Grab your Stetson and Run for your life..

Grab your Stetson and run for your lives!!! – BRISBANE CASINO TOWERS

What the client is selling it as.

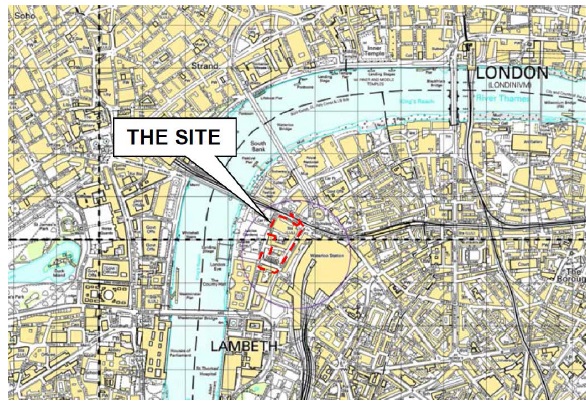

Introduction. So I started work at Brookfield Multiplex on the Casino Towers project on Hope St in South Brisbane. The project is a 30 storey residential tower block with 6 floors of basement. The contract is a fixed price Design and Build contract for Metro Property Development. BM has taken on all of the risk with this contract under a fixed price and a tight deadline. Time and cost are paramount with tough liquidating damages for overrunning, so the pressure is on. Much of what the project team do is manage other sub-contractors and liaise with their contracted designers. Location wise the site is situated in an interesting area between two blocks of high-rise social housing whose occupants are none to happy about our work and have been keen to let us know by throwing their used needles over their balconies and into our site.

The clowns to the left of us

The clowns to the left of us

The jokers to the right

Stuck in the middle in poo or Acid Sulfate Soil (ASS)

Contract out risk. At the moment we are at excavating the basement. The team has little to no experience of excavating basements and have sub-contracted this phase of a contract to Delta on a Design and Build contract. Delta in turn have sub-contracted the propping system to QPS, with Delta taking on the bulk of the mud moving for themeselves. Unfortunately BM sub-contracted the piling work out to Franki Pile and as the supports and wall work as a system are still carrying much of the can. Wailers are clashing with the future floor slabs and given that the site is at a slight angle, it has all got very complicated.

![Q2454-0001[01] (1)](https://pewpetblog.com/wp-content/uploads/2016/03/q2454-000101-1.jpg?w=595)

Prop Layout at first level of supports the remainder is Ground Anchors

Managing Sub-Contractors. While BM has contracted out the basement they seem to have little leverage into motivating the sub-contractors. They have been accused by the subbies of micromanaging but, it is clear that the subbies are not up to the task. The secant pile wall/propping system has not been designed for construction loads and we can’t even unload stores close to it. On the flip side it would seem that with only one engineer on the project up to this point the scale of the task has over matched him and BM have not asked the right questions before they got to this point.

Struggling to fit the whalers in place

Propping system. QPS are the subbies in charge of the propping system and are more used to ground anchor systems and have struggled with installing a workable propping system. This is the biggest job they have done and frankly it shows. My key criticisms are they insist on welding everything on site, as opposed to preparing off-site and connecting with bolts on site. At the last count 9 of the first 10 welds have failed and need to be redone. They have not really thought about how it will go together and many items have arrivied out of tolerance. The project is now about a month behind schedule. I took a ride out to their fabricating facility. There is a huge capability gap from what we saw at Nu-steel and what QPS can produce. The whole prop system should have gone in last week but the wailing system still hasn’t been fitted. The picture below shows Delta struggling to get the end wailer into place.

The journey of the whaler from factory to floor

H&S. So there are so many issues I scarcely know where to begin. My first appointment was at BM headquarters in the Central Business District. The meeting was about enforcing stricter H&S standards on the various sites around Brisbane. The overarching thing was about moral courage (where have I heard that before) and about safety in design. Monday was a scheduled no work-day so I had the opportunity to inspect the site without any of the sub-contractors (or unions) around. The sub-contractors approach was certainly different from anything I has seen in the UK’s. The stairs into the basement had been undermined by the heavy rains and were pretty rickety. I was also struck by the confined nature of the site and the little separation of people and plant.

Our Union Rep checking H&S standards -integrity is not his strong side. You can see the plunged columns that will support the working platform.

