4/5th PWRI Flowline Update

So…… it’s been a while since my last blog, for two main reasons. First, priorities and second, any blog would be a cut a paste of my last blog, since the same issues with material and ops support have been a recurring theme. That being said, I thought it was time for an update;

Situation

The 4th & 5th PWRI flowline is coming towards the commissioning phase but there are still issues cropping up. The materials are all sorted, although Ops Sp issues remain, and will always be an issue. I have summarised further problems below;

Power Tie in

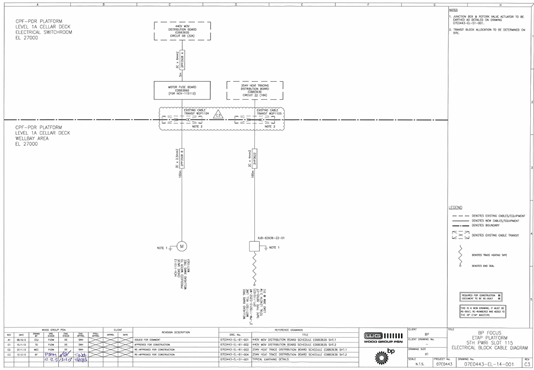

The diagram below shows the extent of the electrical work that has been carried out.

As you can see a fairly simple scope, with just trace heating and the choke Motor Operated Valve (MOV) to be tied into their respective DBs. Unfortunately when the elec techs went to tie these into the DBs, it was identified by the platform that the cabinet could not be isolated as it removed the ability to remote operate the rest of the choke valves. The following options were considered for the MOV tie in;

- Isolate the DB and have an inst tech with a radio standing next to the choke valves in order to manually operate as required. A risky option as control would be minimal and delayed. This was not considered further.

- Tie into alternative DB. Nearest DB is some distance away and it is unsure what it currently powers. More material would be required, a workpack change would be required and an investigation would be required to understand what it powers. Not considered further.

- Do nothing and wait for the next outage. This would have significant cost implications, since the rate of PWRI is limiting hydrocarbon production and is relying on the 4th and 5th in order to increase. Not considered further.

- Do nothing, but run flowlines in manual, and trim using PWRI flowlines 1,2 & 3. MLCOA.

Decision. Option 4 was chosen as the MLCOA, but requires buy in from everyone involved. It will be necessary to carry an A(Qualified) ‘punch list’ item through System Handover (SH-1), which is not really the norm and makes people twitchy, as it has been known for punch list items to be forgotten about. It also required a growth request to be submitted to get the extra work into the outage in Apr, which is already over booked.

The same issue exists with the trace heating, but an alternative DB has been identified as a temporary solution, until permanent tie in during the outage.

Instrumentation wiring modifications.

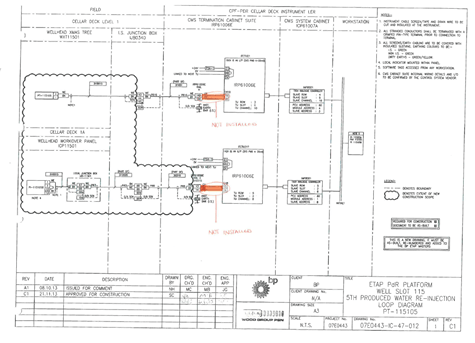

18 months ago, ABB carried out modifications for this project, specifically software upgrades and patch wiring modifications in order to get the instrumentation signals from the transmitters to the control room. Two weeks ago, we went into the cabinets to terminate the instrument wiring to find that the modifications had not been completed. See below.

As you can imagine, there were a few phone calls and finger pointing from both sides, but essentially they hadn’t completed all what there were supposed to have done. That then turned into 2 weeks of us trying to get them to commit to dates and availability, but them not doing anything until a PO had been raised to pay them, which takes time to generate and required ABB input, which they were also dragging their heels about. Of course the discussion about why we are paying them again to do something they should have done is a different discussion. We now have someone offshore to complete the mods.

Literally as I type, I have just received an email which states that the mods required would have to be done in a shut down due to the other wiring in the cabinet. This is significant, as the chances of commissioning and putting into service the flowlines now is almost certainly impossible and will have a financial cost of c. $100k a day in deferred production.

Of course there will have to be an investigation as to why the work wasn’t carried out in the first place, I’ll let you know the outcome.

Pipe support clash with Line of Sight gas detector

A few weeks ago it was identified that there was a clash between a pipe support spring can and existing pipework which is part of the deluge system. This required a re-design of the pipe support and was moved 90mm to avoid the clash. Shortly after, it was identified that it now clashes with a LoS detector system which picks up gas leaks in the well bay, which is quite important.

It has been painful, but there is now a way forward by moving very slightly the LoS detector. This took a week to resolve and discussions with a whole host of people to get acceptance which didn’t require a separate Management of Change (MOC) procedure.

Summary

This project continues to throw up issues, which take a significant amount of time to resolve. There are of course a few questions that need to be asked;

– Why was the ABB work not completed as thought?

– Why has it only been identified now that the DB and cabinets can only be worked on during an outage

– How was a piping clash not identified in the design phase?

I will keep you posted, as the significant cost implication will cause a fair bit of noise.

Time spent on recce…

Thanks Rich for a very interesting comment! however, you do make a good point.

WRT the LoS clash – The project was designed two years ago and looking at the picture would seem to be fairly new and I assume was put in after the flowline was designed. The same may be said about the deluge system as it is a new well and may not previously have been there.

What should have happened is a question 4 moment. That being said, the project has been handed over so many times between project managers, that the detail has got lost in the background noise.

WRT the DB tie in. This is simply down to a difference of opinion. One shift said yes, the next said no, and this is something we are constantly up against.

WRT the ABB wiring mods. ABB sub contract the work to NForce, but get checked by an ABB engineer; it now seems that we need to check the checker. This is a concern that work got missed, and is part of a wider issue with ABB and a concern they cant handle the amount of work we need them to do.

Interesting comments, but diagrams difficult to follow.