NLE – Battersea Station

Last time I spoke about the project in general so here is a bit on the detail of the project, specifically the Battersea site of the NLE (Northern Line Extension).

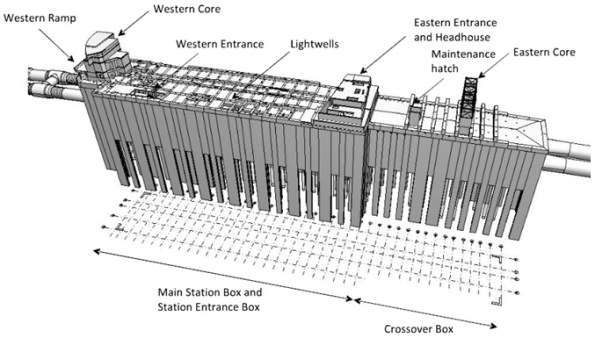

Station and Crossover Boxes

The whole Battersea site simply splits into two boxes. The Station Box is the bigger of the two and is where the majority of the station is going to be situated. The crossover Box is smaller (about a third in length) but still as deep. This box is simply allows the trains to cross from one side of line to the other before it pulls into the station. The Crossover Box is also the launch and access box from where the TBMs will be dropped down and also act as the area to dig out the launch tunnels.

The design for this is essentially Ex Cofferdam on a much bigger scale, just replace sheet pile walls with Diaphragm Walls. Although the D-walls themselves are being constructed inside a 5m sheet pile wall secondary cofferdam. The D-walls vary in panel width (2.6m to 4m) by 1.2m and are saw toothed (see picture), essentially because the shorter ones are as deep as the bottom slab and the longer panels which are 60m long are mostly end bearing onto the layer of Thanet Sands. More on the Thanet Sands another time.

Tunnels

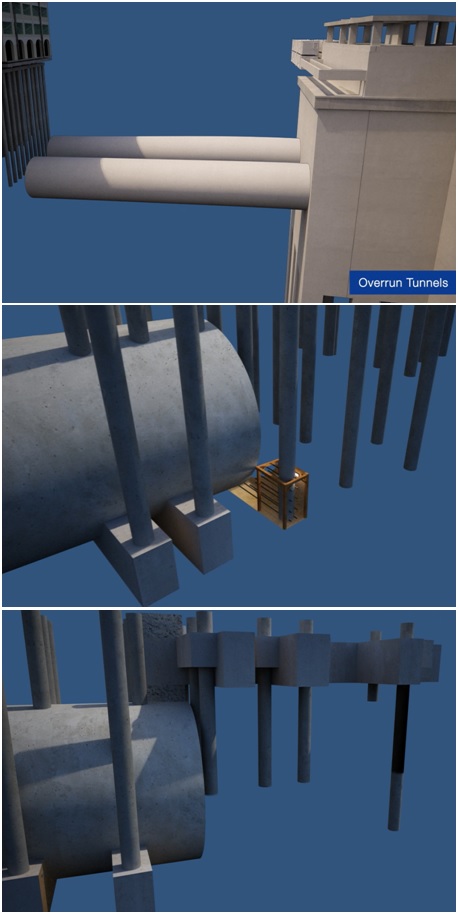

The tunnels are relatively self explanatory except for the bits that won’t be done by TBM. The first 200m on the East side (TBM launch tunnels) and about 200m of over-run tunnel on the West side will be dug manually (well mechanically but not by TBM) and then spray lined with concrete. The over-run tunnels are quite interesting as these are apparently part of TfLs plan to secure a future extension to Clapham Junction (no present funding available). These overrun tunnels will go through the pile foundations that the Battersea Cats and Dogs home.

There is cunning plan to dig up to the piles and prop around them/ tie them together in a move that the NLE Construction Manager admitted to me “will most likely break all the windows in the building”. Though they did get a massive extension that triples their space to keep them happy. The following pictures are a bit of that sequence from a video that shows the process.

