Moving to Site

Over the course of the last week it has been clear that 75% of the “Engineers” on this project are fixed by the processes around gaining permissions and submitting notices in order to comply with the Development Consent Order and Works Information. Consequently a lot of the detail for our move to site has gone unexamined, good for me in terms of the experience I’ll get, but potentially bad for the project because they actually seemed to have believed the rubbish I put in my CV.

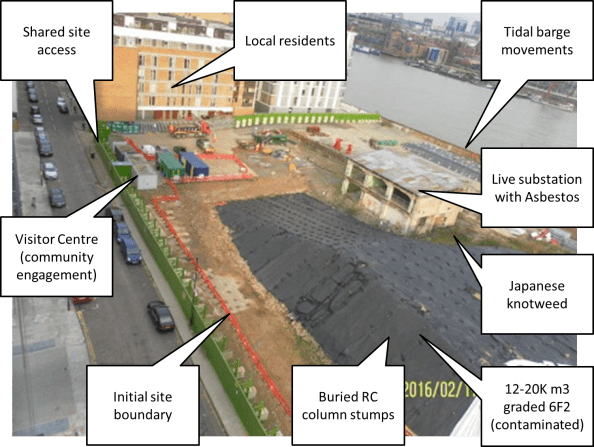

My team assembles on Monday to start the early works and the figure below shows some of the frictions that we will have to deal with.

Figure 1. Site “Frictions”

Liaison with Neighbouring Works

This looks like it could be pretty messy. The initial CVB site boundary will roughly follow the line of the orange Chapter 8 fencing, CVB will control site access from the road and are responsible for security to the entire perimeter (including the parts within others PCs areas. As the stockpile is reduced we will expand our site (land/insurance permissions will take at least a week to be circulated before I can move a fence). Eventually we will get enough land mass to start work on the foundations for our office block (in the location where the green and blue containers are).

Local Residents

There are a number of restrictions on site activities owing to the clauses within the DCO. Noise planning and emissions will be closely monitored for all site activities. Residents have a 24hr hotline number to call if they have any issues with noise. We also have to maintain a visitor centre on site which we man on Wednesday evenings, and hold fortnightly Community Liaison Working Group (CLWG) meetings. The surrounding area is 50% expensive river front properties owned by influential characters (rumoured to include Captain Jean Luc Picard), and 50% social housing with a number of residents that are shift workers or unemployed and therefore in the property during working hours.

Stockpile Removal

Another contractor is responsible for removing the 6F2 stockpile from the earlier (2009) demolition works. Initially they had planned to load a 1000T barge each day, then changed this to two 500T barges. In the test run they managed to load most of a 500T barge within the tidal window before a hydraulic line burst. Consequently the estimate has been revised to one 500T barge per day. The works were further slowed by the discovery of suspected asbestos. Works to remove the stockpile have been halted since last Thursday whilst we await confirmation. Perhaps a coincidence but the asbestos was found by the contractor appointed to remove the spoil, and it could significantly increase their fee if the waste was reclassified as containing asbestos.

Concrete column stumps

The contractor also discovered that the stockpile is hiding a number of concrete column stumps (approx. 600mm sq). The removal of these is currently within ‘a scope gap’ between the different PCs, however if it falls to CVB to remove they will have to try and do it ‘quietly’, due to the restrictions of the DCO by progressively drilling and injecting an expanding composite to break down the concrete in layers.

Japanese Knotweed

An area of Japanese knotweed was discovered previously and has been receiving regular treatments, although it cannot be completely eradicated. This will eventually need t be removed to facilitate our new site access prior to the office foundations being constructed.

All of the above are fairly standard site issues within London, but nevertheless should generate some valuable learning over the next few weeks, and as I commented on Jo’s post, a lot of potential for neighbouring contracts to impact on our works. I should add that we receive a brief on the Contract Execution Plan on Friday so I hope to explore how we might deal with any delays caused to our project as a result of delayed enabling works under a separate contract.

Tony,

Looks complex. About the concrete stumps. Do you know how deep they go/ how much you need to clear? and is there a method of removing them.

On my site they discovered what looked like an old well that had been filled with concrete. Sonic testing indicated that it was 9m deep. The chosen solution was using a piling rig to place a casing around it and bored it out, in the end it got to 29m before the auger came out clean without concrete.

m wondering what method of removal you have considered?

Jonny, CVB are primarily hoping that it doesn’t come to them. So far the contractor removing the stockpile has only uncovered a few. The concern was that the extent of the columns was an unknown and in trying to break up the ones that they had already uncovered they had suffered a noise complaint from a resident (these are discussed at fairly high level meetings). I completed a desk study by overlaying the location of the stockpile on the historical drawings from the CDM H&S File. This showed that the source of the columns was likely to be restricted to only one historical building in the SE corner of the stockpile.

From the rough levels of the columns uncovered so far it seems like we only need to reduce their height by about 700mm. Pending further detail on the columns once they are uncovered, and whether or not the job does fall to CVB we are looking at non-explosive breaking (something like this https://www.youtube.com/watch?v=mqRivEbv_7Q). Despite requiring drilling, and even if it needs to be done in several sections, and takes a few days, it would still be preferable to using mechanical breaking, given our noise/vibration restrictions.

OK so this answers my question about the residential alongside your site! Lots of standard simple challenges as you say and they all combine to greater than the individual contributions. HOw does the stakeholder mangement plan look and is it communicated between the various PCs i.e. is there a co-ordinated effort or is it all individual best effort? I would have thought the noise of some plant nibbling down a column stub was pretty insignificant compared to loading and then tipping 6F2 into an empty barge? Or is that the next step after a gentle honeymoon period?

Richard, The stakeholder management plan is co-ordinated by all PCs jointly, and there is very much a combined project face when engaging with the public, rather than separate engagements. The Community Liaison Working Group meetings are attended by Southwark Council, PMs from Tideway (Client), representatives from the PCs, Tideway’s comms team, legacy team and TAPs (trigger action plan) team. The TAPs team are delivering projects such as secondary glazing in properties that have been pre triggered as requiring additional noise reduction measures, and there is also a pot of money for additional measures. I’ve been told that at some point i’ll be thrown into the lion’s den as well so I’ll have to temporarily tone down my responses from fully Strachasperic, and deploy my full suite of empathy. On a serious note, I have been surprised by the level within the project team that the public comments reach. The public impression of this project is very important to senior management.

I’ve also been put on the rota for the Wednesday night drop in sessions for the public, so if anyone wants to come and whinge……

Ref the comparison of plant breaking concrete vs. tipping 6F2 into a barge, I suspect it has to do with our forecast of the noise that we expected to make and when, and that the columns were not known about so would not have been in this. However, I’m talking to our Environmental team on site next week so i’ll be able to give more information on this then.

Thanks,

I suspect that the need to uncover the columns means it will be dealt with when there is plant moving and loading 6F2 such that a little bit of concrete nibbling will pale into insignificance! Lets wait and see.

Tony,

Interesting site management issues all in one photo. With your permission I would like to use this photo on the next set of course when we come to the site set up/ management exercise? This demonstrates real time SHEF issues on site.

Regards,

John