Zone’ in accordance with the ‘Tunnel Access, Egress and Emergency Procedure’, requiring heightened H&S measures and alternative emergency procedures due the generation of noise, fumes, COSHH material and the restriction of access.

Subcontractor Delay. The delay in subcontractor start dates can be attributed to a number of reasons, however I believe the principal reason in both these cases is cross over between Temporary Works and Permanent Works. The contractor submits what is believed to be a design, which meets the scope and fulfills the submission requirements of a temporary design and installation. The Client on the other hand is concerned with, and focuses considerable attention on elements that will be handed over, or incorporated into the final design. In the case of the Drilling & Grouting, the issue if further compacted by the tunnel structural engineers wanting specific pressures for loading modeling and analysis, from a methodology based on a non-exact science. A Client, Contractor and Bachy Designer meeting was held which clarified most of the Clients concerns, and an agreement made that will see additional monitoring measures implemented in order to provide the Client with the requisite in-situ information during operations. A reasonable request, given the risk associated with grouting, but again not factored in at tender, thus affecting planned construction scheduling.

So What & What Next?

Future Planned (& Not So Planned Work). Just when things seem to be coming together, issues being resolved and subcontractors starting work. More sub-contractors come along….. and they all want to work in the tunnel! A result of delayed start dates, and lack of forward planning, communication or additional Project Manager’s Instructions has resulted in the following scheduled to take place within the Twin Tunnel during the next 8 weeks, starting on Thursday….. over to the Section Engineer!:

- Livis The Client has requested a number of additional cores to be taken throughout the structure, including the Approach Ramps, the Pump House and the Twin Tunnel Section in order to ascertain further information as to the structure composition for the final design.

Coring subcontractor Livis taking cores on the Approach Ramps.

Coring subcontractor Livis taking cores on the Approach Ramps.

Cores from the pump house required to confirm pump house reconstruction design.

Cores from the pump house required to confirm pump house reconstruction design.

Cores required through base slab within steel lined twin tunnels.

Cores required through base slab within steel lined twin tunnels.

- WJ Groundwater. In addition to the global surface Thanet Sand and Chalk dewatering wells within the central compound, WJ are contracted to install localized inclined wells within the Twin Tunnel, in preparation for invert replacement (currently scheduled for June!), and the installation of the cofferdam in 2013.

Planned installation of dewatering wells within Twin Tunnel.

Planned installation of dewatering wells within Twin Tunnel.

Geology at the central section of Tunnel (clear purple represents the Docks and surrounding brickwork, and grey shafts the ventilation shafts, marking the extent of the Twin Tunnel).

Geology at the central section of Tunnel (clear purple represents the Docks and surrounding brickwork, and grey shafts the ventilation shafts, marking the extent of the Twin Tunnel).

Evolving Role of the Section Engineer. Already my responsibilities have shifted from focusing on gaining sub-contractor ‘Acceptance’ and mobilization, to monitoring, Quality Control and co-ordination on site. I remain responsible for Vinci works and enabling works, and after a few heated discussions with the Foreman and Works Manager, now appreciate that even if a project is driven by sub-contracts, the contactor (of the old school variety) will always resent someone else doing the work that the contractor used to do in the good ol’ days! However, I have also witnessed the sub-contractor take advantage of this situation, and winding the contractor up even more! I also appreciate the frustration on site at the apparent lack of planning (often resulting from inadvertent delays, other times they may have a point). All of which generally results in the Engineers getting stuck in the middle – something that the Project Director picked up on, (whilst standing in for the Project Manager) and called a conflict resolution meeting with our team and the Vinci site management team. It transpired that the Foreman and Works Managers were in fact frustrated with much bigger issues, aimed at higher management levels and mostly regarding surface works. A relief for our team, but from a personal perspective, I was reassured that a member of the management had acknowledged the fact that there were issues within the Project Team as a whole.

From a Section Engineer’s perspective, I can see both sides, and will continue to try and tip the balance between reactionary vs. planned operations. However, as you can see by the ‘Future Planned (& Not So Planned) Works’ above, this is not always possible, and hence the role of reactionary planner, politician, diplomat and ‘defender of the peace’ must also come into play!

Civify Tip:

Military words which do not exist in civvie street: ‘De-conflict’! I have felt the need to use this word a lot over the last few days, but was duly informed by my Production Manager that apparently it does not exist?! After explaining what it meant, the term ‘Interface Management’ was suggested as a more suitable alternative! Fortunately, I had not yet used the term in front of the Client, who instructed that the word ‘de-construct’ be removed from a Method Statement with regard the dismantling of the Pump House, for fear of destructive connotations!! (We did have to point out to them that this was the word used on the original instruction!).

JSP 101

Does anyone have the Word template for JSP 101 that I can install? I’m sick of trying to wrestle with Bill Gates about this paragraph alignment!

Is there a link I can download it from?

McFry

PS – The motor Vehicle Authority boils my piss!

Capt C M Warner MEng MInstRE AMIMechE RE

Weel done to everyone in the Corps – we are clearly all engineers!! I paste…

The Institution Royal Engineers is the oldest of the Corps organisations and originally served only the officer cohort. As a member of the Engineering Council it is the only military institution recognised as being of EC standard. The Institution RE is authorised to register Engineering Technician, Incorporated Engineer and Chartered Engineer.

With effect from 1st May 2012, all serving members of the Royal Engineers will automatically become members of the Institution of Royal Engineers. Those in Sapper rank will be classed as Apprentice Technicians. The remainder of the Corps will become full members of the Institution RE and are authorised to use the post-nominal MInstRE. For those already holding Fellowships, FInstRE may continue to be used. No action is required by those serving in the Corps. A full briefing note will be disseminated in due course outlining web details and associated services. Until that time, could I ask the chain of command to brief this detail to all soldiers under command, emphasising that this is an historic moment in Corps history as we are now [CGS] for the first time ‘All of One Company’.

Colonel Seán P F Harris, Colonel Royal Engineers, Headquarters Royal Engineers, Ravelin Building, Brompton Barracks, CHATHAM, ME4 4UG.

Email: Dii EinC(A)-RHQRE-RegtCol, regtcol@rhqre.co.uk Mil: 94661 2227 Civ: 01634-822227. Mobile: 077716 77397