Muck Conveyor

Finally worth mentioning the much conveyor which has been installed to allow muck to be carried away by barge. From a cost point of view it the £16 per tonne compared to around £300 per tonne by road seems an easy decision but when you factor in the £5 million initial cost and maintenance of the conveyor over the length of the project it nearly breaks even. But it does save hundreds of road moves through London which goes a long way to reduce carbon emissions and keep the locals happy. At present the conveyor is loaded from a muck bin and we are moving about 1000t a day. Eventually the conveyor will extend to the bottom of the crossover box and will connect directly to the back end of the TBM running 24/7 (about 4 barges a day).

The project to date

As we speak, Cementation Skanska (principle sub-contractor) are about 2 weeks away from finishing D-wall construction in the crossover box along with a few weeks of rotary bored piles in the centre (1.8m to 2.4m in diameter). Cementation Skanska are very much on the critical path and will be handing over parts of the box to us (FLo). So where as so far the pressure and risk is somewhat on Skanska it will soon shift to us to prep the crossover box for the TBMs. As I have quickly learnt, anything linked to the TBMs are pretty much on the critical path.

Groovy way of dealing with a piled foundation thorugh the middle of the job. As far as I can see from your models; the end bearing capacity on the piles on the edge of the tunnel line seems to be being augmented using an enlarged base foundation adjacent to the tunnel line. The really interesting one is the centre pile. It is being cut. Either:

a) it remains as a load to be taken in hoop stress in the tunnel lining OR

b) it is intended that the superstructure redundancy permits re-routing of the load to the adjacent piles OR

c) a bit of both

In any event I agree that there will be deformation in the superstructure. I’d guess that there must be some form of observational method being applied to the the Dogs’ Home

I wonder if they would have considered this approach had most of the residents affected not been feline\canine?

Jonny, interesting aspects which are all directly comparable to methods of working on the Tideway project. Barges and conveyors meeting the ‘all by river’ principle. What it a client requirement for barges? How is it working out – tide levels causing issues? Do you have camp sheds for the barges- if so please can you send a photo.

TBM versus SCL.

Did the contractor push for the SCL solution? The issue is ground movements with SCL are much greater than with the TBM. I think the balance comes down to time (and cost) rather than quality (as in dogs losing their windows for a while).

Why are the start and ends of the drive start point being done by SCL, why could the forward section not be done by TBM? Even if it takes a bit longer to build the TBM into the ground surely savings in reduced SCL costs and damage associated costs for deflections?

Is the plan to carry on through the piles in the future? Do you expect to have to remove reinforcement in the piles or does that finish higher than the toe levels? What are the piles /tunnel founded in (London clay or are you lower)?

John, It’s a bit of both actually as you mentioned. The raft above the section of the tunnel is supposed to hold the piles and distribute the pile loads more evenly. I have to admit though that understanding of this part of the project is pretty limited in the office right now. The tunnels team are still not onsite and will take over that part from Summer.

The deformation is pretty well accepted almost as a fact of life hence for the massive free extension that the home got to the north. The tunnel is all in London Clay.

Damo, the barges were a TfL initiative all part of reducing traffic and reducing carbon emissions. Tides are an issue at present as the jetty has not been used in many years so following hydrographical survey that we had conducted barges are not able to rest on the bottom (protruding objects and bed profile). That means we can only load during high tide or if we start earlier then we have to stop during low water. This week I have been writing a scope of works to get the jetty ‘dredged’ and cleared which will allow 24/7 loading.

The term ‘dredged’ is a delicate topic as obstacle clearance (which may include riverbed profiling) is easy to do however dredging requires all manner of permits and licences. In any case the PLA (Port of London Authority) will only allow the barges to track through London at high tide. a) so that they are against the tide and are slower and therefore have more control and b) to ensure enough draft under some of the bridges.

Tunnelling,

The drivers were for SCL were a speed and flexibility. The costs are high (up to 97% wastage in concrete) but nothing compared to the cost of TBM operation. SCL worked well on Crossrail at Tottenham Ct and Bond St so the contractor (FLo) felt confident it would work. Settlement is not really an issue. Cats and Dogs home was mitigated (not sure about network rail (its 4 lines into Victoria) and on the other side eventually phase 4 will be there. Why not TBM the whole way? Well TBMs cant tunnel backwards (overrun tunnel). And as for the launch tunnel it just cant be done by TBM. The whole TBM is about 200m long and it all need to be laid out before the on button is pressed. Also, the TBM need to be able to grip the walls of the tunnel to push against meaning it cant be launched from the Crossover Box.

