SIMPLE SOLUTION TO A SEEMINGLY SIMPLE PROBLEM?

So drilling through a basalt extrusion proves rather problematic when the drilling arm to your rig snaps off and you are unable to recover it. You are essentially left with a snapped arm 20m deep in what should be a 1500mm pile which is now unusable.

The piling subcontractors are on a design and build contract; they caused the problem, they will fix the problem at their cost. The solution, endorsed by the Multiplex team overseeing this part of the programme, is to concrete the original pile borehole (BP38) and construct two further piles (BP38-1 & BP38-2) either side of BP38, designed to carry the same loads. Simples!!

What risk did they fail to see?

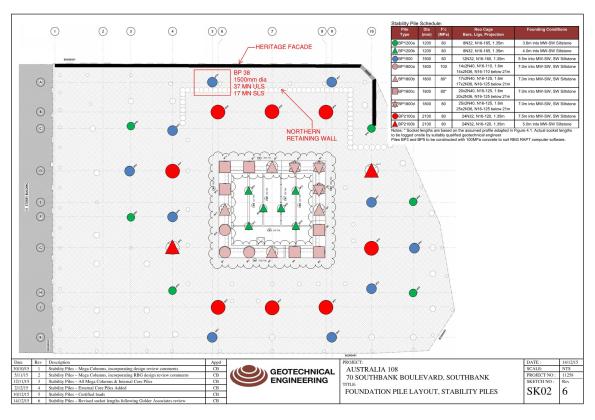

The position of BP38 is close to a secant pile retaining wall which is approximately 3.5m from the site boundary. There is a heritage façade which sits on strip foundations on the site boundary which is already in a pretty ropey condition and only supported laterally. The northern retaining wall enables excavation down to Basement Level 1. The construction of BP38-1 & BP38-2 was designed by the subcontractor’s engineer; construction went without a hitch and the two 1200mm bored piles have sufficient resistance equal to the original pile.

Position of BP38 in relation to site boundary and façade, and the northern retaining wall

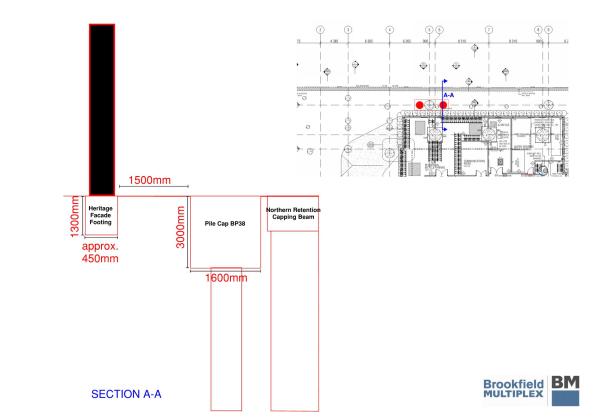

Problem: It turns out that when you adjust the position and number of piles beneath a pile cap it alters the pile cap design. Funny that! The structural engineer (a consultant) produced a new design for a 1.6m x 5.4m x 3m deep pile cap to ensure the load (37MN ULS axial load) could be safely transferred to the piles. This means that an excavation of >3m is now required to construct the new pile cap. This is a >3m excavation in soft Coode Island Silt within 1.5m of the heritage façade.

Cross section detailing the parameters of the problem

Unidentified risk: This is an obvious example of unidentified risk, which could easily have been identified. Two subcontractors responsible for two areas of design and construct have not communicated before adjusting construction plans due to a foreseeable problem – everyone knew the basalt was in that location. The geotechnical subcontractors have simply fixed the problem they caused, thereby fulfilling the terms of their contractual obligations, without due consideration for the next phase of the programme, i.e. the construction of the pile caps. Multiplex have ratified the change because, I would argue, the people overseeing the construction have not understood and/ or identified the second order effects of the change.

Discussions: The first time I was enlightened to the problem was when the co-ordinator (construction manager) overseeing this phase of the programme sat getting rather stressed at how he was going to solve it. After two hours of ‘it will be fine’ and ringing round for advice he sent me the specifics when requested to have a look at. Two heads are better than one.

Options on the table:

- It is obvious that the excavation cannot be conducted to that depth without retaining the ground which supports the façade. But the question was how? My recommendations:

- a) Stiff retaining wall functioning as a cantilever capable of withstanding lateral earth pressures and deflections (combi wall perhaps?). This would give clear space in which to excavate at the front of the wall but would require greater efforts to construct such a substantial retaining wall. Also very risky due to the absolute necessity that the façade cannot move.

- b) Prop a sheet pile wall using ground anchors so the load is transferred to the ground behind the wall. Due to the proximity of the boundary (<1.5m) I deemed this infeasible; there would not be sufficient space within the boundary to fix the anchors behind potential slip surfaces.

- c) Prop in front of a sheet pile wall bracing against the northern retaining wall. This is very feasible ensuring that sufficient space is retained to permit excavation.