Labour disputes. There have been real issues with unions in Queensland. At the start of the week a construction site on the next street had been shut down after a union walkout. By Tuesday, it was our turn with the union rep/commissar proving his wide and diverse vocabulary regarding his concerns about H&S on site. The union used the rickety stairs and the lack of any other alternative exit to shut down the site and to be fair he had a fair point. However, you can see the reps keen interest in PPE as he encourages the Delta employees to ‘knock off’ for the weekend on Friday.My role – Resitting Exercise Cofferdam, working out how I can get an excavator to move the ASS without exceeding the maximum surcharge of 5 KPa within 3m of the wall.

Boundaries, Properties, Groundwater, Contamination…Constructability!

.

.

Hi Doug, sounds like you have a tough but likely to prove useful site. If everything went perfectly you would have less to write about! It seems it is all about towers this year! What depth is the excavation going to? Why was the waler beam not chosen as the capping beam? Looks like a fairy hefty set of water beams so I presume pretty deep.

Do you have a propping scheme layout drawing you could post?

Have the ground bearing piles already been cast or are some going to be installed from the formation level? If yes and all done from ground level, are you having to break down piles with reinforcement in?

Regarding delays, how did this company win the tender being so low in competence/experience, was it case of cheapest won? I assume BM have loads of projects upcoming so could they apply pressure to speed up/improve quality or tell delta they might not be getting much work in the future from them?

Hi Damian, it is a great site there is so much going wrong I have enough to write about for years. The excavation goes down 18 m, However, the secant piles go down to 23 m to cutoff the site from the aquifers that run to the river otherwise we would probably need scuba gear now.

They wanted to avoid any whalers clashing with the slabs so they didn’t want to place the capping beam so high. I think they wanted to minimise the amount of propping. The tend to use more ground anchors which are considerably more efficient. I had problems loading the prop schematics from PDF but will try again tomorrow.

With the exception of a plunging column that will support a working platform at street level, there are no piles. The building will be supported on pad foundations laid onto the phylite bedrock.

Delays – This is the second contract Metro has given to BM. BM has won a lot of business lately and is experiencing growing pains. Many people are doing their jobs first the time, so that naturally raises issues. Delta the sub-contractor have substantial experience of doing basements and mining but, props are not that the common way of doing things here. Delta’s sub-contractor are more used to ground anchors and I there is not the proprietary propping systems that you might see in London.

Things have moved on since I started this – BM is livid with Delta and we are monitoring progress on a day to day schedule. It is a small world in Brisbane and people don’t like to pursue LDs but, Delta are now on notice.

We have potentially solved the trucks and dogs issues (unloading). More to follow.

Didn’t intend to steal your thunder about the unions Doug. I sense it is an Australian wide issue with state nuances. We were very close to a union walk out on Monday – any cynic might suggest because the top union rep was only flexing his muscles and puffing out his chest a little; he was require to stay an extra 30 mins than was anticipating on Friday due to a slight delay in pouring one of the 2100mm piles! It was avoided, narrowly. We did have the sub contractors ‘heated off’ today because we hit 35 degrees. Im finding it an interesting relationship which I will be watching closely.

Agreed about BMC being construction managers. They have won D&C for Australia 108 and all sub-contracts are the procured in the same fashion. Rightly so. Although it does surprise me the faith they seem to put in the sub contractor getting it right. Any questions raised usually gets the response, ‘its their problem’. Yes, the subcontractor holds the design liability, but if anything substantial goes wrong , it will cost time and money. As you said, the liquidated damages really do add up. Enough said on that as even after a week, I could write for hours on the relationships between the BMC and their subcontractors, including their programming!! Maybe I will, but not tonight.

No worries Jo – You are spot on as usual. Apparently NSW have it better but QLD and VIC are both bad. As much as our rep is a pain in the arse he has forced the subbies to clean up some of their act. Safety barriers are going in and the site is becoming gradually less lethal.

Doug, I think the H&S aspect of Ph1 leads us to believe that people should go no where near anything with an engine. The whole issue to separating plant from people is not so easy to achieve and I suspect your site has many similarities to damo’s. Clearly space was not an issue on my river banks but as soon as we moved over the water we had plant and people working in very close proximity. The management of it was a nightmare and required constant attention. We ended up in a situation where safety barriers were enhancing the risks so we removed them from the jetty. we had to enforce a number of movement checks and further levels of warnings and improve comms. Keeping on top of it slowed the progress dramatically, far beyond the extra time that had been factored which clearly carried a cost however, I don’t believe we placed anyone in any extra danger.

Competition anybody?