Jonny – good point on backwards TBM driving!

I think your points about SCL make sense – I was asking as we have a similar issue (ground movement) on Tideway but it is a different scenario so think either option is still sensible.

Regarding muck away – have you considered adding, rather than moving material – see Page 276 in this link for the use of camp sheds for barges.

Click to access Garden%20Bridge%20Environmental%20Statement%20Volume%205%20Appendices.pdf

Might be easier to get PLA and EA approval…

If all the piles are in London Clay do they rely on base resistance at all? Therefore perhaps you just need to re-create some resistance equivalent to the amount of shaft lost.

Or do you expect a reduction in shaft resistance due to the burrowing works disrupting ground above?

Jonny

A good blog. With your sprayed concrete Ryam McGuirk came up with the idea of using thermal imaging to see if the concrte is of sufficient strength in order to carry on working….do you remember a guy getting killed on his site as a slab of sprayed concrete fell of the tunnel roof

Kind Regards

Neil

Thanks Neil.

Damo, adding material would work but it would still limit the amount of barges we can have in at any one time. Long term plan is to have two in at any time, and at high water the tugs brings in two empty ones and take the full ones. Thats 4 a day(4000 tonnes) but with no scope ti increase. We are also installing a mooring buoy to assist in the change over of barges. But it means if we needed it we could increase to 3 or even 4 barges in at any time. The progress of the TBM is unknown but they dont want a limitation on dig rate due to the speed at which muck can be taken away. The £60,000 cost to increase the depth is well within the budget for the long term benefit.

Hi Jonny,

Nice second blog! I note that the muck away is at break even on 4 barges a day and can’t help wondering if transiting material from other sites locally from road to river might not offer a further reduction in road miles for muck away in the area and provide an income stream from an under utilised asset?

Hi Rich,

Well we are kind of already doing this on a smaller scale. We currently remove muck from Nine Elms (same project by treated as a separate site for commercial reasons). We have had to install a weigh bridge to measure the amount of muck we are accepting. All this is fine as it is ultimately all part of the same NLE project.

As for other sites. There is an issue about accepting some one elses waste. If there is contamination (concrete/ asbestos/ fuel etc) we would be liable regardless as we would be unable to verify the source. Also last week one of our belts got damaged when a piece of scrap steel ripped the belt (the steel shouldn’t have been there and initiated a whole issue about how we are separating waste and muck). But any damage would be our problem.

The solution (which is actually happening with Battersea phase 2) is a second conveyor that intercepts our conveyor on route to the jetty. This means;

1/ Phase 2 is responsible for the initial financial cost of a conveyor lift (a fraction of the £5m it cost the NLE).

2/ Then we would only be sharing part of our conveyor.

3/ One of the agreement is that phase 2 use the same contractor (Burrows Brothers ) to install and run the conveyor as we do.

4/ Phase 2 can then set up their own contract Goshems Farm.

5/ Phase 2 muck never enters our muck bin and is removed in separate barges.

6/ All whilst they pay us £29 a tonne (it costs us £16 a tonne) to remove material.

7/ GPS Marine retain their contract with us and an uplift in work.

This solution only works for a limited time (until the TBMs come online) early 2017. It has taken alot of pressure from Battersea Power Station Development and coordination to come up with this plan. But it seems win win all round.

Jonny, that is fantastic coordination and logic on removing spoil. Out of interest what happens to the muck when the TBM starts?

Once the Crossover box is completed a vertical hoist will join the back end of the TBM and bring up to ground level. Then it second conveyor (still to be installed) will connect to existing conveyor system. So, muck removal from TBM face to barge will all be automated.

Plan is to always have a barge in, however TBMs don’t stop once they get going. So, there is the option to divert muck to the muck bin to allow for down time to maintain conveyor system and change barges. At a rough guess we would have at least 3 days of space in the muck bin. Once all running again we can use an excavator to lower the level of the muck bin. It will require close management.

I assume any other use (i.e. phase 2) would need to stop.

Thanks Jonny. I was aware of the risks re ownership of contmaination and would have envisaged a need to maintain separation but this is heart warming stuff in terms of collaboration and sustainability.