- Review the pile cap design with the intent of reducing the depth of the pile cap and subsequent depth of the excavation. This may have been an option prior to the construction of the two piles, but unlikely to be feasible now the location of the piles is fixed. A retaining wall would still be required but to a potentially shallower depth.

The solution: I recommended Option 1c as the way to go, pushing the piles where possible rather than vibro. The piling subcontractors are responsible for the design and construction of any temporary works to enable the excavation but were holding off to receive direction from Multiplex. Multiplex in turn has sent the problem direct to the geotechnical engineer consultants for their advice. Their recommendation: Option 1c.

Timing: The problem was first identified by the groundwork subcontractor on receipt of the new design drawings of the pile caps. This was on Friday, nearly three weeks after the failure to construct the original piles. Construction of the pile cap was due to commence on Tuesday giving 1 working day to come up with a solution and have the designs authorised. Needless to say, it is now Thursday and the team are still waiting on the design from the piling subcontractors and work is yet to commence on the retaining wall.

Lessons learnt?

- Communication is vital when the work being conducted by one subcontractor affects another.

- Second + order effects must be considered prior to making any amendments.

- Identifying risk early and consider this risk in re-mediation plans.

Additional remarks: In this case, the solution would likely have still been the same had the problem been identified when the original pile was deemed unusable. The upshot of early identification was that a retaining wall could be have been designed early and constructed immediately after the piles, thereby causing no delay to the construction of the pile caps.

Jo, can you expand on why the new pile cap is so deep? How deep was the original one supposed to be? Did you say before piles are working more in base than shaft? Clearly 2 x 1200mm piles compared to one 1500mm pile gives much extra capacity… are the bored to the same depth?

Jo, I can’t seem to enlarge your photo’s, it may just be this computer. pile 38 seems to be quite a way from the larger red pile. do 38 a and b act as a small group? are they in any way tied into the original one with a pile cap?

are you expecting any movement in the silt (settlement) over the duration of the project?

I experienced a very similar problem. one of the piles below the rive pier collapsed before they reached full depth. to try and stabilise the area they pumped it full of concrete. two new pile locations were designed to share the offset capacity but like, this required surprisingly large alterations to the pile cap. both of these new piles failed when they tried to auger as the concrete had bulbed into their path. we ended up re-auguring the original location through concrete which took a long time and damaged a lot of kit but meant we could revert back to the original pile cap design. all of this was at the subbies expense and we also hit him with a massive delayed charges claim to which he barely put up a fight against.

Jo, Great blog, and nice and simple so retards like me can follow it. In my mind this illustrates a point that Steve made a few times, that you can never completely pass the risk to a subcontractor. Yes, it was their cock up and the piling contractor will suffer additional costs but there are also likely to be costs to other parties that cannot be recovered. I can see a number of situations on my site where we could have similar second order impacts.

Interesting. Close to Damian’s heart I would think after he lost a pile on site and a similar solution was leapt at as an easy quick fix (albeit expensive). What is the centre to centre seperation on BP38-1 and BP38-2? How would you model the pile cap? Assuming that you find you do need a 3m deep pile cap (really?) what will sit above it after construction – could it be formed higher up?

Jo

What would help put your blog across more easily would be a cross-section drawn to scale rather than 1500 mm being the same physical length as 3000 mm.

Kind regards

Neil

Acknowledge everyone’s comments – as I said in my first blog the piling has not been my responsibility and I’ve just made it my business to keep sight over what is going on for education purposes. There are no engineers on the team so any questions of a technical nature are always met with a blank look and a shoulder shrug. They don’t necessarily know the load configurations and how loads are transmitted either. If the engineers tell them it works, that’s good enough. The blog was also not intended as an in depth technical analysis of the pile configuration which is why I didn’t put too much information on this. It was meant to be about the importance of risk identification and whether or not you can really ‘pass’ the risk through contracts, as well as the importance of communication to avoid issues. Having said that, I will provide more information on the technical specifics of the piles and their configurations and design when I get hold of the right information.

Thanks Jo

I recall you described the geo on your site and identified the basalt. We discussed that it was strength becuse it appears as an intrusive dome whereas basal=t is normally extrusive ( the faster a rock cools the finer the crystal structure) . IN any event it was there, identified and an accident waiting to happen

When I discussed with Daz about t whether there was a big issue in (tunnel) boring basalt he determined that ther wasn’t an issues as long as

a) the basalt was just that and not weatherd rockmixed with basalt

b) theat the deveil is in the dtail of keepiing a contstent – not too high and not too low drilling pressure. The minute you try to force it you get problems in TBMs

So the risk was self evident form the start and the specislist sub contract walked right into it

I know the sollution’s fixed but I feel I have to say this since ehn you all get my (long overduw SoftBottom retuns) To a group I’ve probably said that the pile cap details were crap. By and by and large the problem with piles caps is the anchorage length for the re-bar – so the depth is normally set by using the distance past the centre plus the cap depth to give about 40 dia + 150mm top and bottom cover… jst saying

ALso the ULS stress is might @ 20N/mm2 or so – no wonder the concrete design strength is so high