When Doug puts up the wale/prop arrangement consider the following:

The factored wale load is 300kN/m ( albeit I cannot see a surface level temporary work surcharge in the wall assessment

The size of the excavation is approximately 40m x 34m

The wales are twin 1200WB 278 ( you can Google these)

The props are 900 dia 15mm wall CHS

What do you think?

Oli, Great to hear from you mate. I get what you are saying but I will put up some photos and you can make your own mind up with. To my relief the barriers are now protecting the stairs which was my key concern.

John, The first question I asked on site was what vertical load was it designed to take – first response but, it does act in that way. Good job I asked as it is now being used as a temporary works platform and has handrails. The General Arrangement has now been added.

Does anyone have the IHS logins? I still haven’t got all my shipping yet and am currently without my notes. Although CIRIA C580 is now my bible.

John, my come back…

Firstly, wow! I did not picture that layout. Doug – any chance of a picture of better quality?

Props. Taking the long side I crudely get about a 5m spacing between them, although not sure what is going on in the middle. I assumed the props would go across the site, perhaps this method gets the core away and was the bit missing from Two Fifty One.

Prop stiffness, AE/L gives 515kN/mm. At 5m spacing, 300kN/m x 5m = 1500kN axial force. So deflection of wall approx. 3 mm. Seems acceptable as there are buildings close by.

The axial force resistance with buckling length considered is likely to be much higher than 1500kN for a 900mm section, therefore I would remove the 2 additional corner props and space out the main diagonal ones to about 10m spacing. I would put in some targets on the capping beam and nearby buildings, take daily readings during excavation and be prepared to stop and add props if necessary/triggers levels reached.

Waler beam

Waler beam 1200WB 278 has a moment capacity of σI/y of say 355 x 2 x 7610×10^6/585=9.2MN

Load on waler modelled as a UDL (waler load) on 2 supports (props) as a simply supported beam, that would give WL^2/8 = 300 x 5^2/8 = 1MNm.

Therefore the waler beam is very, very over designed unless I am missing something. The amount of web stiffeners should sort out any local buckling.

Thoughts – Why the double waler beam? One would be more than sufficient if braced from rotating over. It seems a strange shape when a 900 CHS will overhang the beam (700mm double width) unless there is some sort of reducer piece. If the waler were less deep and a bit wider that would seem more appropriate as the depth is not really needed in this configuration.

Howdy Partner, the furthest distances between props is 10,048 mm in between S1a and S2 in the top left hand corner on the longest side or as I call it smackhead corner. Longest prop is 26.3 m. I think the double waler was built to take the prop coming in and not the load. I agree though if you remove the corner pros you are left with approximately 10m spaces and it should be able to handle it.

The load in this part of the wall is 380 KN/m which doesn’t really alter the price of fish. I have the prop taking under 5 MN but having a capacity nearly 3 times that. I have lost faith in the structural engineer who signed off this support system.

I am running it all through on STAADPRO tomorrow. Given the time taken to weld. It may be worth getting them to sign off the removal of the corner props. So once I have built the model I will be better informed to open up my side of what can be done. Also I am looking for a penetration so I can run the concrete pipe through.

NB. Props are at an odd angle to deconflict with the columns coming up.

On a different note, in the meeting the other day the geotechnic looked over at my notes and said you know your wall design. So John, you must be doing something right.

More to follow on the acid sulphate soil (ASS) in ‘Hauling ASS’

Damo – even though the prop spacing is more than you’ve guessed; I think most of your anlayses is so the money; I question the double wale and the prop distribution; As Doug says the prop positions may be selected to deconflict with the column positions but this still does not explain the near corner knee braces. All good stuff for Doug though.

Hi Doug,

Ignoring the proplayout is clearly to suit proposed srtucture and the steel for the whalers appears to be specificed as 250N/mm2 discussion entirely: How does the union reps right to enter site at will and not wear PPE get enshrined in the contract? Presumably there are different rates for active on site, rained/sweated off? In UK most sub -cons hate standing time because it earns less profit than active working.

The unions are extremely powerful around here. They tend to strike for ‘Safety Reasons’ so still get the same pay. There is a rep around here that is known as the 10 million dollar man as when he was in court for assaulting a female client – all of the sites in brisbane shut down and cost the qld economy 10 million dollars. The thing is Rich its not worth it at the moment and he didn’t get away with it for long before one of the site supervisors had a word. The strange thing is BM employs him in what I believe to be a keep your enemies close kind of thing. Every day we lose is $33K in lost revenue.

The subbies aren’t happy because they are on a tight deadline and LDs have been mentioned.